Electrostatic spinning porous carbon material and preparation method thereof

A porous carbon material, electrospinning technology, applied in filament/thread forming, textile and papermaking, heating/cooling fabrics, etc., can solve the problems affecting nitrogen doping content, stability, and material properties, etc., to achieve preparation The process is easy to control, the pore structure is improved, and the process flow is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

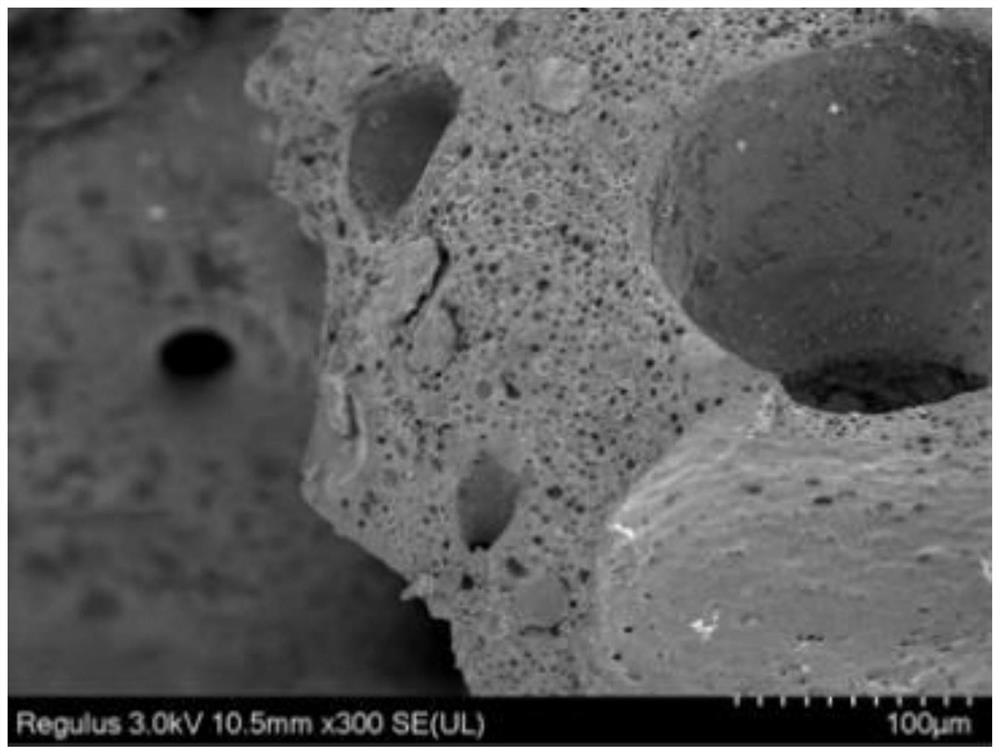

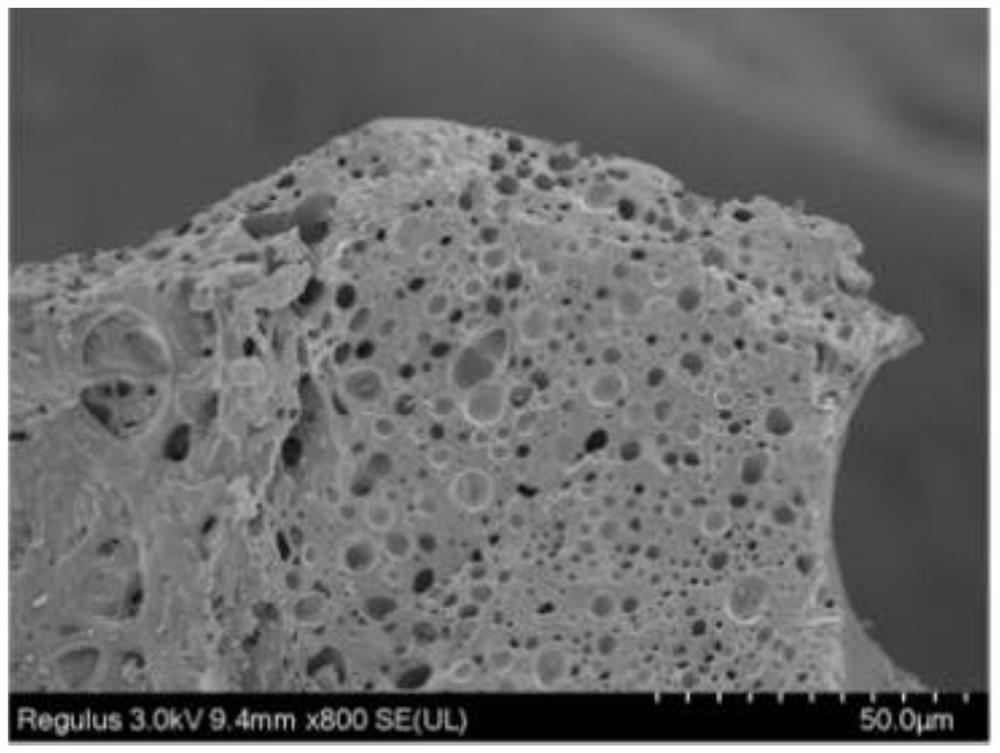

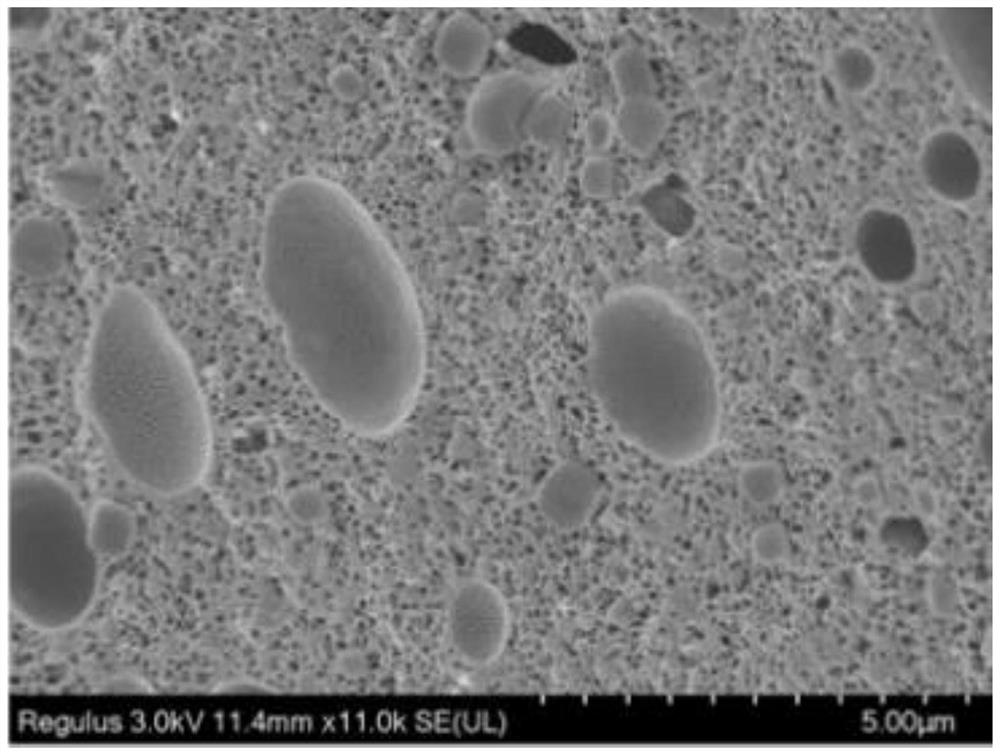

[0042] The preparation method of electrospun porous carbon material in embodiment 1-5 comprises the following steps:

[0043] In terms of percentage by weight, 6.7% of silk fibroin, 1.3% of polyethylene oxide, 2% of potassium chloride and 90% of formic acid are uniformly mixed to obtain a spinning solution. Among them, the molar mass of polyethylene oxide is 600,000.

[0044] The spinning solution was drawn into a 10 mL disposable syringe, and electrospun to obtain an electrospun membrane.

[0045] The electrospun membrane was placed in a corundum boat and subjected to high-temperature carbonization treatment in a nitrogen atmosphere to obtain an electrospun porous carbon material sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com