Measurement method and implementation device of non-circular gear tooth profile total deviation

A non-circular gear and measurement method technology, which is applied in the direction of measuring device, electromagnetic measuring device, electric/magnetic profile/curvature measurement, etc., can solve the problem of high measurement cost, data processing software, complex non-circular gear tooth profile equation, and difficult measurement accuracy Guarantee and other issues, to achieve the effect of ensuring high-quality gear production, simple structure, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

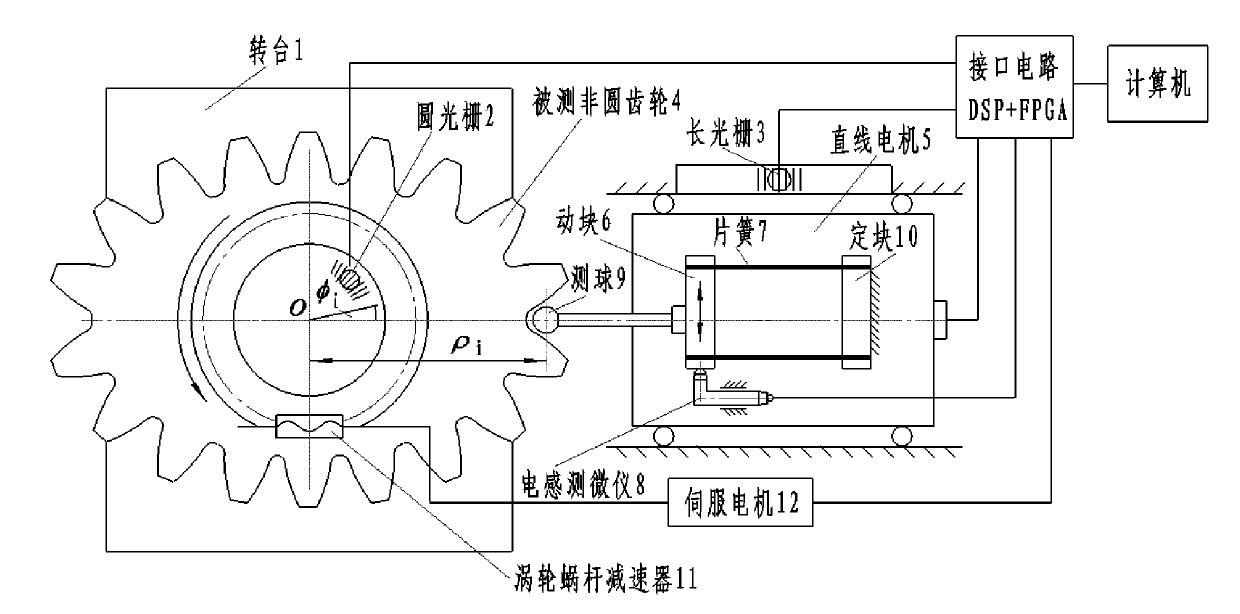

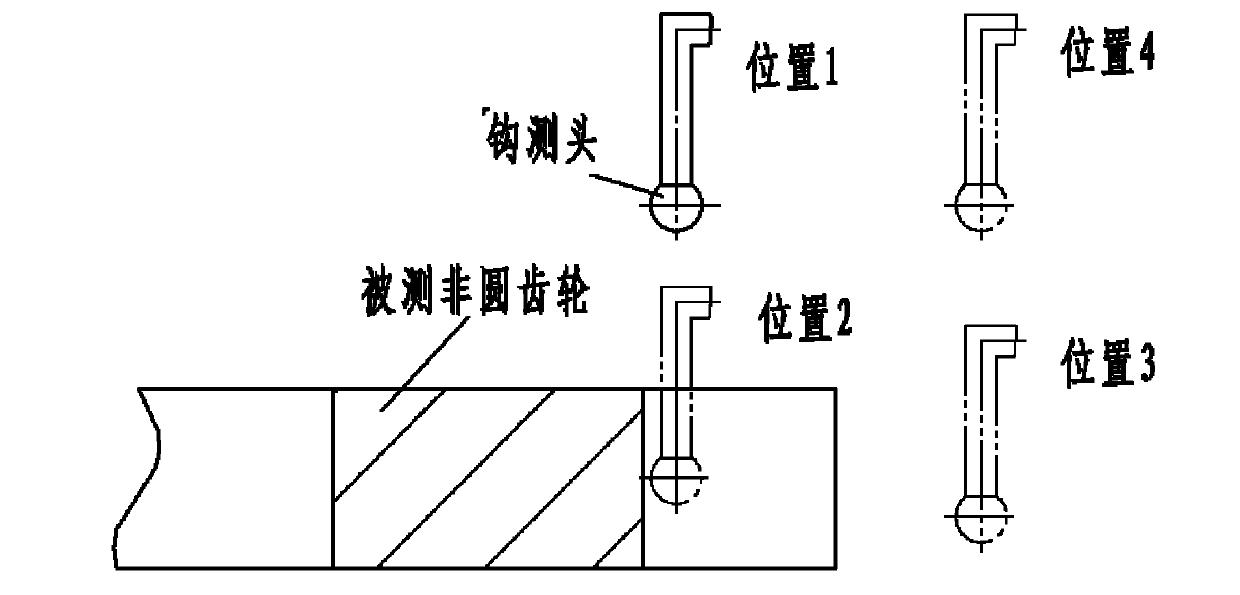

[0020] Since the pitch curve of non-circular gears is non-circular, the tooth profile of each tooth is different. The object of the present invention is to provide a method and device for measuring non-circular gears. According to the principle of polar coordinate measurement, the method adopts a tracking measurement method to measure the total deviation of the tooth profile of non-circular gears in the case of one clamping.

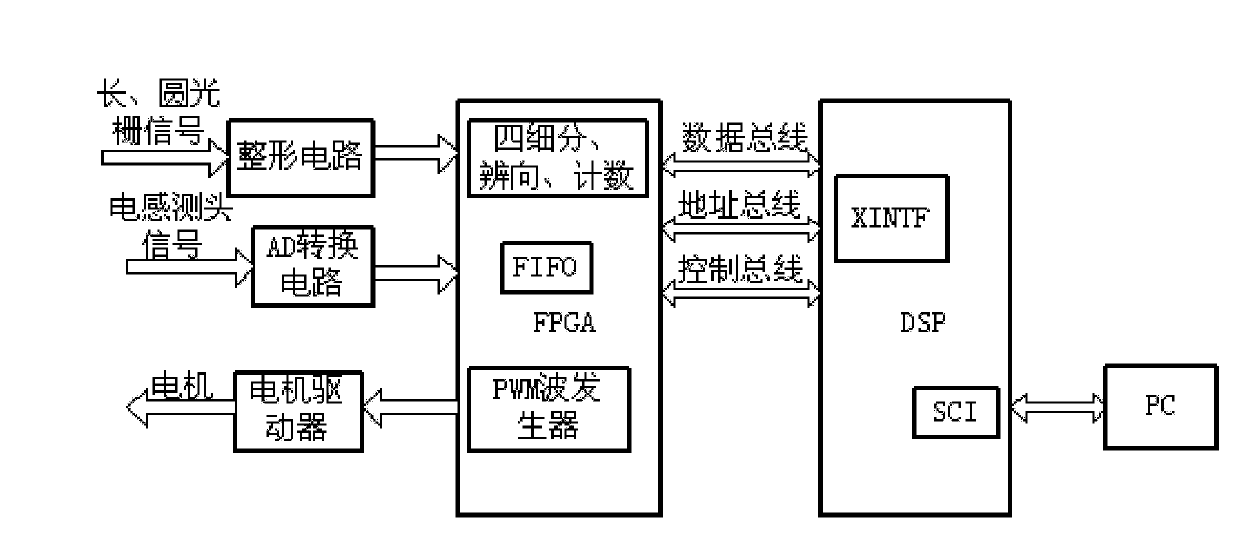

[0021] The measuring device of the present invention consists of a turntable, a micrometer mechanism, a linear motor and the like to form a polar coordinate measuring system. The long grating and guide rail of the linear motor are used as the radial reference of the polar coordinate measurement system; the angular reference is the circular grating on the precision turntable. The polar coordinate measuring system can measure the total deviation of the tooth profile of various types of non-circular gears.

[0022] With the computer as the core and a data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com