C/Z-type integrated cold roll forming machine

A cold roll forming machine and integrated technology, applied in the field of C/Z type integrated cold roll forming machine, can solve the problems of occupancy, low production efficiency, low transmission and control efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

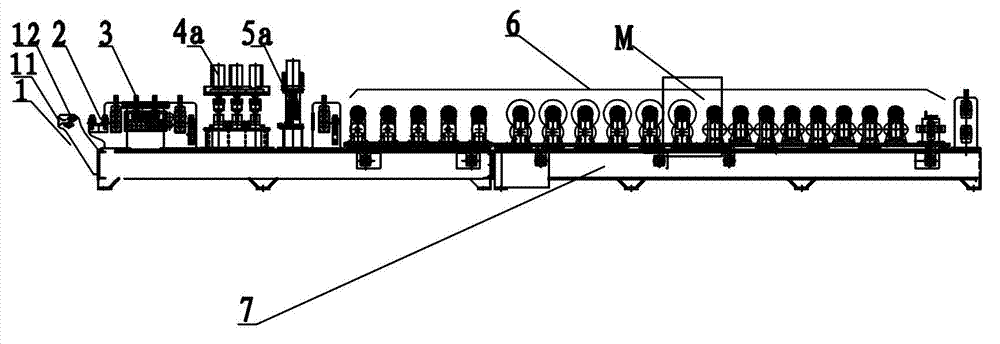

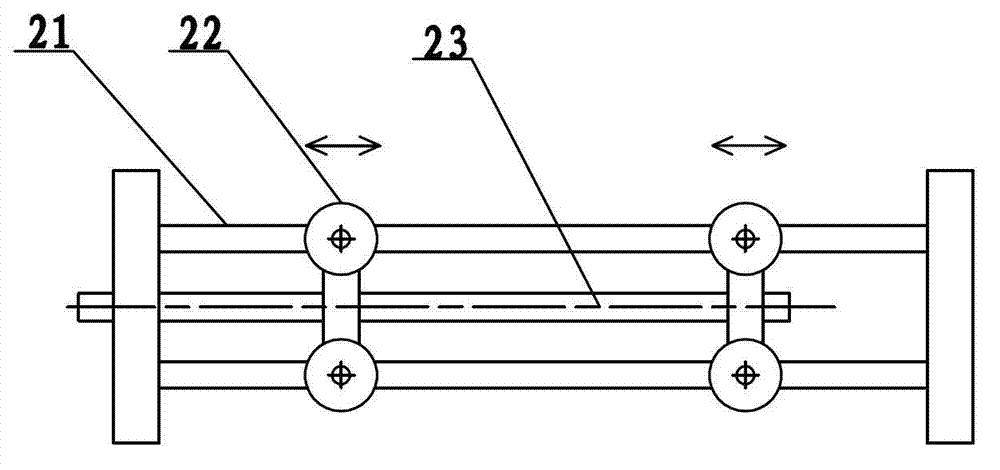

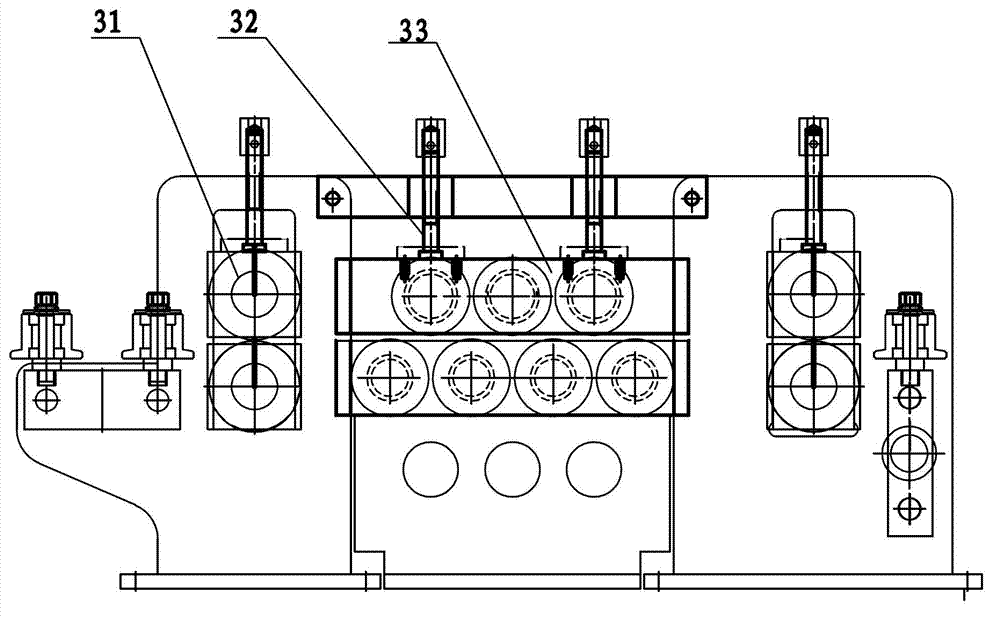

[0031] The C / Z type integrated cold bending forming machine of the present invention, combined with figure 1 , including a feeding table 1, a guiding device 2, a leveling device 3, a punching device 4, a shearing device 5 and a forming device 6 installed and connected in sequence, and the feeding table 1 mainly includes a feeding port 11 and a nip roller 12; combined figure 2 , the guide device 2 mainly includes a guide rod 21, a guide wheel 22 and a guide screw 23; image 3 , the leveling device 3 mainly includes a feeding shaft 31, a lifting screw 32 and a leveling shaft 33; Figure 6 , the forming device 6 can be automatically converted in C / Z type, including a symmetrical front forming roll 6a and a rear forming roll 6b, the front forming roll 6a and the rear forming roll 6b can move relative or opposite at the same time, the front forming roll Part 6a and rear forming roller part 6b all comprise frame 7, upper transmission shaft 62, lower transmission shaft 64 and upper...

Embodiment 2

[0035] The structure and setting of this embodiment are the same as that of Embodiment 1, the difference is that in combination Figure 7 , the feeding table, guiding device, leveling device, forming device, punching device and shearing device are connected in sequence, combined Figure 8 and Figure 9 , The punching device 4 adopts an independent connecting rod punching device 4b, and the shearing device adopts a stepless adjustable shearing device 5b. Wherein, the independent connecting rod punching device 4b includes an oil cylinder 47b, a push shaft 471b and a connecting rod 41b. The oil cylinder 47b drives the push shaft 471b to move up and down, and the connecting rod 41b is connected with the punch 42b. A guide device 46b is provided, and the push shaft 471b is connected with the connecting rod 41b through the guide device 46b. The guide device 46b includes a slider 462b and a guide rail 461b. The slider 462b is an inverted V shape, and the slider 462b is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com