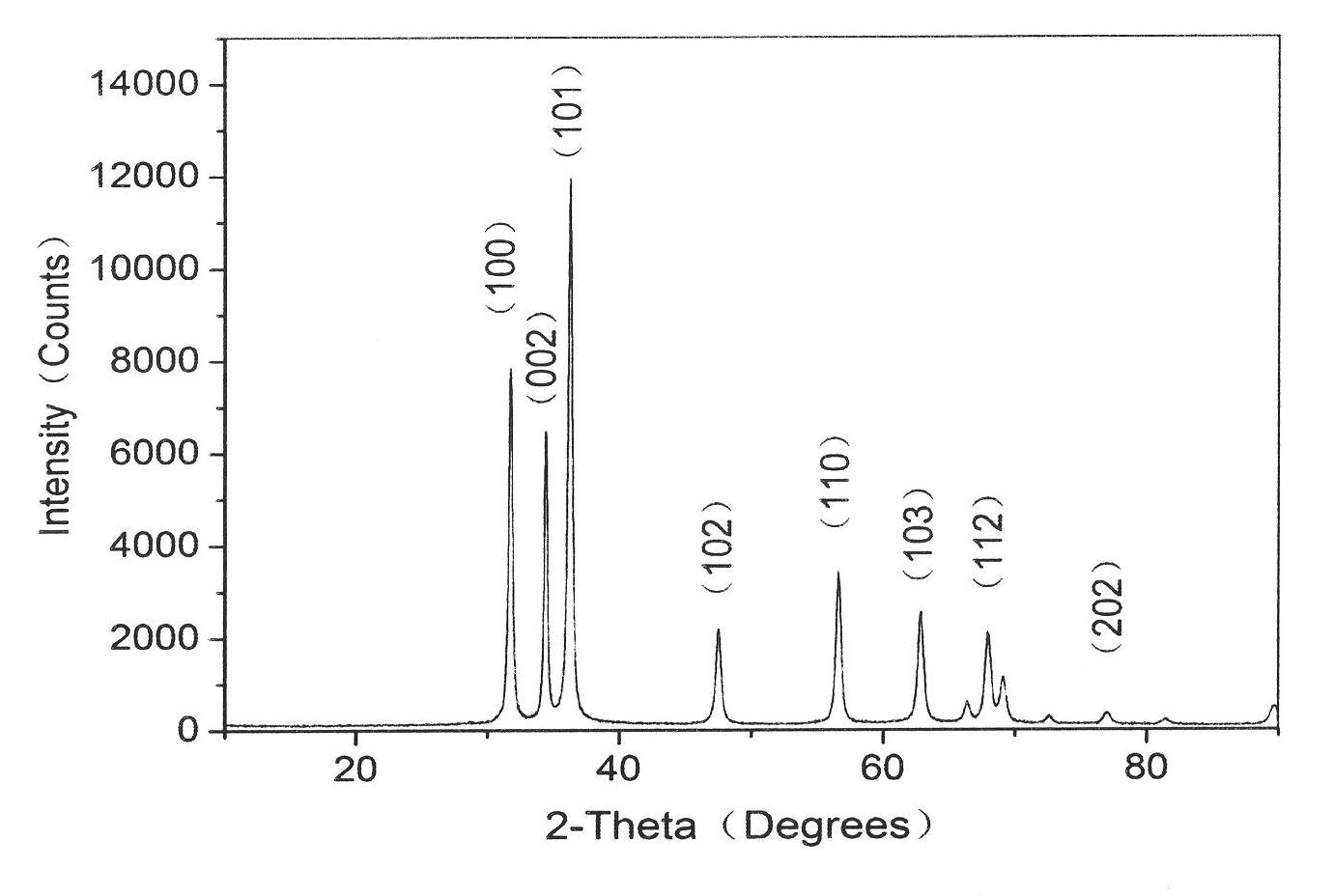

ZnO nano powder in sheet uniform porous structure as well as preparation method and applications thereof

A porous structure and nano-powder technology, which is applied in the direction of nanotechnology, structural parts, zinc oxide/zinc hydroxide, etc., can solve the problems that the equipment cannot achieve large-scale production, long production cycle, and promotion restrictions, and achieve low equipment requirements , Good product quality, uniform distribution of holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve the sodium carbonate raw material in water, prepare 0.2M sodium carbonate solution, put 25mL of the sodium carbonate solution in a flask, stir it magnetically under a constant temperature water bath condition of 90°C, and continuously apply a 50KV external electric field to the reaction vessel at the same time, Add 0.1M zinc nitrate hexahydrate solution dropwise to the reaction vessel, and after 2 hours of reaction, a milky white suspension is obtained;

[0032] (2) the milky white suspension obtained in step (1) is washed 5 times with deionized water, centrifuged, and dried to obtain the basic zinc carbonate precursor;

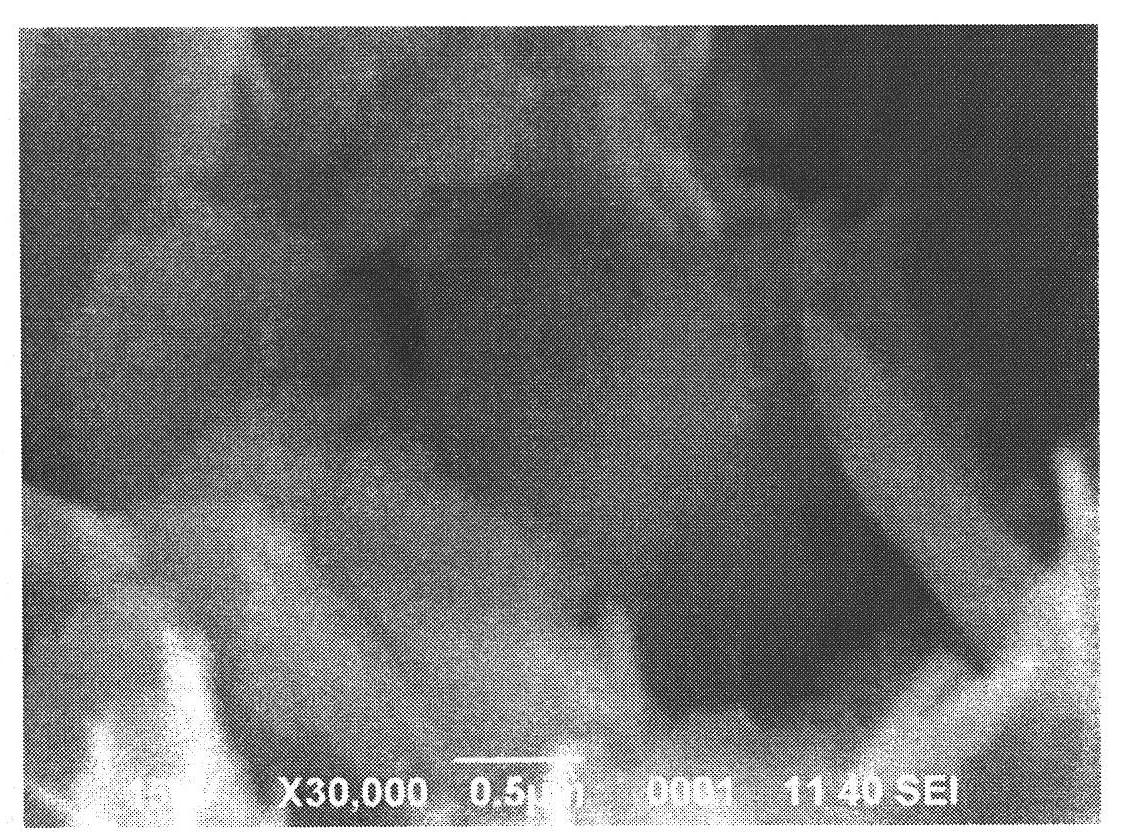

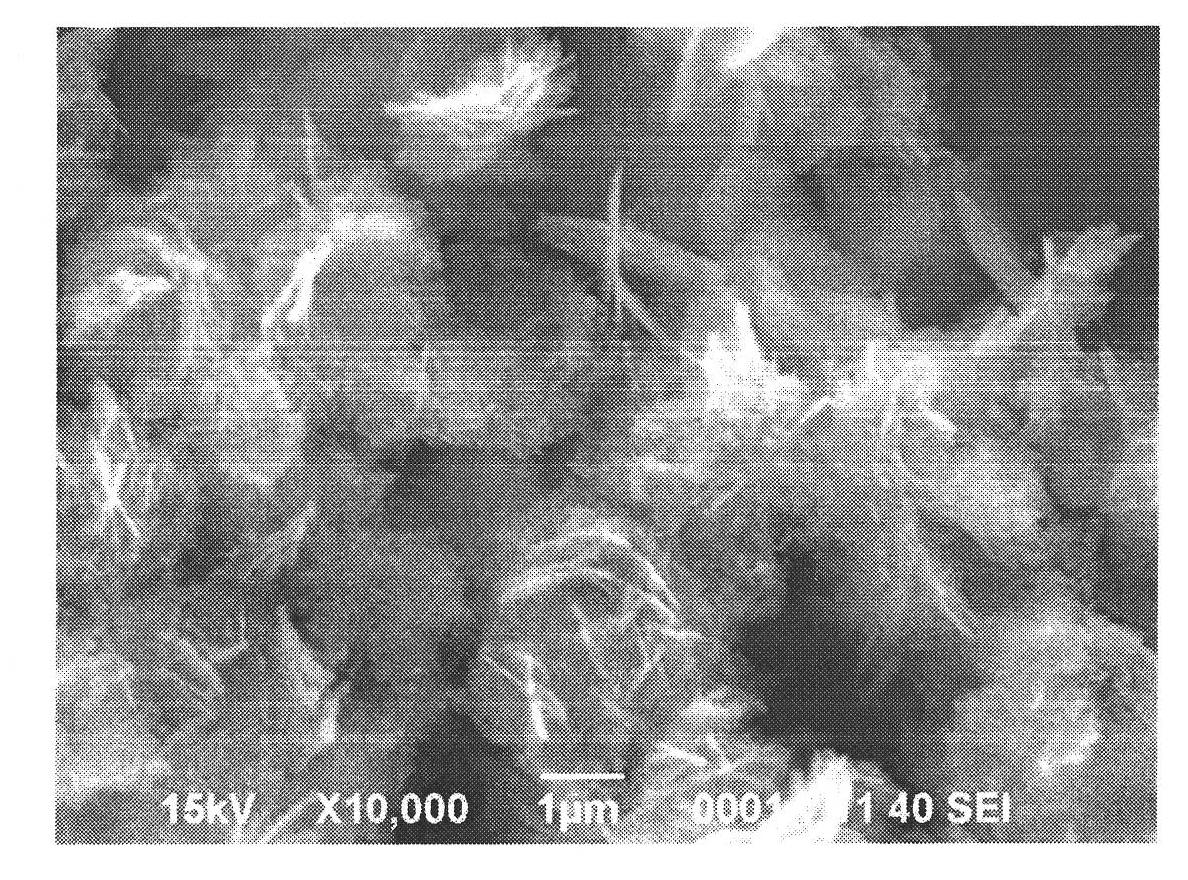

[0033] (3) Calcining the basic zinc carbonate precursor obtained in step (2) at 400° C. for 3 h to obtain ZnO nano-powder with sheet-like uniform porous structure.

Embodiment 2

[0035] (1) Sodium carbonate raw material is dissolved in water, the sodium carbonate solution of preparation 0.4M, get this sodium carbonate solution 25mL in the flask, under the constant temperature water-bath condition of 90 ℃, magnetic force stirs, and continuously applies 10KV external electric field to reaction container simultaneously, Add 0.3M zinc nitrate hexahydrate solution dropwise to the reaction vessel, and after 2 hours of reaction, a milky white suspension is obtained;

[0036] (2) the milky white suspension obtained in step (1) is washed 5 times with ethanol, centrifuged, and dried to obtain the basic zinc carbonate precursor;

[0037] (3) Calcining the basic zinc carbonate precursor obtained in step (2) at 350° C. for 3 hours to obtain ZnO nanopowder with sheet-like uniform porous structure.

Embodiment 3

[0039] (1) Sodium carbonate raw material is dissolved in water, the sodium carbonate solution of preparation 0.6M, get this sodium carbonate solution 25mL in the flask, under the constant temperature water-bath condition of 80 ℃, magnetic force stirs, and continuously applies 50KV external electric field to reaction container simultaneously, Add 0.5M zinc nitrate hexahydrate solution dropwise to the reaction vessel, and after reacting for 2 hours, a milky white suspension is obtained;

[0040] (2) the milky white suspension obtained in step (1) is washed 5 times with deionized water and ethanol, centrifuged, and dried to obtain the basic zinc carbonate precursor;

[0041] (3) Calcining the basic zinc carbonate precursor obtained in the step (2) at 300° C. for 3 hours to obtain ZnO nano powders with sheet-like uniform porous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com