Multi-point laser internal diameter measuring instrument and measurement calculation method thereof

A multi-point laser, laser rangefinder technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of being unsuitable for on-site measurement of large workpieces, low measurement efficiency, and few measurement parameters, and achieve fast and accurate measurement. Tools and methods, simple operation process, and the effect of eliminating human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and the embodiments.

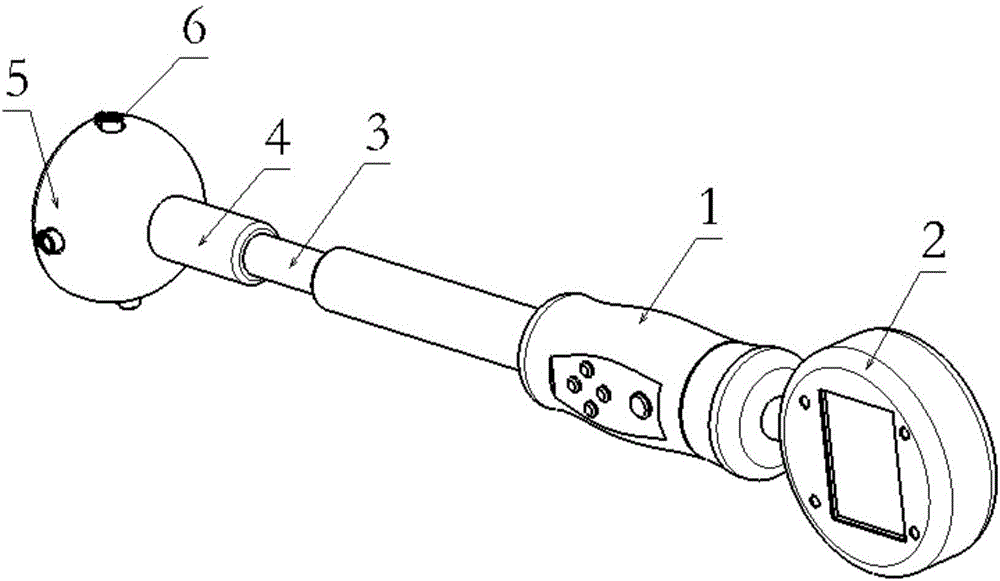

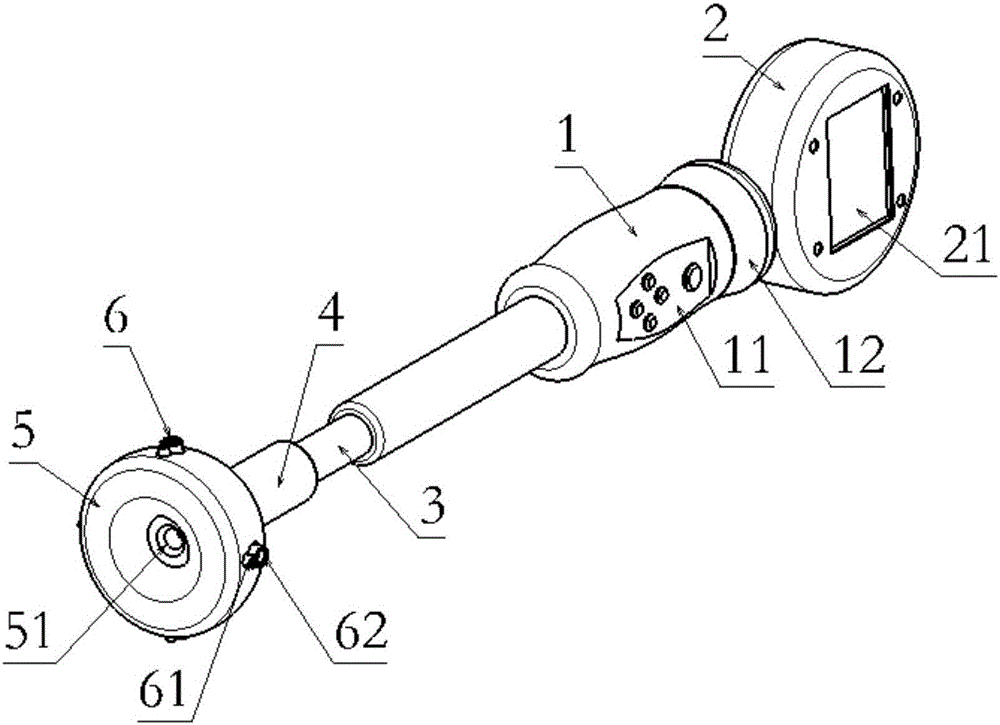

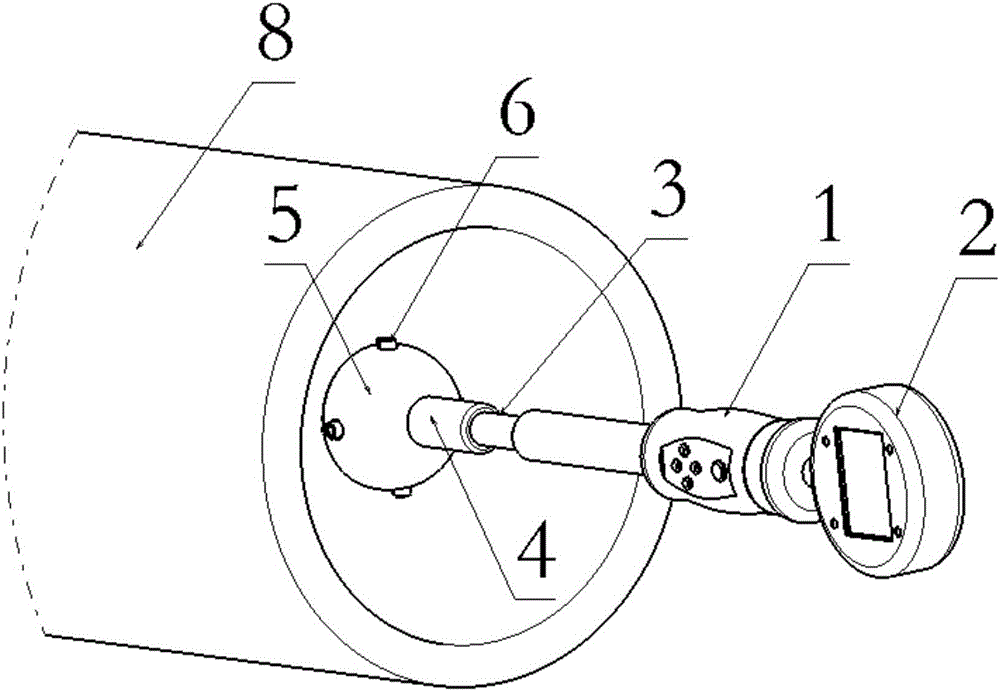

[0025] Reference Figure 1-7 As shown, a multi-point laser inner diameter measuring instrument includes a handle 1, a main control box 2, a connecting rod 3, a rotating rod 4, and a spherical probe 5. One end of the handle 1 is connected to the main control box 2 and the other end is connected to the connecting rod 3. Connection; connecting rod 3 and rotating rod 4 are connected by threads; spherical probe 5 has a flat upper bottom surface and a spherical bottom surface; the upper bottom surface of spherical probe 5 is provided with a connecting hole 51; connecting hole 51 penetrates through spherical probe 5, spherical measurement The head 5 is fixed on the top of the rotating rod 4 through the connecting hole 51 by screws; the spherical probe 5 is also provided with a laser rangefinder 6; the laser rangefinder 6 is located on the side of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com