Solid material surface transparent texture coating technology

A solid material, transparent technology, applied in the direction of metal material coating process, coating, ion implantation plating, etc., can solve the problems that cannot be used directly, and achieve the effect of beautifying the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

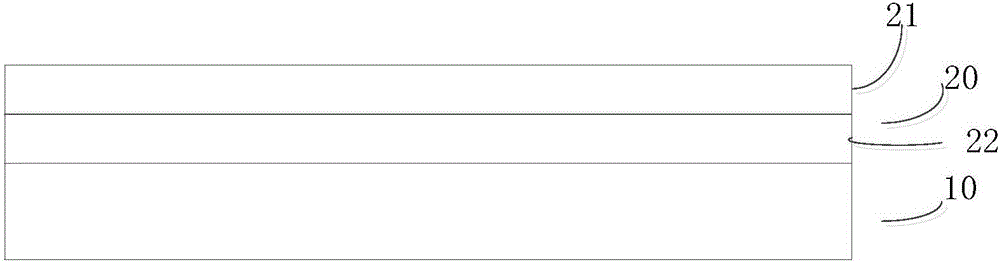

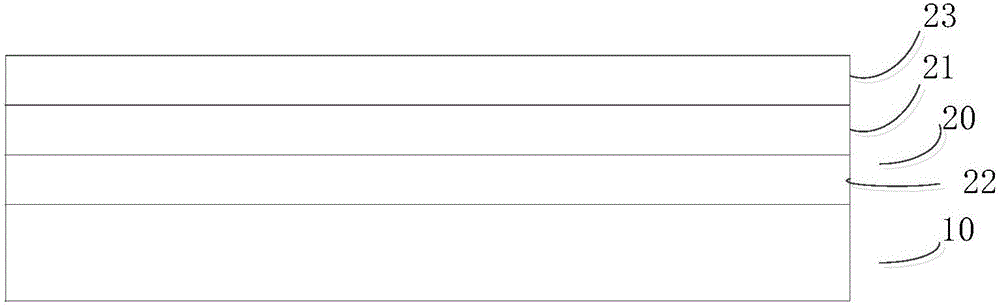

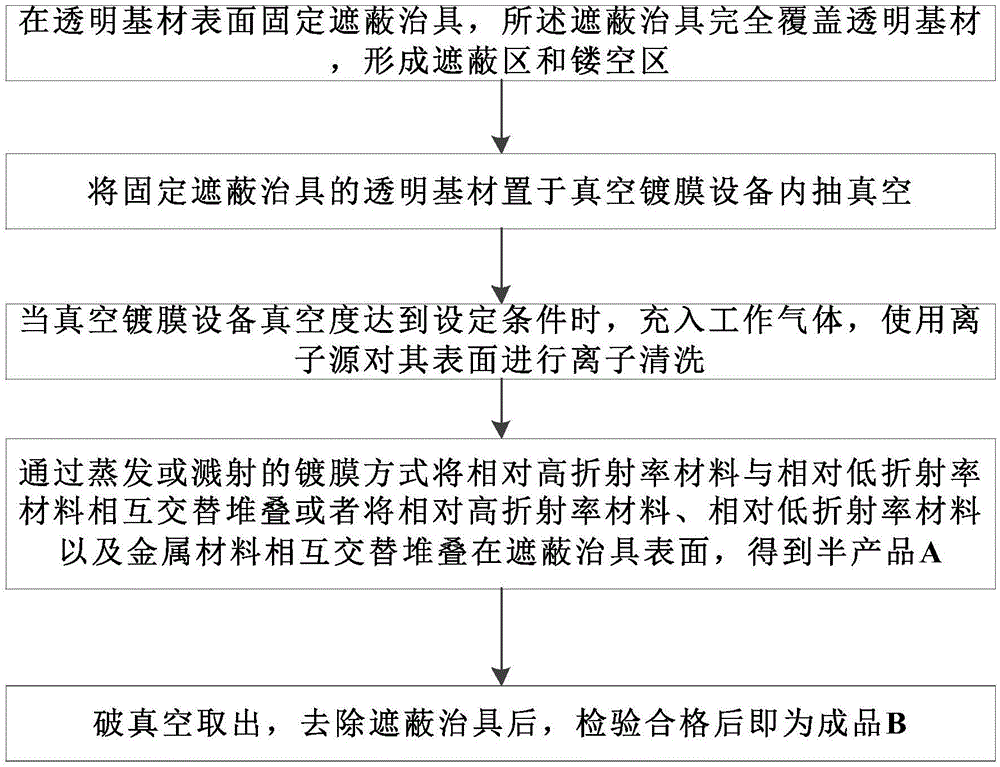

[0045] Such as image 3 As shown, the process for making a coating layer with an average light transmittance of 90.1 to 99.99% includes:

[0046] 1. Use screen printing to print a layer of water-based liquid peelable adhesive on the clean glass substrate A, and then dry it.

[0047] The peelable adhesive printed on the glass surface dries to form material B. Put the material B in the vacuum coating equipment to vacuumize to prepare the coating, and the side with the printed peelable adhesive is the coating surface.

[0048] When the vacuum degree of the coating equipment reaches the coating conditions (generally, the vacuum degree of the coating film is above 5.0e-2 Torr or 6.5 Pa, that is to say, the smaller the pressure value in the coating equipment, the better), first use the ion source to fill the working gas, The working gas is an inert gas. Perform ion cleaning on the surface of material B (cleaning time is more than 30 seconds, but the best is between 120 seconds an...

Embodiment 2

[0058] Such as image 3 As shown, the process for making a coating layer with an average light transmittance of 90.1 to 99.99% includes:

[0059] 1. Fix the clean glass substrate on the surface of the glass substrate with metal or plastic fixtures to form material B.

[0060] Put the material B in the vacuum coating equipment to vacuumize to prepare the coating, and the side of the fixed jig is the coating surface.

[0061] When the vacuum degree of the coating equipment reaches the coating conditions (generally, the vacuum degree of the coating film is above 5.0e-2 Torr or 6.5 Pa, that is to say, the smaller the pressure value in the coating equipment, the better), first use the ion source to fill the working gas, The working gas is an inert gas, and ion cleaning is performed on the surface of material B (the cleaning time is more than 30 seconds, but the best is between 120 seconds and 200 seconds).

[0062] After the ion cleaning is completed, the peelable adhesive surfac...

Embodiment 3

[0071] Such as image 3 As shown, the process for making a coating layer with an average light transmittance of 0 to 90% includes:

[0072] 1. Use screen printing to print a layer of water-based liquid peelable adhesive 2 on the clean glass substrate A, and then dry it.

[0073] The peelable adhesive printed on the glass surface dries to form material B. Put the material B in the vacuum coating equipment to vacuumize to prepare the coating, and the side with the printed peelable adhesive is the coating surface.

[0074] When the vacuum degree of the coating equipment reaches the coating conditions (generally, the vacuum degree of the coating film is above 5.0e-2 Torr or 6.5 Pa, that is to say, the smaller the pressure value in the coating equipment, the better), first use the ion source to fill the working gas, The working gas is an inert gas. Perform ion cleaning on the surface of material B (cleaning time is more than 30 seconds, but the best is between 120 seconds and 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com