Method for preparing macroscopic through-type porous metal material and continuous casting device thereof

A porous metal, straight-through technology, applied in the field of the preparation of porous metal materials, can solve the problems of difficult to achieve effective control of metal solidification process, discount of the performance advantages of porous metal materials, unsatisfactory porous metal material process, etc. Easy to operate, large aspect ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

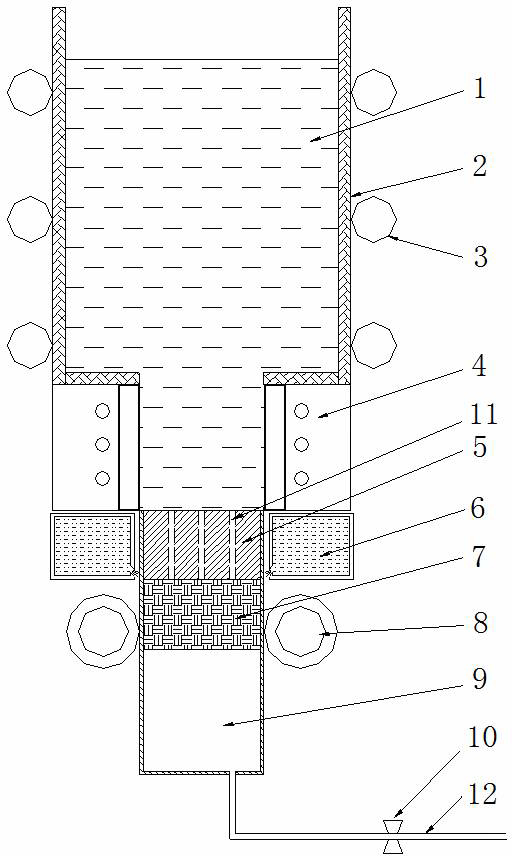

[0030] A method for preparing a macroscopic through-type porous metal material, comprising the steps of:

[0031] a. Heating the liquid metal in the crucible and keeping it warm;

[0032] b. The liquid metal in the crucible is injected downward into the heating crystallizer through the nozzle at the bottom of the crucible, so that the temperature of the liquid metal in the heating crystallizer is kept above the liquidus line;

[0033] c. Blow gas from the bottom of the heated crystallizer to the inner bottom of the liquid metal melt through the template with holes, and at the same time establish a temperature gradient from top to bottom in the liquid metal melt near the dummy rod in the crystallizer;

[0034] d. Through the pull-down of the dummy rod and the back displacement movement of the mold relative to the upward movement of the dummy rod, the casting is pulled up and down in the casting direction of continuous casting, so that the liquid metal passing through the botto...

Embodiment 2

[0046] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

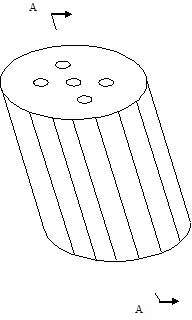

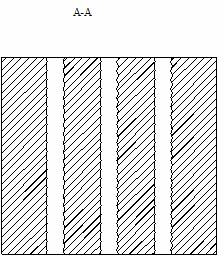

[0047] In this embodiment, the continuous casting device of the present invention can be used to prepare macroscopic straight-through porous Wood's alloy. The crucible 2 can contain liquid Wood's alloy. The bottom of the crucible is a prepared template 5 with five holes evenly distributed. The template 5 The size is Ф20mm×10mm, the template 5 is made of metal copper, and the template is machined to form a through hole 11 with an inner diameter of 1mm, and the template 5 is in direct contact with the liquid metal 1. In the initial continuous casting stage, the dummy rod composed of the template 5, the air brick 7 and the air chamber 9 is inserted into the inner part of the crystallizer 4 by about 20mm, and the crucible 2 is started to be heated, so that the temperature of the Wood alloy metal melt reaches 100°C and crystallization The temperature of the Wood...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com