A kind of permeable non-slip floor tile and its manufacturing method

A manufacturing method and technology for floor tiles, which are applied in building structures, floors, layered products, etc., can solve the problems of easy dirt absorption, single surface color, no technical research reports, etc., and achieve good water permeability, improved decorative effect, Good anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

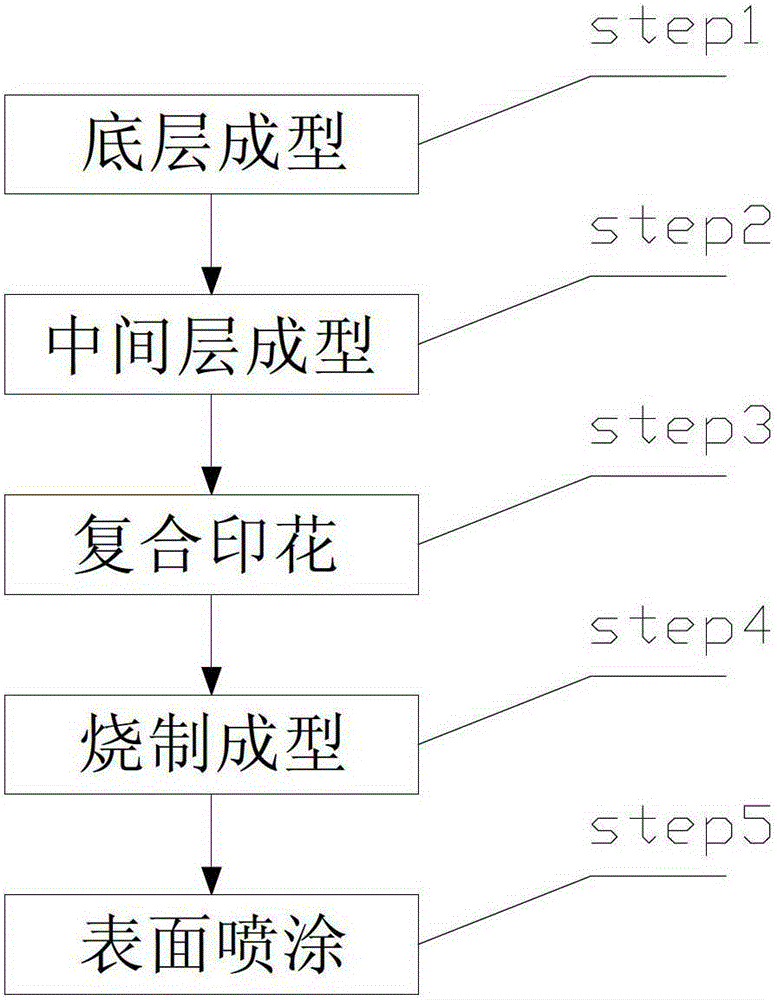

[0044] In order to further illustrate the essence of the present invention, the specific embodiments of the present invention are described as follows in conjunction with the accompanying drawings.

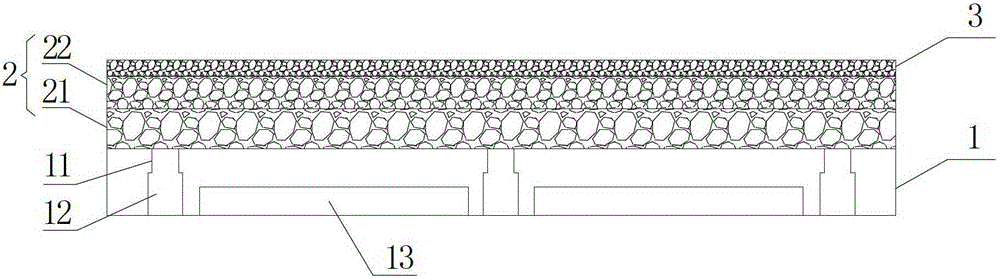

[0045] Example of permeable non-slip floor tiles

[0046] like figure 1 As shown, a permeable non-slip floor tile includes: a bottom layer 1, an intermediate layer 2 and a surface layer 3 that are combined together. Wherein, the bottom layer 1 is a dense ceramic layer, and the bottom layer 1 is provided with water removal holes 11 passing through its upper and lower surfaces; the middle layer 2 is a porous ceramic layer, and the porous ceramic layer 2 is provided with a plurality of equivalent apertures. A through hole not larger than the drain hole 11; the surface layer 3 is a decorative glaze layer, and the decorative glaze layer 3 is provided with a plurality of micropores whose equivalent diameter is not larger than the through hole.

[0047]Compared with the problem that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com