Manufacturing method of porous tasty bean curd based on microwave pretreatment

A production method and microwave treatment technology, applied in dairy products, cheese substitutes, applications, etc., can solve the problems of uneven pore size, poor flavor, poor yield and elasticity, and achieve improved uniformity, uniform distribution of holes, Excellent yield and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

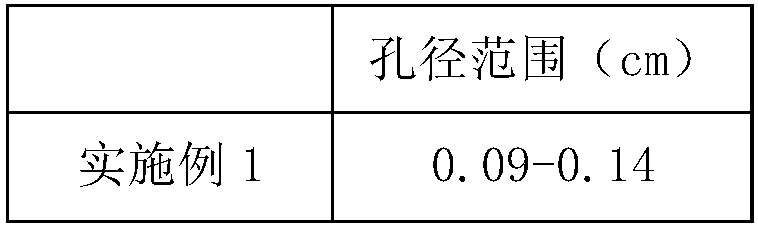

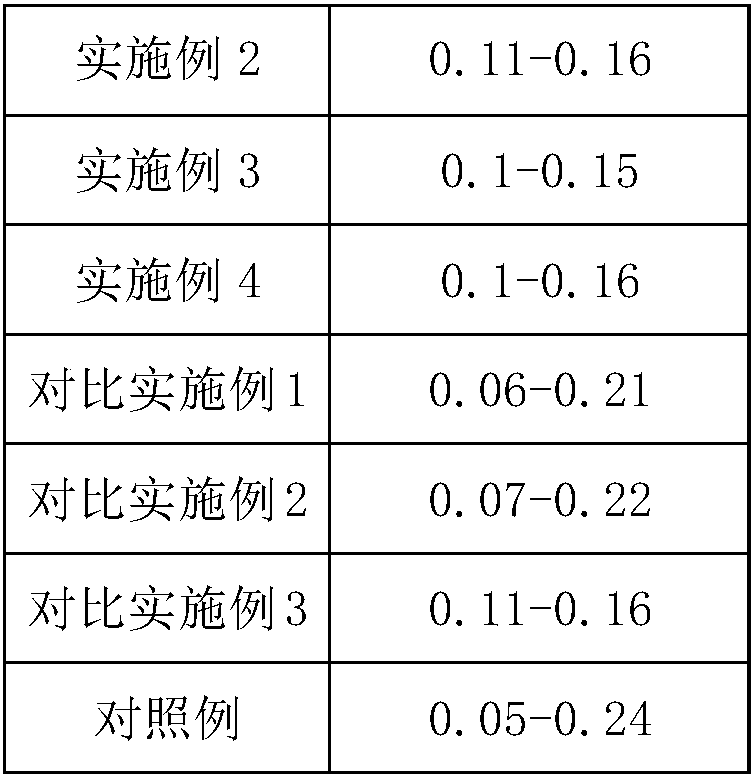

Embodiment 1

[0025] Follow the steps below to make porous tofu:

[0026] (1) Wash and drain the fresh soybeans. The soybeans are composed of Anhui soybeans and Northeast soybeans with a weight ratio of 1:1.2. Add 6 times the weight of distilled water, transfer to a microwave oven for 3 minutes at 200W power, and take out After being cooled to room temperature, pretreated soybeans are obtained;

[0027] (2) Soak the pretreated soybeans obtained in step (1) in water until flat pits appear in the middle of the watercress of the pretreated soybeans, and obtain soaked soybeans after taking them out;

[0028] (3) add water to the soaked soybeans obtained in step (2) and grind to obtain raw soymilk. The Baume degree of the raw soymilk is 10 degrees. The raw soymilk is boiled in an open way for 3 minutes to obtain cooked soymilk, and then immediately add water to cool down. Cool down to 67°C within 12 seconds to obtain a slurry;

[0029] (4) coagulant is added in the slurry that step (3) obtains...

Embodiment 2

[0033] Follow the steps below to make porous tofu:

[0034] (1) Wash and drain the fresh soybeans. The soybeans are composed of Anhui soybeans and Northeast soybeans with a weight ratio of 1:1.2. Add 6 times the weight of distilled water, transfer to a microwave oven for 3 minutes at 200W power, and take out After being cooled to room temperature, pretreated soybeans are obtained;

[0035] (2) Soak the pretreated soybeans obtained in step (1) in water until flat pits appear in the middle of the watercress of the pretreated soybeans, and obtain soaked soybeans after taking them out;

[0036] (3) add water to the soaked soybeans obtained in step (2) and grind to obtain raw soymilk. The Baume degree of the raw soymilk is 11 degrees. The raw soymilk is boiled in an open way for 1 minute to obtain cooked soymilk, and then immediately add water to cool down. Cool down to 65°C within 10 seconds to obtain a slurry;

[0037] (4) coagulant is added in the slurry that step (3) obtains,...

Embodiment 3

[0041] Follow the steps below to make porous tofu:

[0042] (1) Wash and drain the fresh soybeans. The soybeans are composed of Anhui soybeans and Northeast soybeans with a weight ratio of 1:1.2. Add 6 times the weight of distilled water, transfer to a microwave oven for 3 minutes at 200W power, and take out After being cooled to room temperature, pretreated soybean beans are obtained;

[0043] (2) Soak the pretreated soybeans obtained in step (1) in water until flat pits appear in the middle of the watercress of the pretreated soybeans, and obtain soaked soybeans after taking them out;

[0044] (3) add water to the soaked soybeans obtained in step (2) and grind to obtain raw soymilk, the Baume degree of the raw soymilk is 10.5 degrees, the raw soymilk is boiled for 2 minutes under slight pressure to obtain cooked soymilk, and then immediately add water to cool down, Cool down to 66°C within 14 seconds to obtain a slurry;

[0045] (4) coagulant is added in the slurry that st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Baume degrees | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com