PPS (polyphenylene sulfide) flashing equipment and spinning method thereof

A technology of flash spinning and polyphenylene sulfide, applied in the field of non-woven fabrics, can solve the problems of single variety and low output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

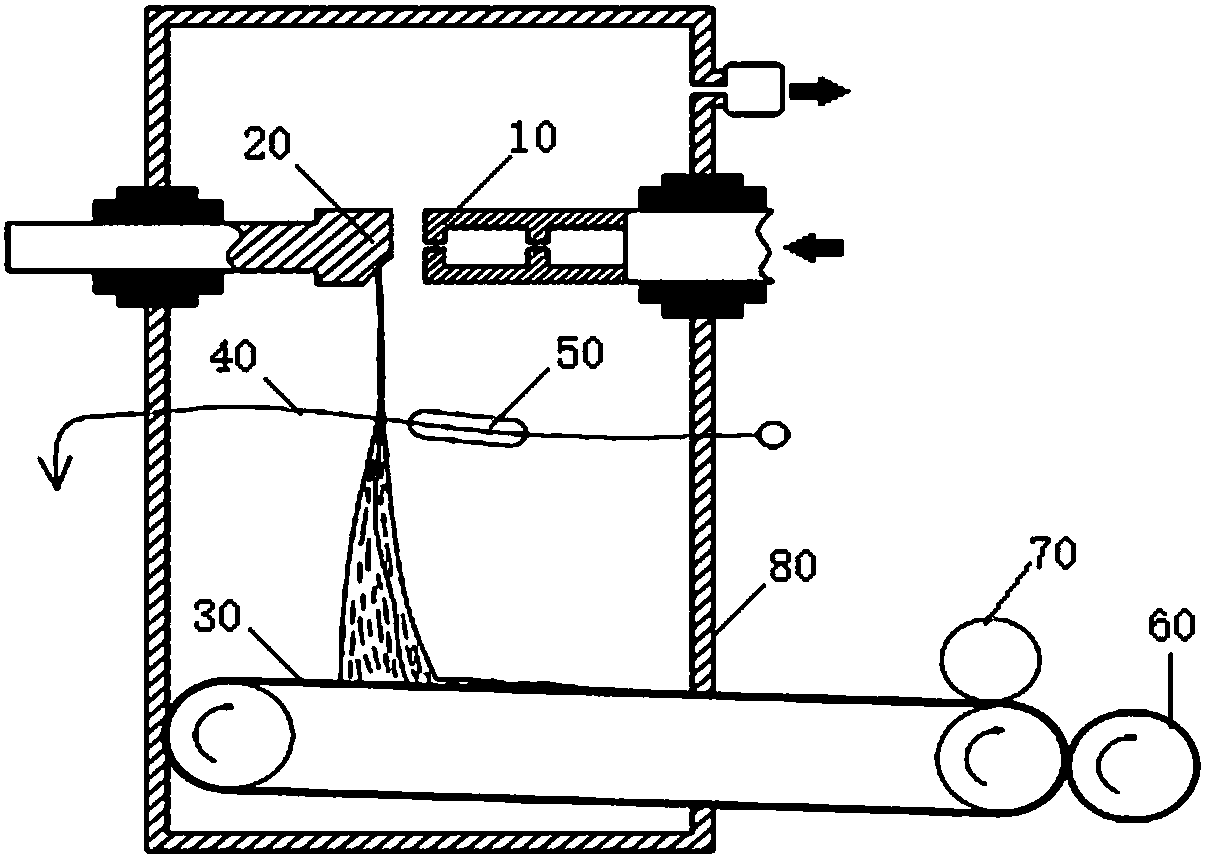

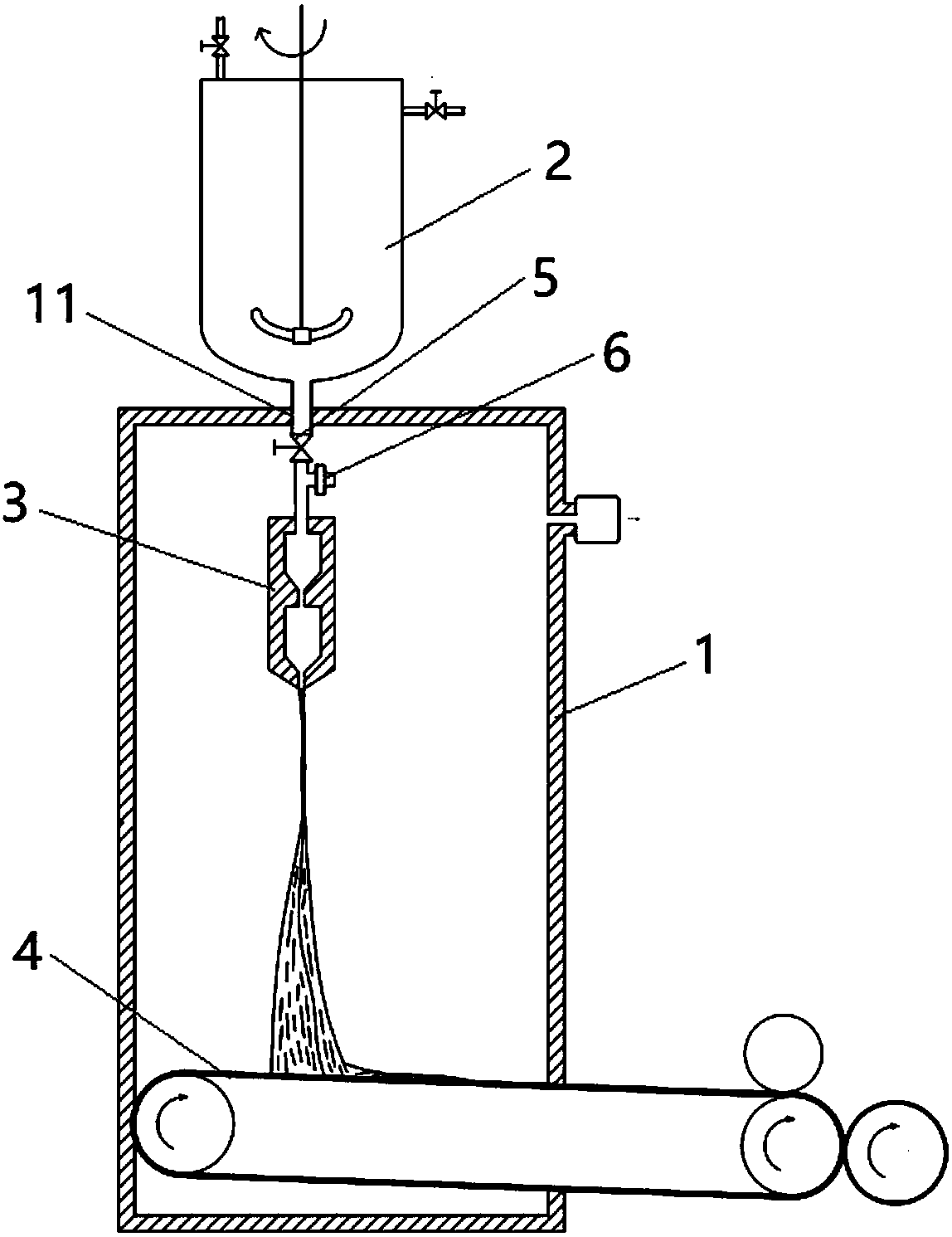

[0023] Such as figure 2 As shown, the present invention discloses a flash spinning equipment for polyphenylene sulfide, including a box body 1, a spinneret 2, a high-pressure reactor 3, and a conveying device 4, and the box body 1 is provided with a spinning The stock solution inlet 11, the spinneret 2 is arranged inside the casing 1, the bottom end of the autoclave 3 is connected with the spinneret 2 through the spinning stock solution inlet 11, and the conveying device 4 is provided At the bottom of the box 1, it also includes a regulating valve 5 for regulating the flow rate of the spinning stock solution and an interceptor 6 for filtering and intercepting impurities, and the regulating valve 5 and the interceptor 6 are sequentially arranged on the spinning Head 2 above.

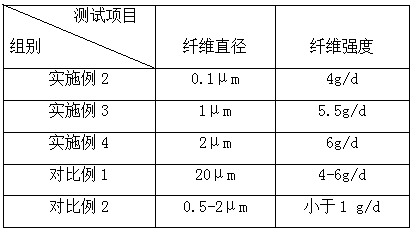

Embodiment 2

[0025] The invention discloses a flash spinning method of polyphenylene sulfide, comprising the following steps:

[0026] Step 1. Preparation of spinning stock solution: adding polyphenylene sulfide and spinning solvent carbon tetrachloride into a high-pressure reactor, fully mixing at a temperature of 250° C. and a pressure of 5 kPa to prepare a spinning stock solution; the high-pressure In the reaction kettle, the stirring speed of the agitator is 80rpm, and the mixing time is 2h. The solid-liquid ratio of polyphenylene sulfide and spinning solvent is 1:40 g / mL.

[0027] Step 2, preparation of polyphenylene sulfide fiber by flash method: the spinning stock solution is ejected from the spinneret of the flash spinning equipment, and the spinning stock solution is ejected from the spinneret of the flash spinning equipment at an air velocity 5000m / min; the solvent of the spinning dope evaporates instantly, the polymer of the spinning dope cools and solidifies rapidly, forming f...

Embodiment 3

[0029] A kind of flash spinning method of polyphenylene sulfide, comprises the following steps:

[0030] Step 1. Preparation of spinning dope: Add polyphenylene sulfide and spinning solvent ethyl chloride to a high-pressure reaction kettle, and fully mix them at a temperature of 300°C and a pressure of 15kPa to prepare a spinning dope; the high-pressure reaction In the kettle, the stirring speed of the agitator is 100rpm, and the mixing time is 5h. The solid-liquid ratio of polyphenylene sulfide and spinning solvent is 10:30 g / mL.

[0031] Step 2, preparation of polyphenylene sulfide fiber by flash method: the spinning stock solution is ejected from the spinneret of the flash spinning equipment, and the spinning stock solution is ejected from the spinneret of the flash spinning equipment at an air velocity 7000m / min; the solvent of the spinning dope evaporates instantly, the polymer in the spinning dope cools and solidifies rapidly, forming fiber bundles, which directly settl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com