Preparation method of carbon material loaded nano-scale multi-component alloy

A nanoscale, multi-element alloy technology, applied in nanotechnology for materials and surface science, multi-walled carbon nanotubes, nano-carbon, etc., can solve the problem of not being suitable for the preparation of multi-element alloy nanoparticles, which is difficult to meet the requirements of preparation and performance control , Uncontrollable nanoparticle particle size and other problems, to achieve the effect of increasing electrical conductivity and catalytic performance, reducing preparation cost, and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

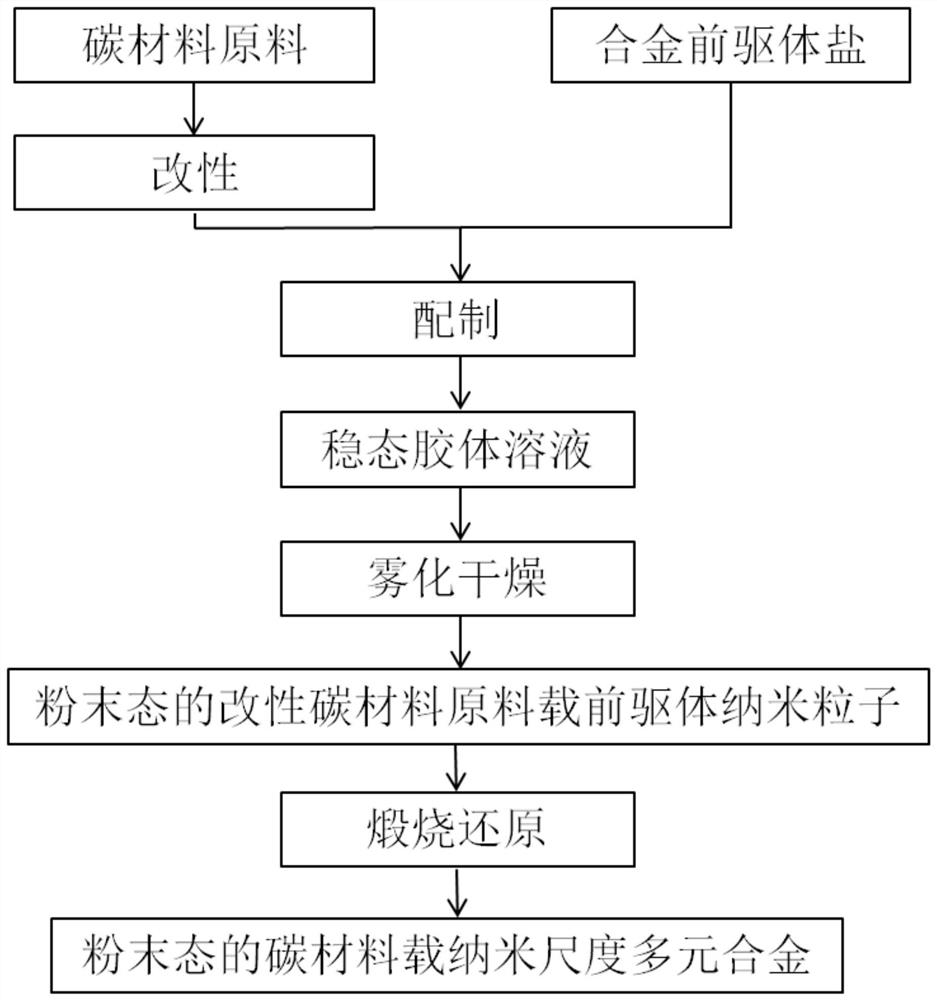

Method used

Image

Examples

Embodiment 1

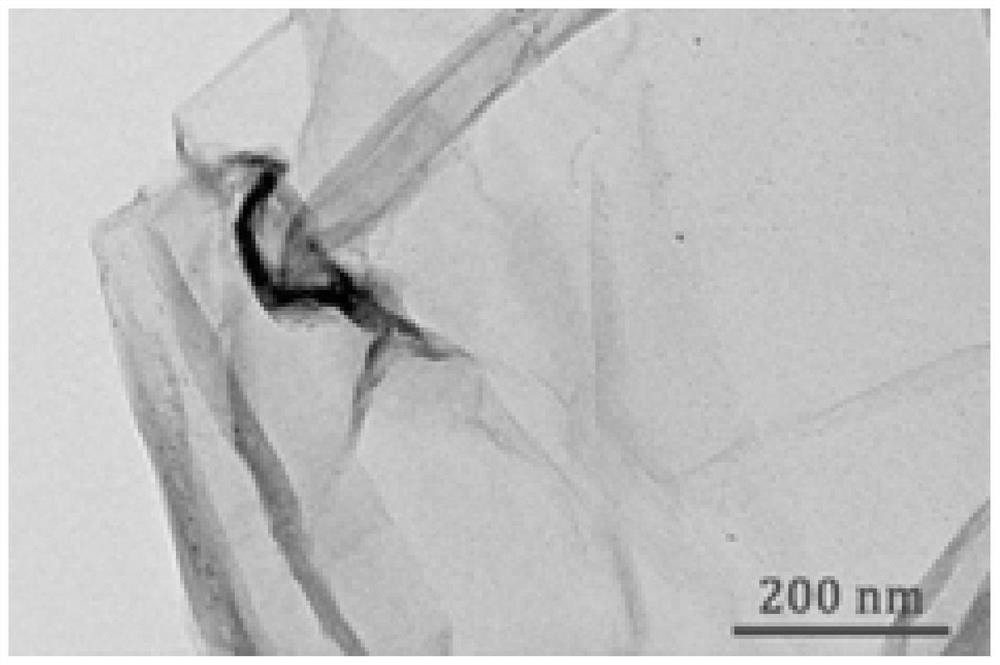

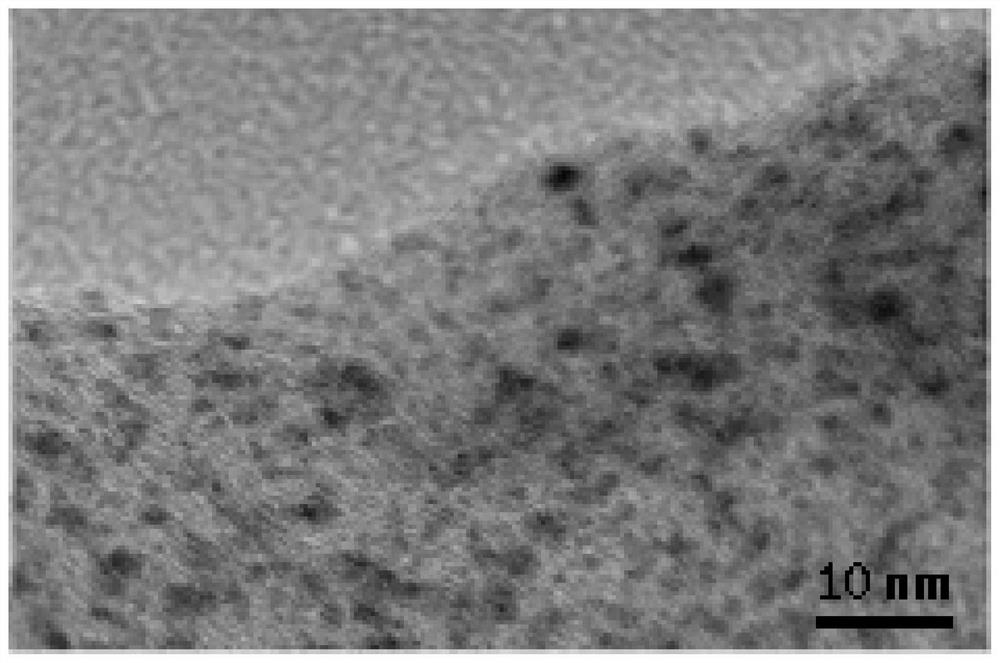

[0048] The carbon material-supported nanoscale multi-element alloy in this implementation is a graphene-supported PtCoCuFeNiRu nanoscale six-element high-entropy alloy, wherein the molar numbers of each metal element are equal.

[0049] Step 1. Prepare the modified carbon material raw material and alloy precursor salt to obtain a stable colloidal solution; the modification process is: add the carbon material raw material to a nitric acid solution with a mass fraction of 70% and soak for 3 hours, The modified carbon material raw material is obtained; the preparation process is: adding the modified carbon material raw material to deionized water and then ultrasonicating for 2 hours to obtain a modified carbon material raw material colloidal solution, and then heating the modified carbon material raw material colloidal solution to 80 After adding the alloy precursor salt and stirring to obtain a stable colloidal solution; the alloy precursor salt is ammonium chloroplatinate, cobal...

Embodiment 2

[0078] The carbon material-supported nanoscale multi-element alloy in this embodiment is a graphene-supported PtCoCuFe nanoscale quaternary alloy, wherein the number of moles of each metal element is equal.

[0079] Step 1. Prepare the carbon material raw material with alloy precursor salt after modification to obtain a stable colloidal solution; the modification process is: add the carbon material raw material to a nitric acid solution with a mass fraction of 80% and soak for 2 hours, The modified carbon material raw material is obtained; the preparation process is: adding the modified carbon material raw material to deionized water and ultrasonicating for 5 hours to obtain a modified carbon material raw material colloidal solution, and then heating the modified carbon material raw material colloidal solution to 85 Add the alloy precursor salt after ℃ and stir to obtain a stable colloidal solution; the alloy precursor salt is ammonium chloroplatinate, cobalt chloride, copper n...

Embodiment 3

[0084] The carbon material-supported nanoscale multi-element alloy in this implementation is a graphene-supported PtCoCuFeNiRuIrRhPdW nanoscale ten-element high-entropy alloy, wherein the number of moles of each metal element is equal.

[0085] Step 1. Prepare the modified carbon material raw material and alloy precursor salt to obtain a stable colloidal solution; the modification process is: add the carbon material raw material to a nitric acid solution with a mass fraction of 65% and soak for 2.5 hours , to obtain a modified carbon material raw material; the process of the preparation is: adding the modified carbon material raw material to deionized water and then ultrasonicating for 3 hours to obtain a modified carbon material raw material colloidal solution, and then heating the modified carbon material raw material colloidal solution to Add the alloy precursor salt after 90°C and stir to obtain a stable colloidal solution; the alloy precursor salt is ammonium chloroplatina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com