Inner hole fluted shaft direction dimension measuring implement

A technology of axial dimension and inner hole groove, which is applied in the field of measuring tools for the axial dimension of inner hole groove, can solve the problems of difficult measurement, etc., and achieve the effect of simple manufacture, low cost and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

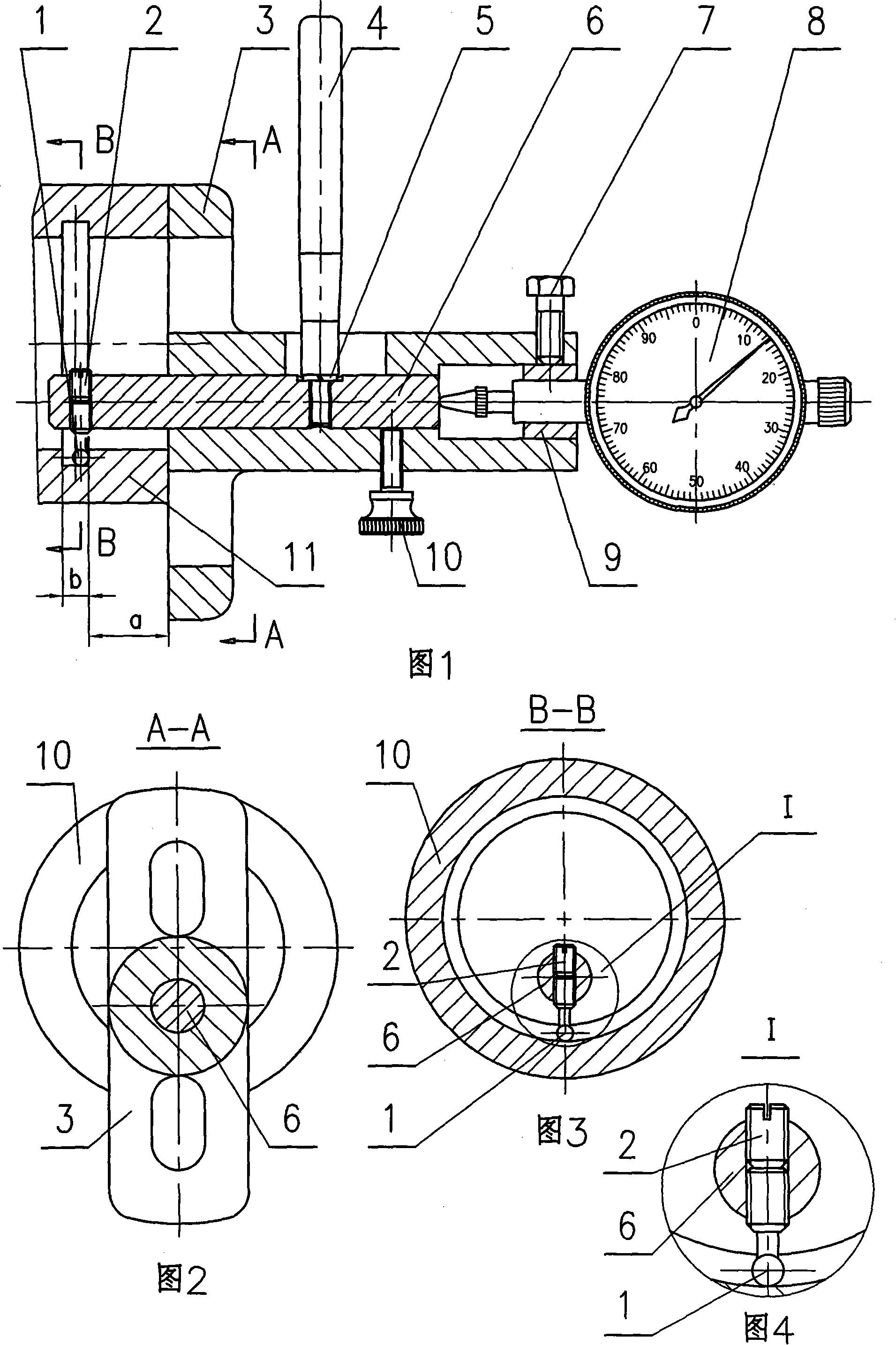

[0013] Referring to accompanying drawing 1, the measuring tool for the axial dimension of the inner hole groove consists of a ball measuring head 1, a screw 2, a measuring body 3, a handle 4, a spring washer 5, a sliding measuring rod 6, a bolt 7, a dial indicator 8, a split sleeve 9 and Composed of 10 knurled head screws. Ball measuring head 1 is contained in one end of sliding measuring rod 6 with screw 2 locking (seeing accompanying drawing 4) in the screw hole perpendicular to and intersecting with sliding measuring rod 6 axis lines with its stud. The sliding measuring rod 6 is installed in the inner hole of the measurement concrete 3 and the fit is H7 / g6, and the large end face of the measuring concrete used for measuring is matched with the sliding measuring rod. The verticality tolerance of the inner hole is 0.01 mm. The handle 4 passes through the axial groove of the concrete 3 and is installed on the sliding measuring rod 6 with the stud at the front end, that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com