Method for continuously extracting beta-methylnaphthalene crude product from methylnaphthalene enrichment liquor

A technology for methylnaphthalene enriched liquid and crude methylnaphthalene, applied in separation methods, chemical instruments and methods, solution crystallization, etc., can solve problems such as increasing separation difficulty and affecting the purity and yield of β-methylnaphthalene, Achieve the effects of good removability, increased thickness and hardness, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

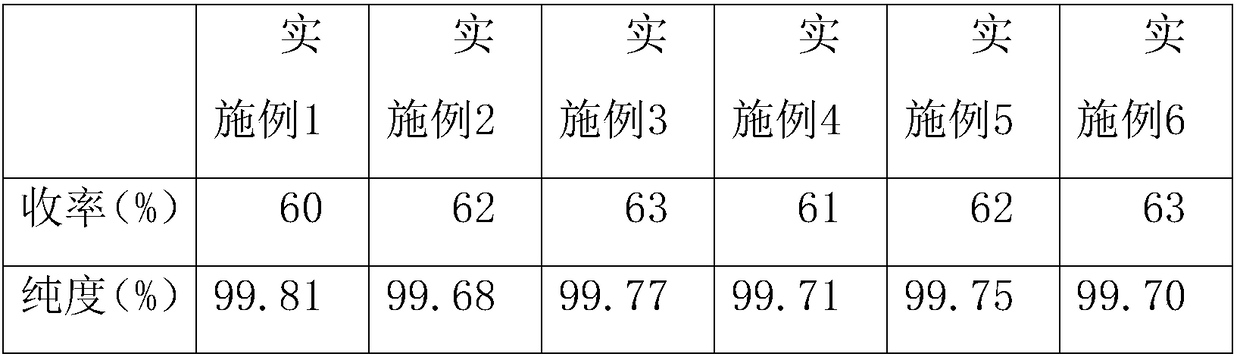

Examples

Embodiment 1

[0026] (1) After cleaning the aluminum sheet with acetone and deionized water ultrasonically for 15 minutes at a power of 250W, place it in an electrolyte solution of ethanol and perchloric acid with a volume ratio of 4:1, at a voltage of 15v, at 4 °C, electrochemically polished for 2 min to obtain a pretreated aluminum sheet.

[0027] (2) The pretreated aluminum sheet is used as the anode, the graphite plate is the cathode, and the 0.5moL / L sulfuric acid solution containing 0.3g / L cerium salt or molybdate is used as the electrolyte, at 100V, at 0.1°C, Carry out an anodic oxidation for 3-6 hours, take out the aluminum oxide film that has been oxidized once, and soak it in the mixed solution of phosphoric acid and chromic acid. The soaking process is as follows: the first stage, soak in the mixed solution at a temperature of 30°C for 20 minutes; In the second stage, heat the mixed solution to 60°C at a speed of 4°C / min, and keep soaking for 120 minutes; in the third stage, stop...

Embodiment 2

[0032] (1) After cleaning the aluminum sheet with acetone and deionized water ultrasonically for 30 minutes at a power of 300W, place it in the electrolyte solution of ethanol and perchloric acid with a volume ratio of 4:1, and at a voltage of 20v, at 4 °C, electrochemically polished for 4 minutes to obtain a pretreated aluminum sheet.

[0033] (2) The pretreated aluminum sheet is used as the anode, the graphite plate is the cathode, and the 0.8moL / L sulfuric acid solution containing 0.5g / L cerium salt or molybdate is used as the electrolyte, at 150V, at 1°C, Carry out an anodic oxidation for 6 hours, take out the aluminum oxide film that has been oxidized once, and soak it in the mixed solution of phosphoric acid and chromic acid. stage, heat the mixed solution to 80°C at a speed of 6°C / min, and keep soaking for 160 minutes; in the third stage, stop heating, cool the mixed solution to 20°C at a speed of 10°C / hour, and continue soaking for 80 minutes, Remove the acidic soluti...

Embodiment 3

[0038] (1) After cleaning the aluminum sheet with acetone and deionized water ultrasonically for 20 minutes at a power of 280W, it is placed in an electrolyte solution of ethanol and perchloric acid with a volume ratio of 4:1, at a voltage of 18v, at 4 °C, electrochemically polished for 3 minutes to obtain a pretreated aluminum sheet.

[0039] (2) The pretreated aluminum sheet is used as the anode, the graphite plate is the cathode, and the 0.6moL / L sulfuric acid solution containing 0.4g / L cerium salt or molybdate is used as the electrolyte, at 120V, at 0.5°C, Carry out an anodic oxidation for 4 hours, take out the aluminum oxide film that has been oxidized once, and soak it in the mixed solution of phosphoric acid and chromic acid. stage, heat the mixed solution to 70°C at a rate of 5°C / min, and keep soaking for 150 minutes; in the third stage, stop heating, cool the mixed solution to 18°C at a rate of 9°C / hour, and continue soaking for 70 minutes. Remove the acidic soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com