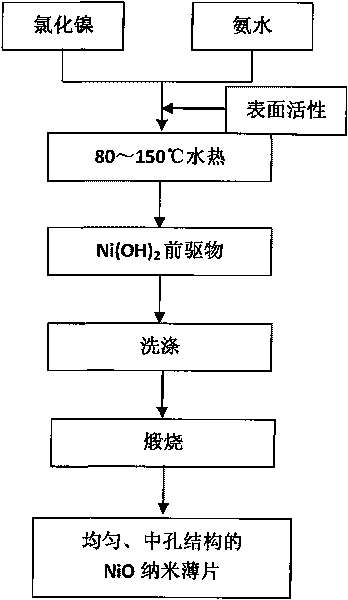

Preparation method of nickel oxide nano flake with uniform and mesoporous structure

A nanosheet, nickel oxide technology, applied in nanostructure manufacturing, nickel oxide/nickel hydroxide, nanotechnology, etc., to achieve uniform distribution of holes, low equipment requirements, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Put 80mL, 0.05mol / L aqueous solution of nickel chloride hexahydrate into a 100mL beaker, add 0.5g cetyl ammonium bromide (CTAB), and stir magnetically for 3 hours; add 0.8mL ammonia water dropwise , magnetically stirred for 2 hours to form a light green transparent mixed solution;

[0033] (2) Place the mixed solution obtained in step (1) in a polytetrafluoroethylene-lined stainless steel reactor, seal it, and heat it in a muffle furnace for 15 hours; the reaction temperature is 150°C;

[0034] (3) filtering, washing and drying the turbid solution obtained in step (2) to obtain a nickel hydroxide precursor;

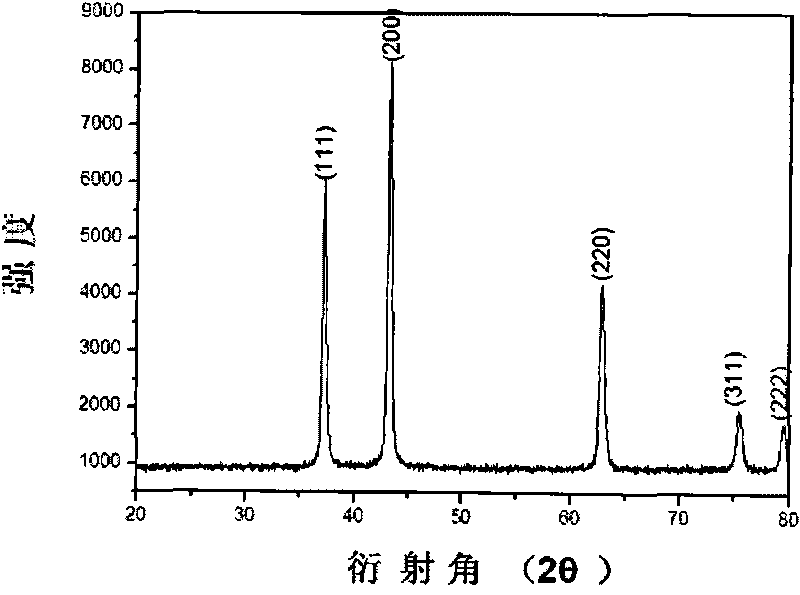

[0035] (4) The nickel hydroxide precursor obtained in step (3) was calcined at 500 °C for 2 h to obtain uniform and mesoporous NiO nanoflakes. figure 2 The X-ray diffraction pattern of NiO nanoflakes with mesoporous structure, all the diffraction peaks correspond to the cubic phase NiO, and the diffraction peak intensity is high and sharp, indicating that the...

Embodiment 2

[0037] (1) Put 80mL, 0.75mol / L aqueous solution of nickel chloride hexahydrate into a 100mL beaker, add 0.5g polyvinylpyrrolidone (PVP), and stir magnetically for 3 hours; add 0.8mL ammonia water dropwise, and stir magnetically for 2h , forming a light green transparent mixed solution;

[0038] (2) Place the mixed solution obtained in step (1) in a polytetrafluoroethylene-lined stainless steel reactor, seal it, and heat it in a muffle furnace for 18 hours; the reaction temperature is 120°C;

[0039] (3) filtering, washing and drying the turbid solution obtained in step (2) to obtain a nickel hydroxide precursor;

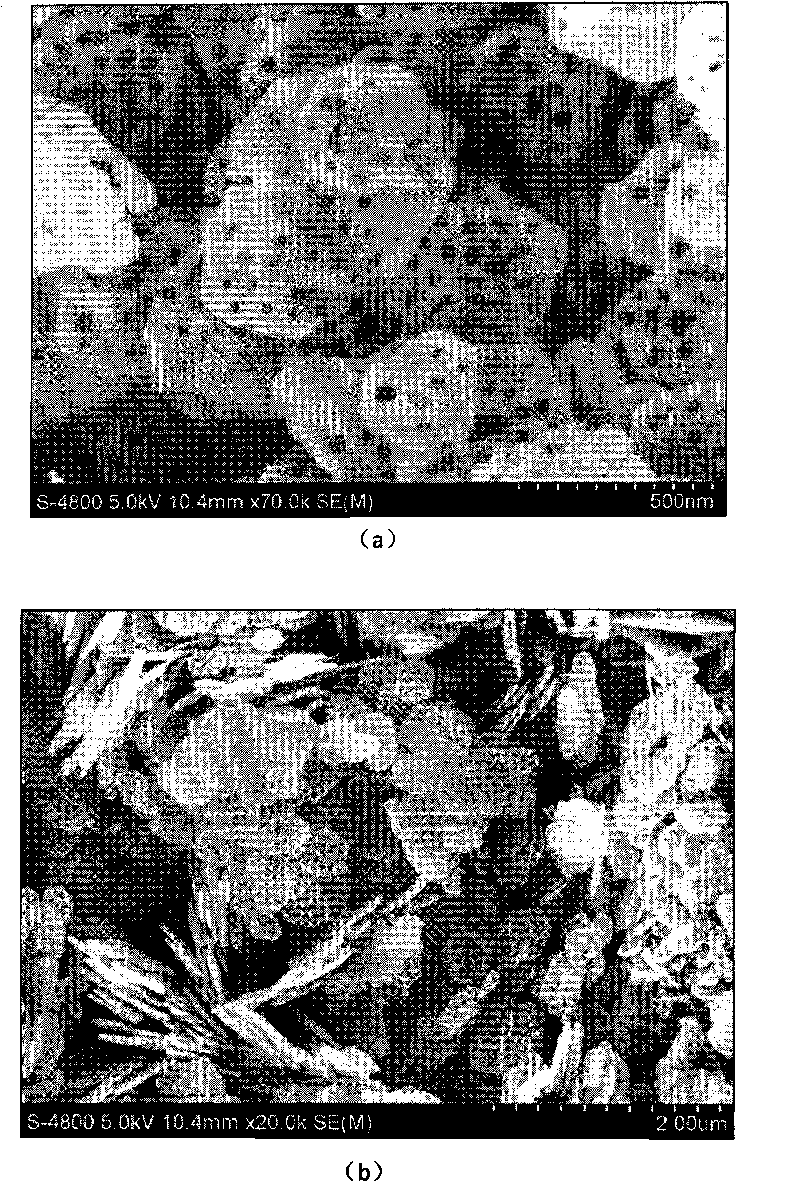

[0040] (4) Calcining the nickel hydroxide precursor obtained in step (3) at 400° C. for 3 h to obtain NiO nanoflakes with uniform and mesoporous structure. image 3 The scanning electron microscope spectrum of NiO nanosheets with mesoporous structure, the mesopore distribution of NiO nanosheets is uniform, and the diameter of the holes is 30-40nm; the diameter of Ni...

Embodiment 3

[0042] (1) Put 80mL, 0.15mol / L aqueous solution of nickel nitrate hexahydrate into a 100mL beaker, add 0.7g of polyvinylpyrrolidone (PVP), and stir magnetically for 3h; add 1.0mL ammonia water dropwise, stir magnetically for 2h, Form a light green transparent mixed solution;

[0043] (2) Place the mixed solution obtained in step (1) in a polytetrafluoroethylene-lined stainless steel reactor, seal it, and heat it in a muffle furnace for 20 hours; the reaction temperature is 80°C;

[0044] (3) filtering, washing and drying the turbid solution obtained in step (2) to obtain a nickel hydroxide precursor;

[0045] (4) Calcining the nickel hydroxide precursor obtained in step (3) at 350° C. for 4 h to obtain NiO nanoflakes with uniform and mesoporous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com