Method for forecasting diameter and lateral motion of melt-blown strand

A technology of lateral movement and prediction method, applied in melt spinning, special data processing applications, instruments, etc., can solve problems such as time-consuming, increased production costs, and inability to simulate the lateral movement of filaments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

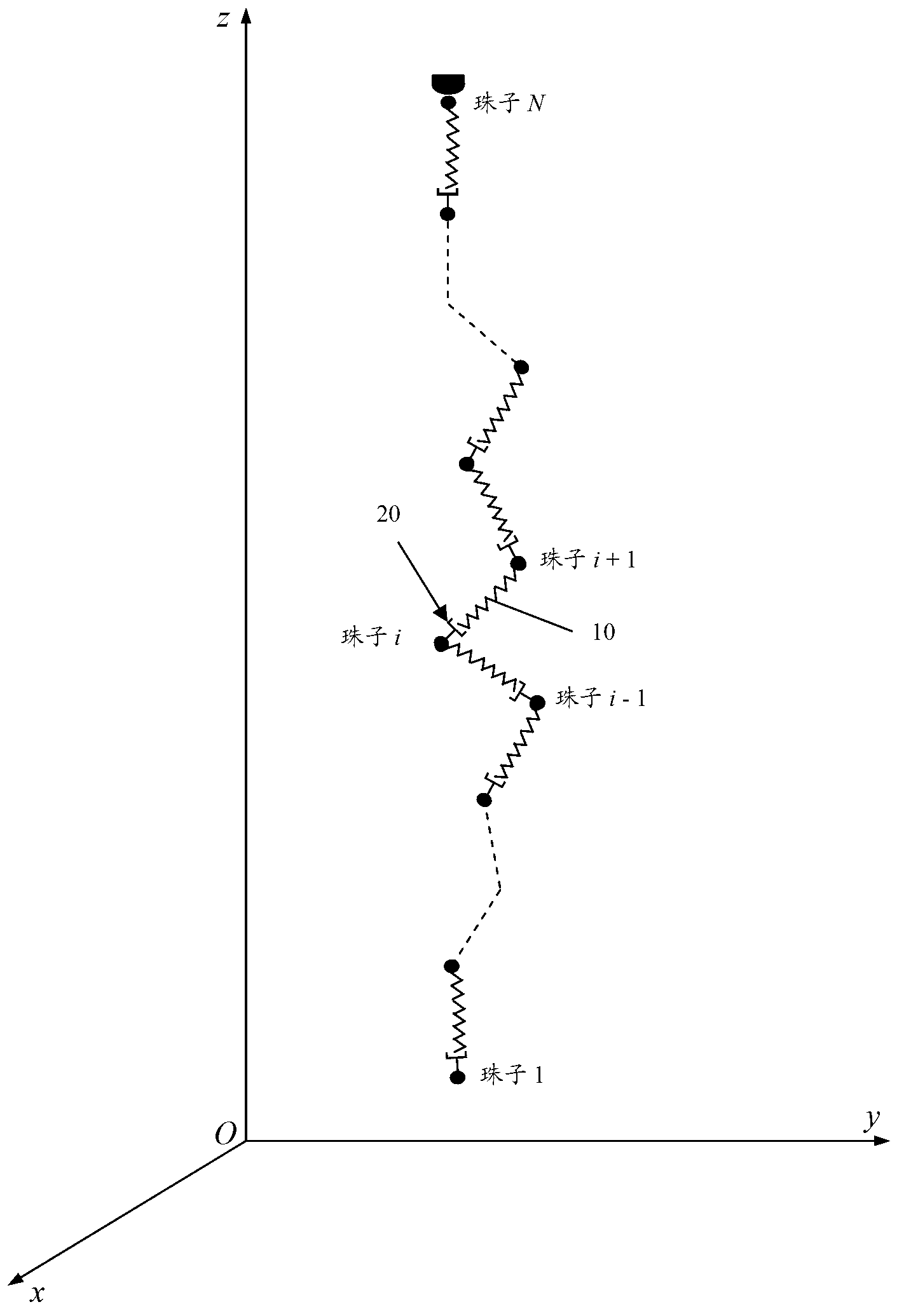

[0145] The steps of the meltblown filament diameter and lateral motion prediction method include:

[0146] (1) Obtain relevant parameters of raw materials, equipment and processes.

[0147] Raw material parameters: The raw material is polypropylene, and its density and constant pressure specific heat are determined by the following formula:

[0148] ρ = 1 1.145 + 0.000903 · θ i C p = 0.3669 + 0.00242 · θ i ...

Embodiment 2

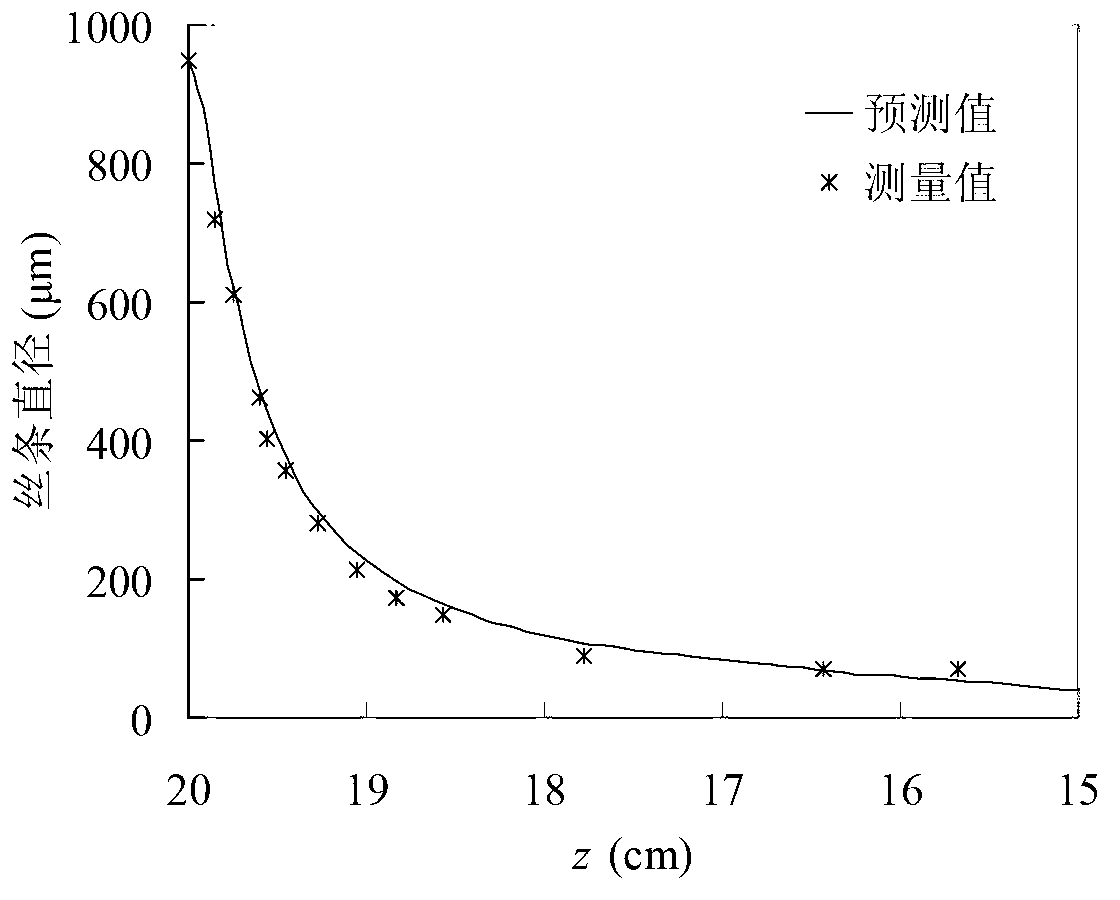

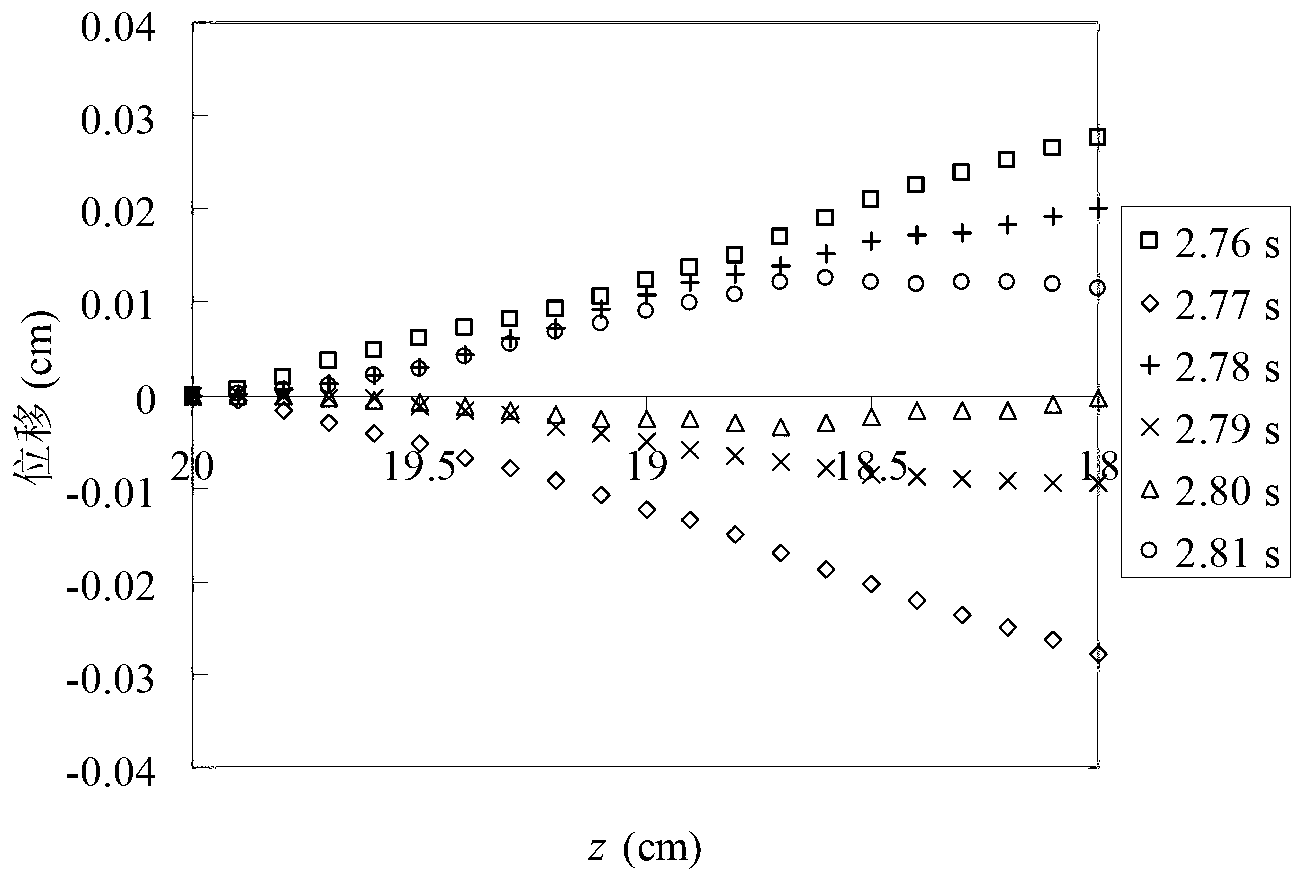

[0159] The steps of the meltblown filament diameter and lateral motion prediction method include:

[0160] (1) Obtain relevant parameters of raw materials, equipment and processes.

[0161] Raw material parameters: The raw material is polypropylene, and its density and specific heat at constant pressure are determined by formula (1). Its shear viscosity is determined by the following formula:

[0162] η = 3.15 × 10 - 4 exp ( 6021 θ i + 273 )

[0163] Equipment parameters: double-slot nozzles are used, and the relevant nozzle parameters are: the airflow angle is 60°, the width of the head end is 2.02mm, the width of the notch is 0.65mm, and the diameter of the spinneret hole is 0.4mm.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com