Transparent conductive material

A technology of transparent conductive materials and transparent substrates, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of low transmittance, unsuitable for display products, etc., and achieve good uniformity, Improved environmental stability and consistent impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

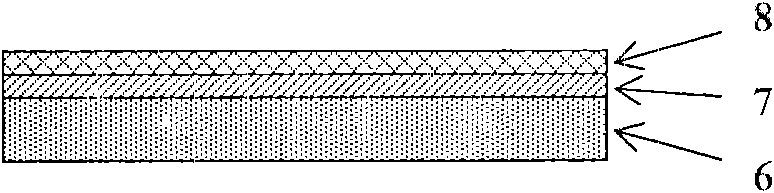

[0020] figure 1 It is a structural diagram of a traditional PET substrate transparent conductive film, which includes a PET substrate (6) and SiO on its surface 2-x Dielectric optical film (7) and ITO film (8). Of which SiO 2-x The role of the dielectric optical film (7) is to prevent the impact of outgassing of the PET (6) and improve the firmness of the ITO film (8). This kind of transparent conductive film is used as an electrode, and the part that needs to be etched changes its structure into a PET substrate (6) and SiO on its surface. 2-x A dielectric optical film (7) having a reflectivity significantly different from that of the unetched portion.

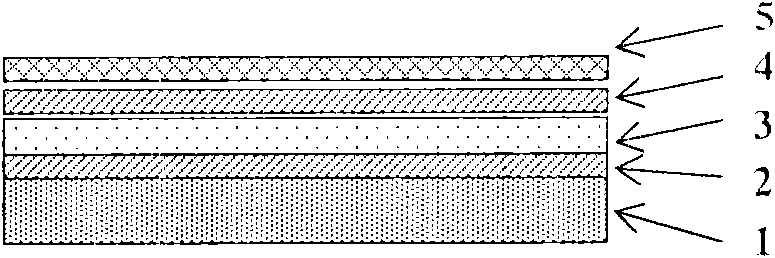

[0021] figure 2 It is the structure of the transparent conductive material of the present invention, and it comprises PET base material (1), and the first layer optical film (2), the second layer optical film (3), the third layer optical film (4) deposited on its surface successively ) and ITO films (5). The PET (1) can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com