Low porosity closed cell foam aluminum alloy and its preparation method

A closed-cell foam and aluminum alloy technology, which is applied in the field of low-porosity closed-cell foam aluminum alloy and its preparation, can solve the problems that high-porosity foam aluminum alloy cannot meet the requirements, and achieve easy control of the process, high efficiency, and finished products The effect of rate increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 A preparation method for manufacturing low-porosity closed-cell aluminum alloys, comprising the following steps:

[0024] The first step is to heat the aluminum-copper alloy containing 3.5-5.5% copper until it melts;

[0025] In the second step, add a tackifier accounting for 0.5 to 5% (for example, 1.5%) of the weight of the aluminum alloy to stir the aluminum alloy at a speed of 200 to 500 rpm (preferably 400 rpm) to increase the viscosity for 8 minutes to 15 minutes. Minutes (preferably 10 minutes), tackifier can be Ca, aluminum oxide powder, manganese dioxide powder;

[0026] The third step is to add a foaming agent accounting for 0.2-5.0% of the mass of the aluminum alloy and stir at 600-900 rpm (900 rpm is optional) for 40-60 seconds, wherein the foaming agent can be titanium hydride, pozzolan , Calcium carbonate, the addition of foaming agent can be 0.2%, 0.25%, 0.3%, 0.35%, 0.4%, 0.5%, 0.6%, 0.7%, 0.8%, 1.0%, 1.5%, 2.0%, 2.5% , 3.0%, 4.0%, 5.0%; ...

Embodiment 2

[0030] Embodiment 2 A preparation method for manufacturing low-porosity closed-cell aluminum alloys, comprising the following steps:

[0031] The first step is to heat the aluminum-copper alloy containing 3.5-5.5% copper until it melts;

[0032] In the second step, adding tackifier calcium accounting for 0.5-5% (for example, 1.5%) of the weight of the aluminum alloy is used to stir the aluminum alloy at a speed of 200-500 revolutions / minute (preferably 400 revolutions / minute) to increase viscosity for 8 minutes~ 15 minutes (preferably 10 minutes);

[0033] In the third step, add foaming agent titanium hydride accounting for 0.2-2.0% of the mass of the aluminum alloy and stir at 600-900 rpm (for example, 900 rpm) for 40-60 seconds, wherein the amount of foaming agent added can be 0.2 %, 0.25%, 0.3%, 0.35%, 0.4%, 0.5%, 0.6%, 0.7%, 0.8%, 1.0%, 1.5%, 2.0%;

[0034] The fourth step is to stir again at a speed of 1000 rpm to 2000 rpm for 10s to 180s. The stirring speed can be sele...

Embodiment 3

[0036] In the sixth step, the heat-preserved foamed aluminum alloy melt is simultaneously cooled in all directions to obtain a closed-cell foamed aluminum alloy. Embodiment 3 A preparation method for manufacturing low-porosity closed-cell aluminum alloys, comprising the following steps:

[0037] The first step is to heat the aluminum-copper alloy containing 3.5-5.5% copper until it melts;

[0038]In the second step, adding tackifier calcium accounting for 0.5-5% (for example, 1.5%) of the weight of the aluminum alloy is used to stir the aluminum alloy at a speed of 200-500 revolutions / minute (preferably 400 revolutions / minute) to increase viscosity for 8 minutes~ 15 minutes (preferably 10 minutes);

[0039] In the third step, add foaming agent titanium hydride accounting for 0.2 to 5.0% of the mass of the aluminum alloy and stir at 600 to 900 rpm (900 rpm is optional) for 40 to 60 seconds, wherein the amount of foaming agent added can be 0.2%, 0.25%, 0.3%, 0.35%, 0.4%, 0.5%,...

PUM

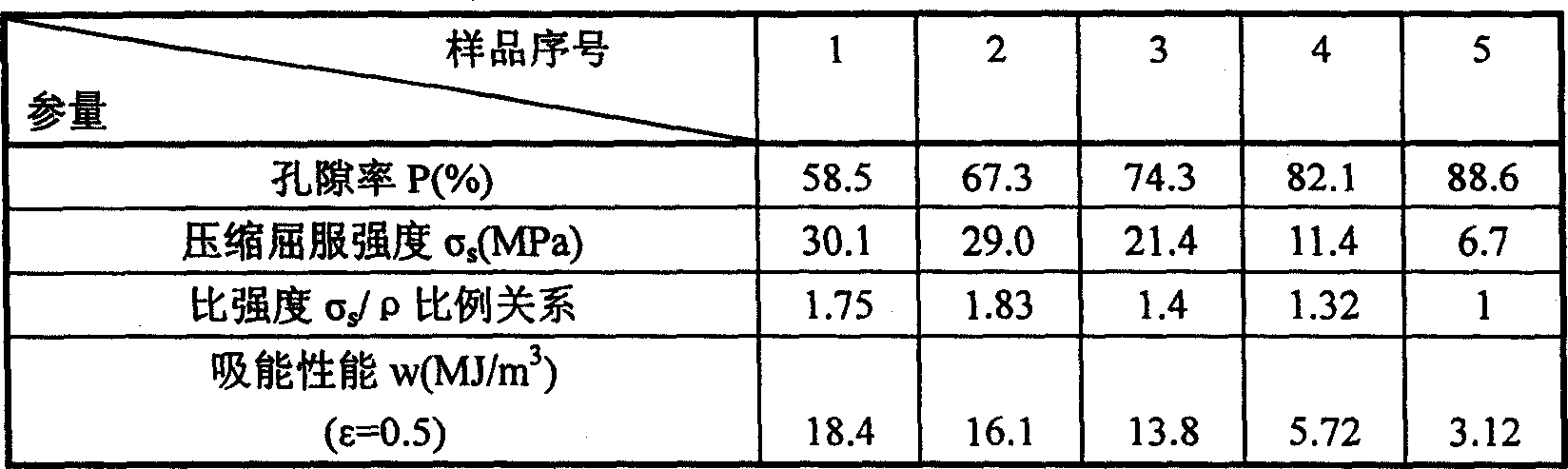

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com