Infrared light emitting diode with strain compensation layer and manufacturing method thereof

A light-emitting diode and deformation compensation technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as deformation and efficiency drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, the present invention will be described in detail through examples.

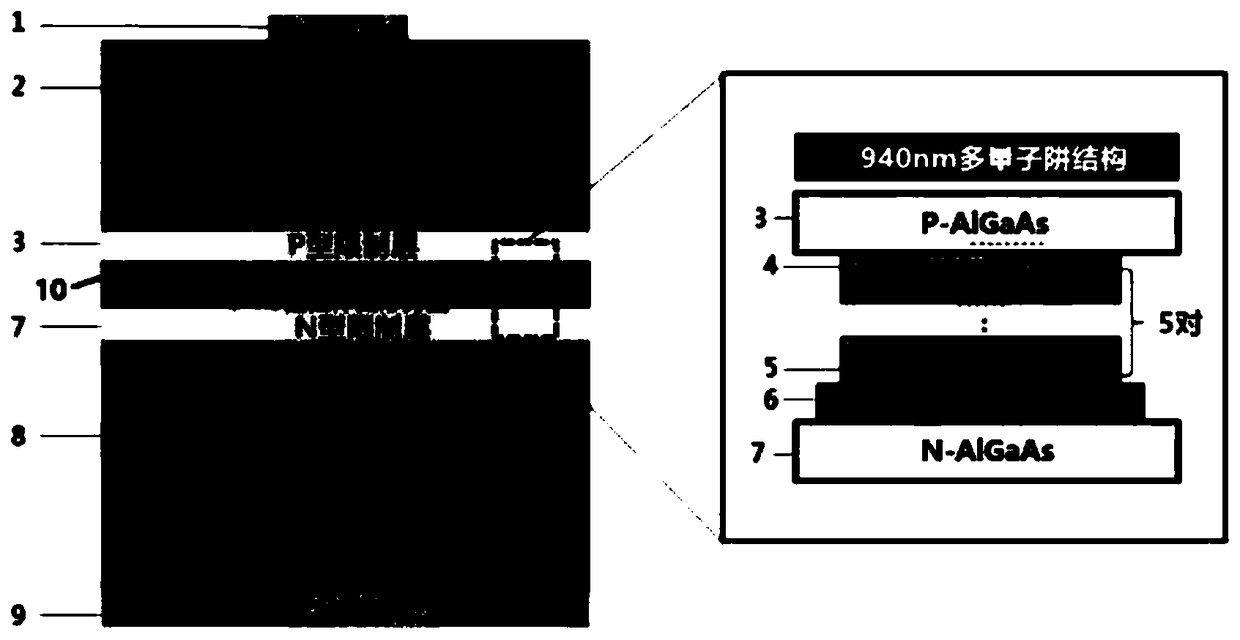

[0041] figure 1 shows applicable In x Ga 1-x 940nm infrared light emitting diode structure of P deformation compensation layer.

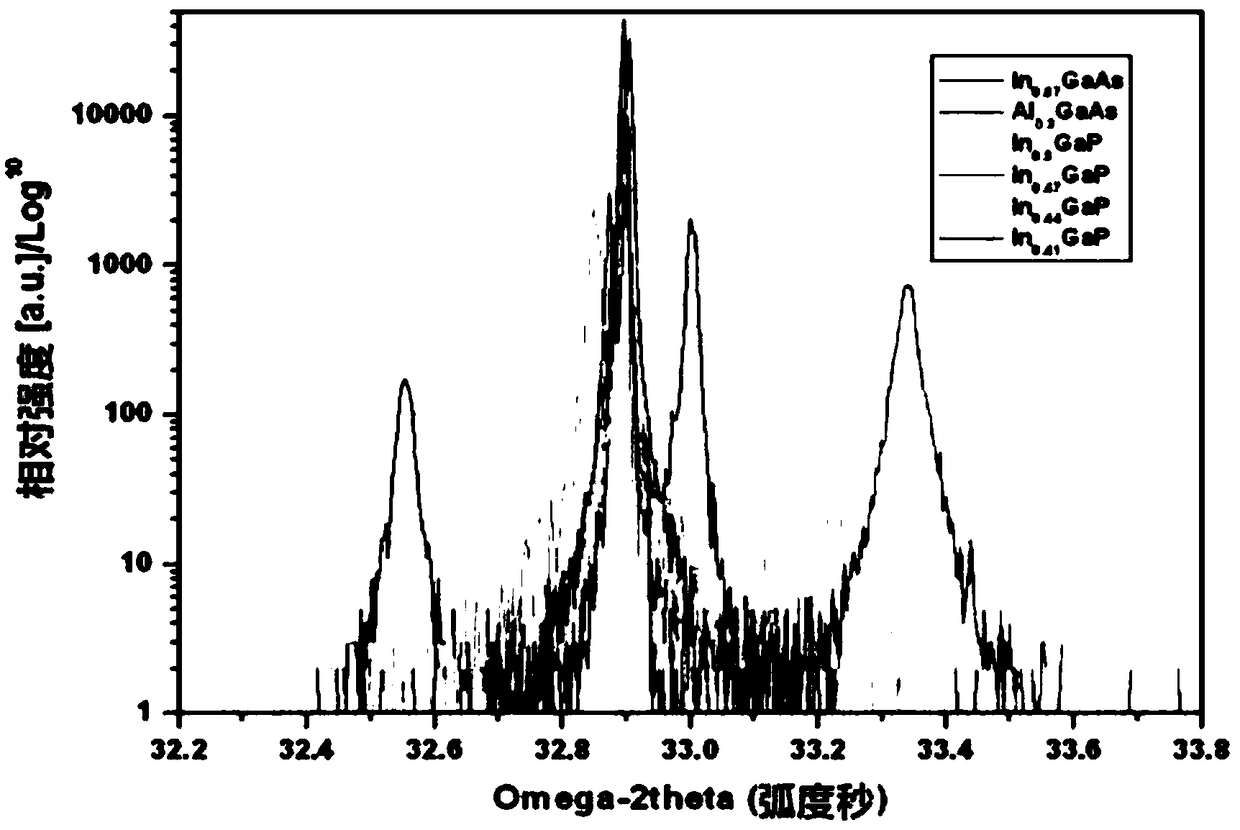

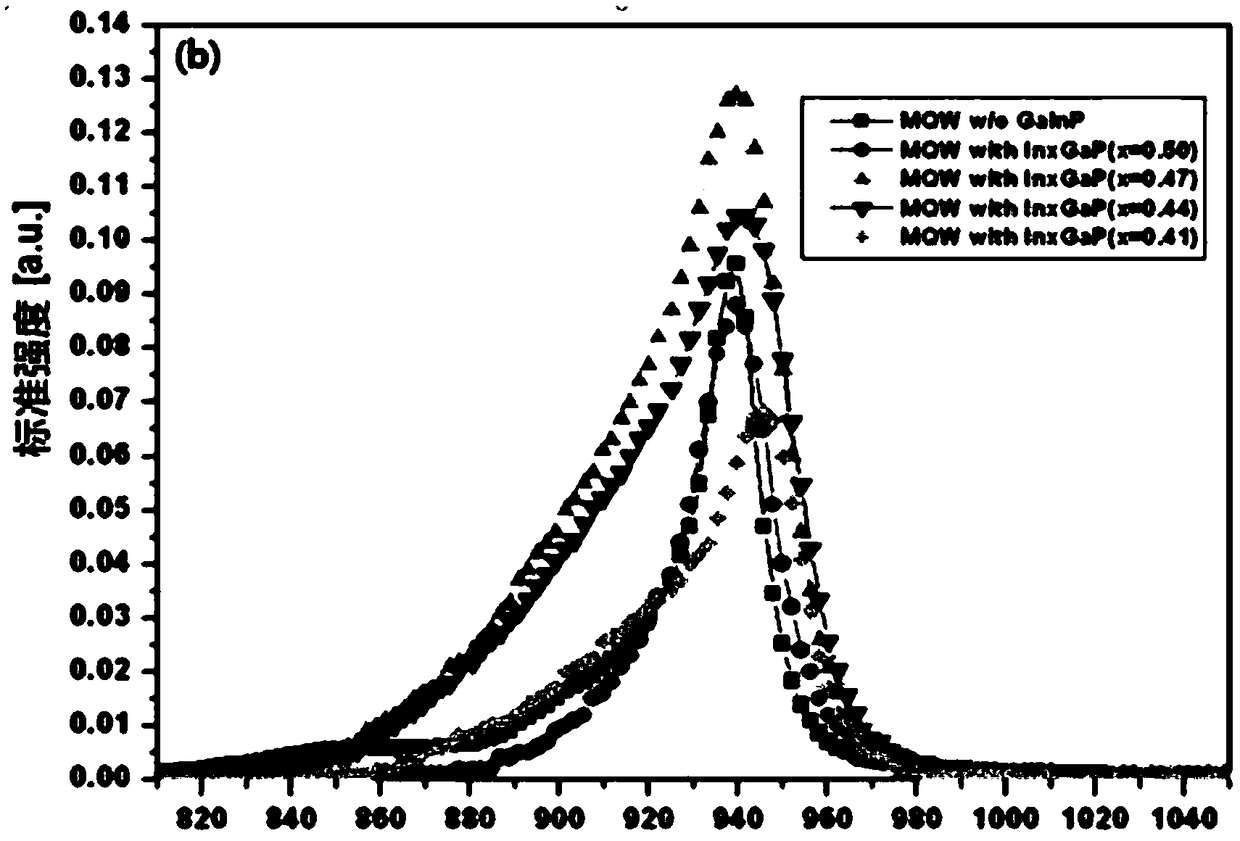

[0042] Such as figure 1 As shown, the structure of the 940nm infrared light-emitting diode is as follows: the n-type GaAs substrate 8 at the bottom, the Al substrate grown on the n-type GaAs substrate 0.3 Ga 0.7 An n-type confinement layer 7 made of As, and an In x Ga 1-x The deformation compensation layer 6 composed of P, on the deformation compensation layer 6 through the quantum barrier 5 composed of GaAs and the In 0.07Ga 0.93 The quantum wells 4 made of As are alternately grown five times to form the active layer 10, on which Al is grown 0.3 Ga 0.7 The p-type confinement layer 3 made of As, for the current diffusion effect of the infrared light emitting diode and the expansion effect of the emission cone area, a 5 μm-thick Al layer is grown on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com