Method for manufacturing high-frequency acoustic self-focusing spherical probe

A self-focusing, acoustic technology, applied in the direction of ultrasound therapy, sound wave diagnosis, scientific instruments, etc., to achieve the effect of mass production, smooth surface and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] A method for preparing a high-frequency acoustic self-focusing spherical probe of this embodiment includes the following specific steps:

[0019] 1. Preparation of silicon nitride layer on the substrate

[0020] like figure 1 , based on a high-quality silicon wafer (single crystal orientation (100)), grow a certain thick silicon nitride (SiN) layer on the silicon wafer (thickness can be adjusted as required, such as 1-5 microns, preferably in the present embodiment 1 micron). There are many methods for preparing the silicon nitride layer in this step, such as chemical vapor deposition, ion beam enhanced deposition, magnetron reactive sputtering, etc., and chemical vapor deposition is preferred in this embodiment.

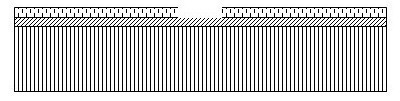

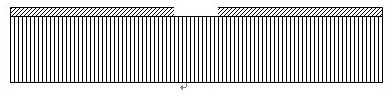

[0021] 2. Perform photolithography treatment on the silicon nitride layer to open several "windows" in the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com