Microalloying synergistically strengthened graphene titanium-based composite material and preparation method thereof

A titanium-based composite material and micro-alloying technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems that violate the original intention and application, affect the service life and scope of use of titanium-based composite materials, achieve uniform distribution, avoid The effect of spreading the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

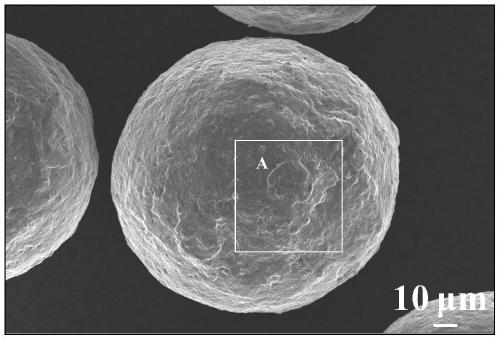

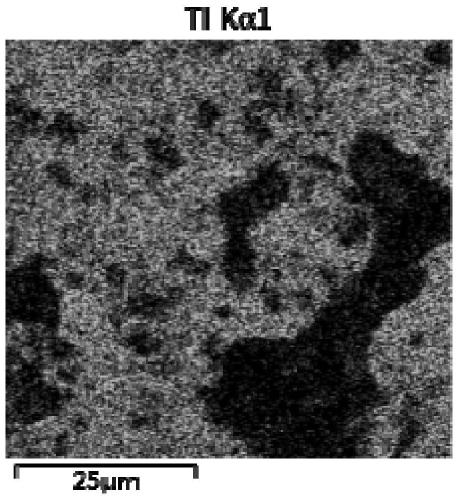

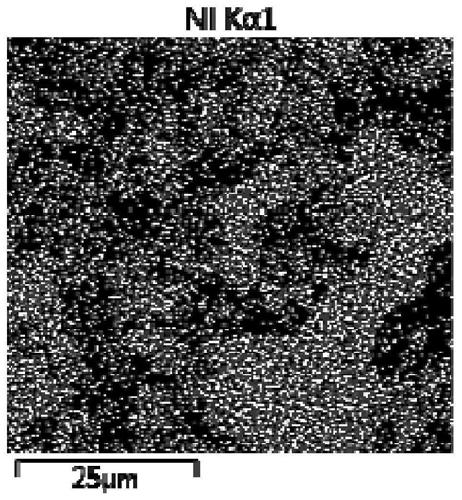

[0038] The micro-alloying synergistically strengthened graphene-titanium-based composite material of this embodiment uses CT20 titanium alloy as the substrate, and the nickel metal for micro-alloying is uniformly coated on the surface of the CT20 titanium alloy substrate in a quasi-continuous manner through physical bonding. Dispersed on the outer surface of CT20 titanium alloy coated with metallic nickel for microalloying, with TiC nanoparticles and Ti 2 The Ni nanoparticles collectively form a quasi-continuous network; the average grain size in the network is 150 μm.

[0039] The preparation method of the microalloying synergistically strengthened graphene-titanium-based composite material of the present embodiment comprises the following steps:

[0040] Step 1. Selection of powder: Select 200g of spherical CT20 titanium alloy powder with a particle size of 80-120 mesh and a sphericity of 0.8 as the matrix powder, and select 4g of flake nickel powder with a particle size of ...

Embodiment 2

[0055] The micro-alloying synergistically strengthened graphene-titanium-based composite material in this embodiment uses CT20 titanium alloy as the substrate, and the metal silver for micro-alloying is uniformly coated on the surface of the CT20 titanium alloy substrate in a quasi-continuous manner through physical bonding. Dispersed on the outer surface of the CT20 titanium alloy matrix coated with metallic silver for microalloying, with TiC nanoparticles and Ti 2 The Ag nanoparticles collectively form a quasi-continuous network; the average grain size in the network is 100 μm.

[0056] The preparation method of the microalloying synergistically strengthened graphene-titanium-based composite material of the present embodiment comprises the following steps:

[0057] Step 1. Selection of powder: Select 200g of spherical CT20 titanium alloy powder with a particle size of 80 mesh to 120 mesh and a sphericity of 0.85 as the matrix powder, and 5g of flake silver powder with a part...

Embodiment 3

[0068] The micro-alloying synergistically strengthened graphene-titanium-based composite material in this embodiment uses CT20 titanium alloy as the substrate, and the metal silver for micro-alloying is uniformly coated on the surface of the CT20 titanium alloy substrate in a quasi-continuous manner through physical bonding. Dispersed on the outer surface of the CT20 titanium alloy matrix coated with metallic silver for microalloying, with TiC nanoparticles and Ti 2 The Ag nanoparticles collectively form a quasi-continuous network; the average grain size in the network is 120 μm.

[0069] The preparation method of the microalloying synergistically strengthened graphene-titanium-based composite material of the present embodiment comprises the following steps:

[0070] Step 1. Selection of powder: Select 200g of spherical CT20 titanium alloy powder with a particle size of 100 mesh to 150 mesh and a sphericity of 0.85 as the base powder, and 2g of flake silver powder with a parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com