CNC machining center coordinate measuring method for 3D curved glass

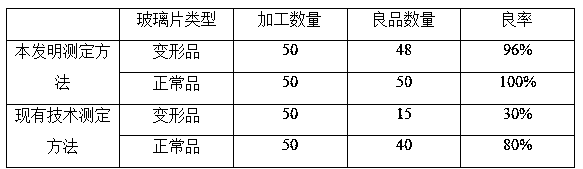

A technology of curved glass and machining center, applied in glass forming, glass manufacturing equipment, glass remolding, etc., can solve the problems of glass peripheral deformation, low production yield, inaccurate X and Y coordinates, etc., to improve the size Accuracy and the effect of improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] A method for measuring coordinates of a 3D curved glass CNC machining center, said method comprising the following steps:

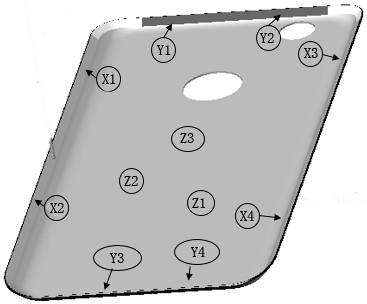

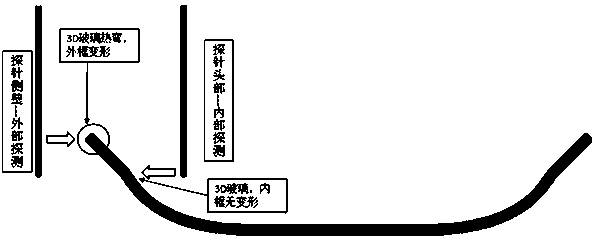

[0018] (1) Determination of processing Z coordinates: fix the concave surface of the 3D curved glass upwards on the CNC equipment table by vacuum suction, take any three points in the middle of the 3D curved glass, and measure the three points respectively through the test probe head of the CNC equipment The Z coordinate is Z 1 ,Z 2 and Z 3 , take the average value to get the Z coordinate of the machining center, which is also the safe detection height of the probe;

[0019] (2) Determination of processing X coordinates: Take any two points on the inner arc surface of one long side of the 3D curved glass in step (1), and measure the X coordinates of the two points through the test probe head of the CNC equipment as X 1 and x 2 , and then take two points on the inner arc surface of the other long side that is symmetrical to the first two points,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com