Carbon plasm for electrode of dye sensitization solar battery pair and its making method

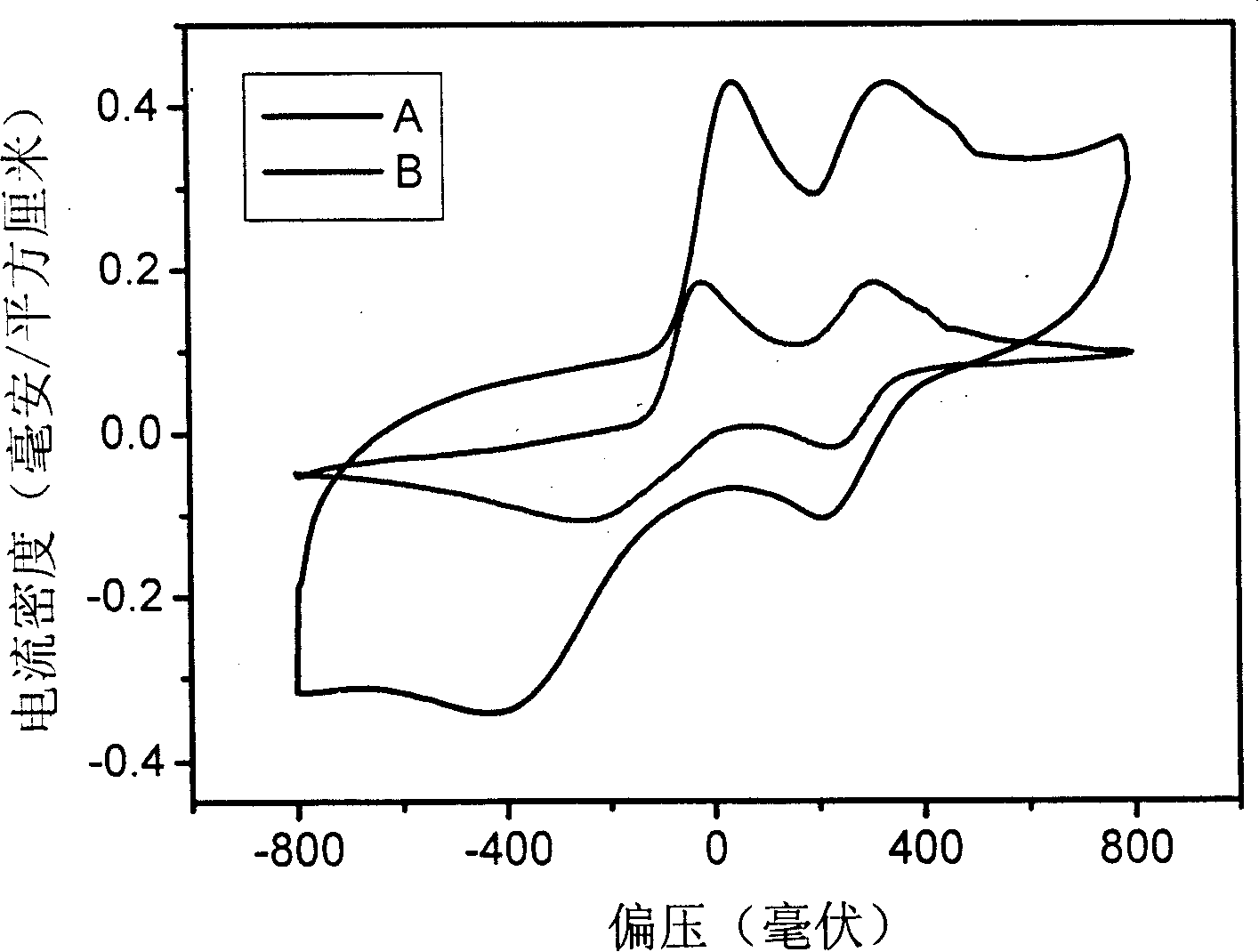

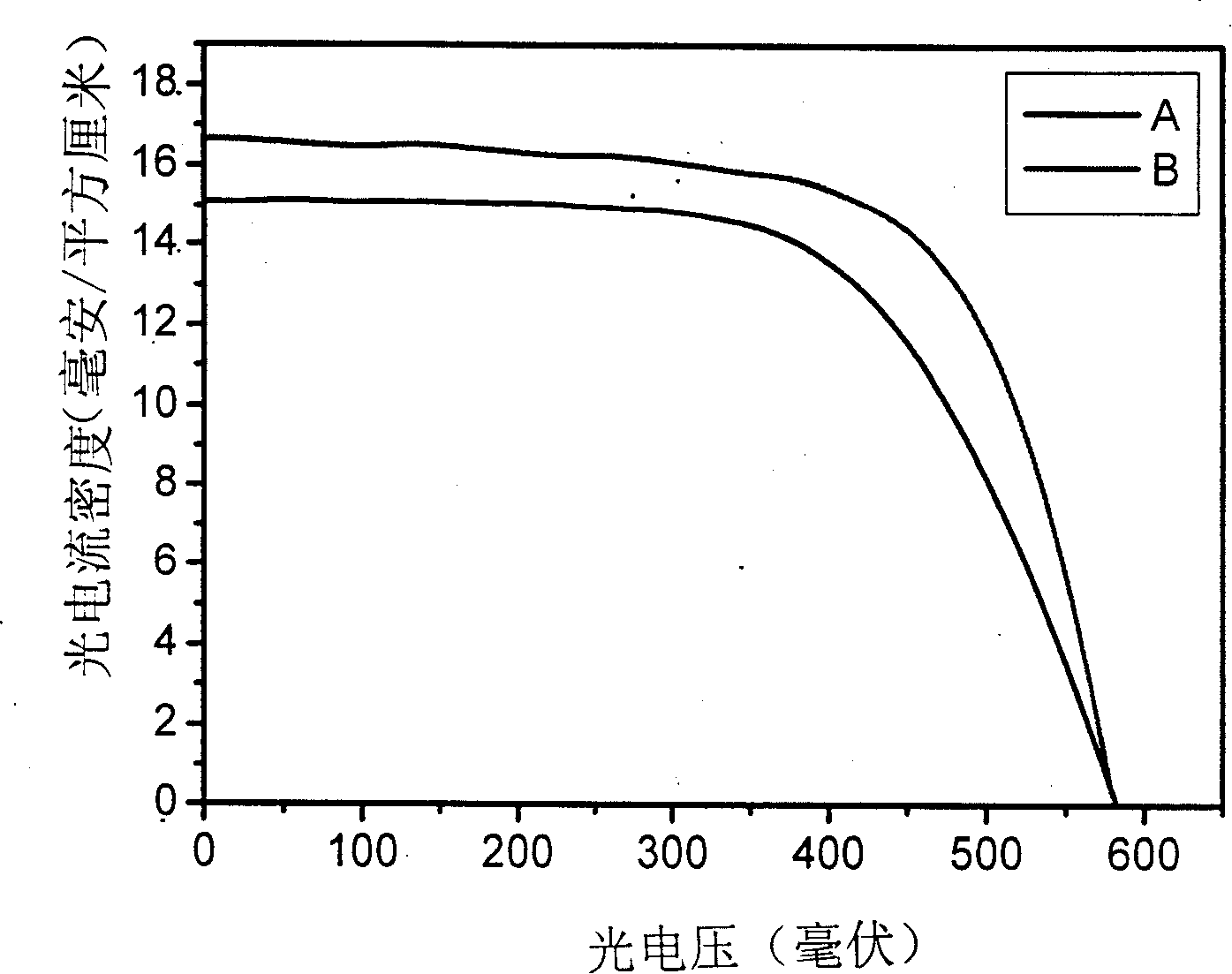

A technology of solar cells and dye sensitization, applied in the field of electrodes, can solve the problems of unfavorable large-scale promotion and application, complex production process, high electrode cost, and achieve good short-circuit current and photoelectric conversion efficiency, uniform distribution of holes, and material cost. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

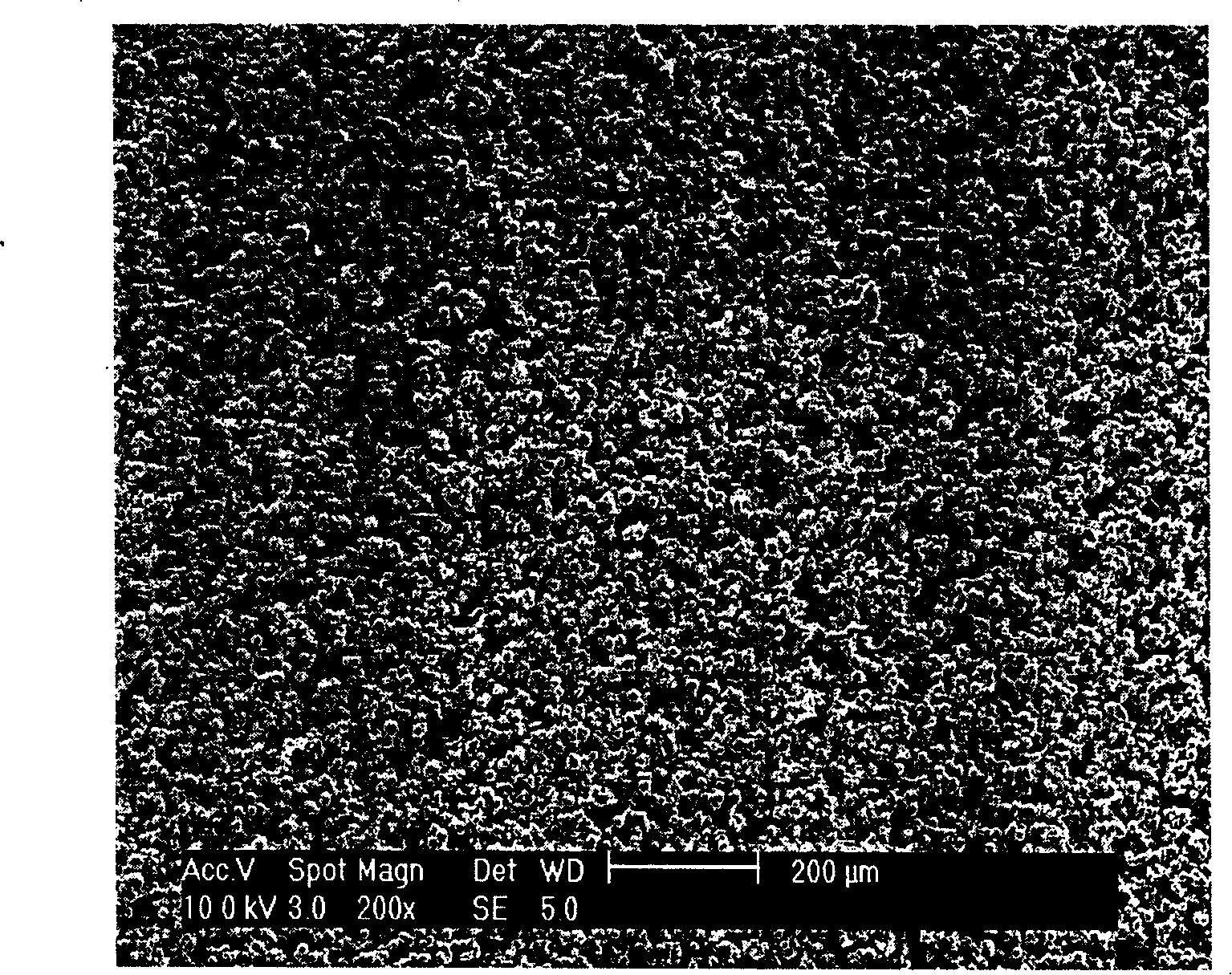

[0044]1. First, prepare hard carbon powder according to the synthesis method described in Example 4 in the patent publication number CN1191195C, and then use a ball mill or other crushing and grinding equipment to grind the hard carbon powder to obtain The particle size is about 6μm, and the specific surface area is 400m 2 / g hard carbon powder, weigh 6.000g hard carbon powder for use;

[0045] 2. Configure the liquid mixture, weigh according to the following components and formula:

[0046] (a) Ethyl cellulose (viscosity modifier) 0.2000g

[0047] (b) Isopropanol (solvent) 15ml;

[0048] 3. Dissolve the weighed ethyl cellulose in isopropanol, and perform mechanical stirring to mix evenly. The mechanical stirring time is 5 minutes, and the temperature is kept at 20-30°C to form a transparent liquid mixture;

[0049] 4. Mix the liquid mixture prepared above with 6.000 g of hard carbon powder, and mix with a ball mill for 4 hours to prepare a carbon slurry.

Embodiment 2

[0051] Weigh 0.2000 g of ethyl cellulose (viscosity modifier), add it to 15 ml of isopropanol (solvent), keep the temperature at 20-30°C, stir for 30 minutes to dissolve. Then 0.5000 g of Triton 100 was added and mixed uniformly to prepare a liquid mixture. Other conditions and steps were the same as in Example 1, to prepare a carbon slurry.

Embodiment 3

[0053] Weigh 0.2500g of ethyl cellulose (viscosity modifier), add it to 15ml of isopropanol (solvent), keep the temperature at 20-30℃, stir for 1 hour to dissolve, and then add 0.5000g of surfactant Triton100 , 5.000g of pore-forming material polyethylene glycol 600 and 0.1000 binder tin dioxide are mixed uniformly, as a liquid mixture. Other conditions and steps were the same as in Example 1, to prepare a carbon slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com