Cantilever-type indicator thickness gauge

A technology of a gauge thickness gauge and an indicator gauge, which is applied in the field of cantilever gauge gauge gauges, can solve the problem that the thickness or depth measurement of workpieces with special shapes cannot be applied, and achieve easy direct measurement and comparative measurement, good practicability, and measurement wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

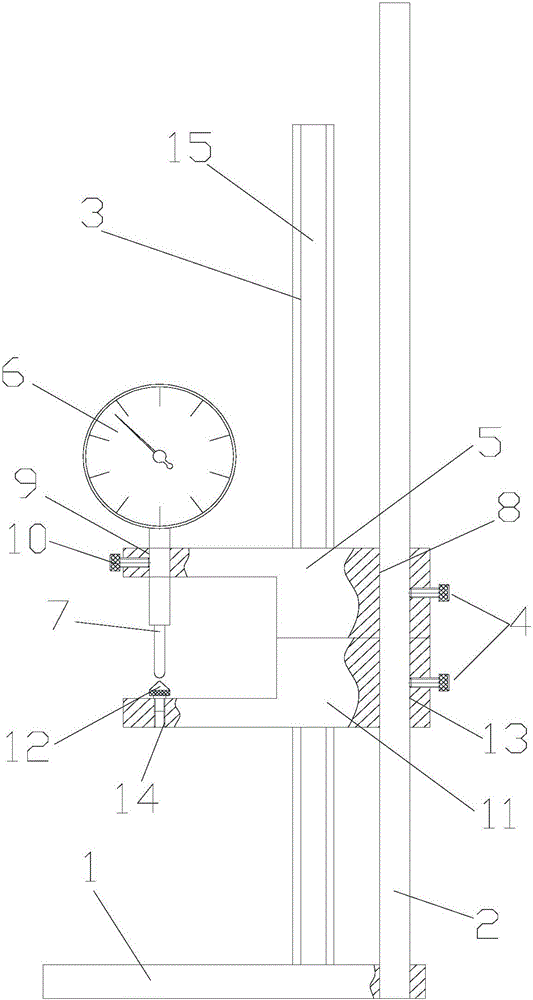

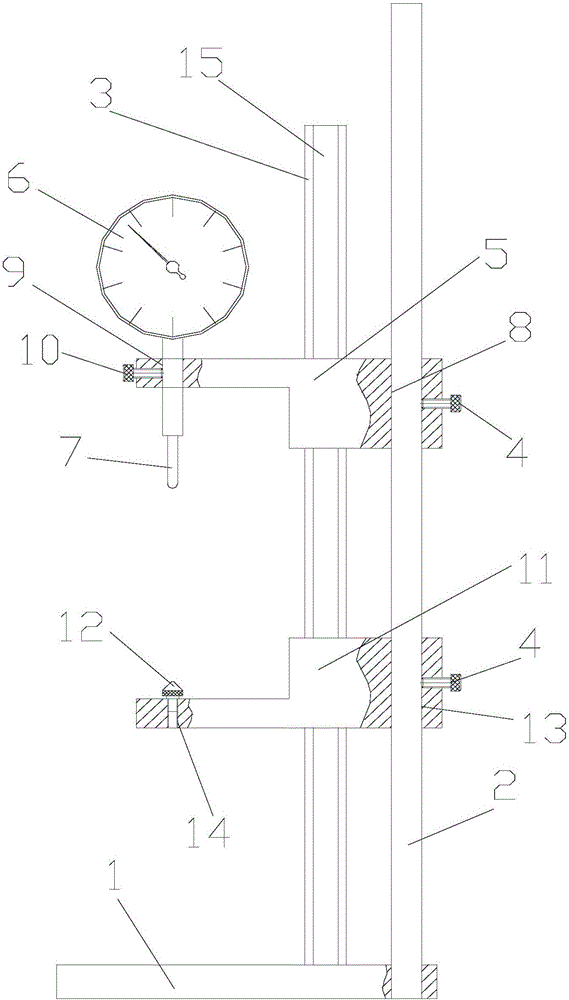

[0018] Attached below Figure 1-3 A first embodiment of the present invention will be described.

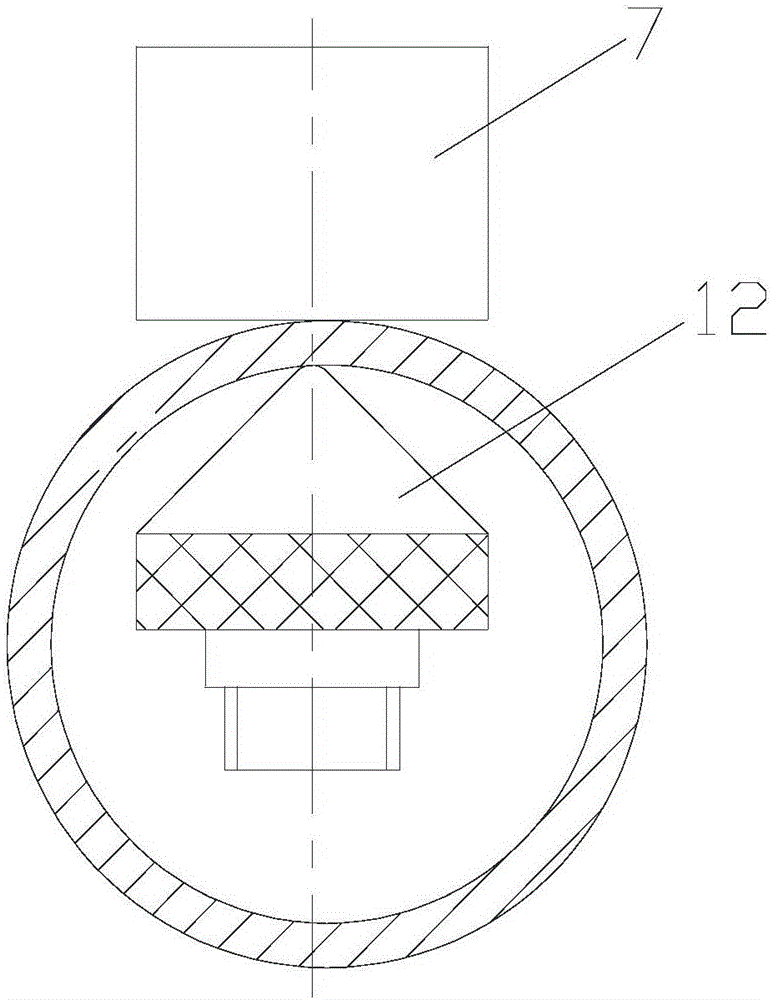

[0019] The cantilever type indicator gauge thickness gauge has a base 1 and a column 2, the lower end of the column 2 is fixed to the end of the base 1, and the indicator gauge lifting device and the spherical probe lifting device are installed on the column 2, and the indicator gauge lifting device is located on the Above the spherical measuring head lifting device, the indicator lifting device and the spherical measuring head lifting device are adapted to the guide column 3 fixed on the base 1 and then move up and down along the guiding column 3 to adjust their working positions. The indicator lifting device and the The spherical probe lifting device is fixed on the column 2 through the indicator table lifting device and the fixing screw 4 on the spherical probe lifting device, and the workpiece is placed between the indicator table lifting device and the spherical probe liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com