Foam-like magnetic chitosan adsorbent and preparation method thereof

A chitosan and foam-like technology, which is applied in the field of foam-like magnetic chitosan adsorbent and its preparation, can solve the problems of adsorbent adsorption performance influence, uneven distribution of pores, complicated preparation method, etc., and achieve pore size and distribution The effect of uniformity, uniform hole size, and uniform hole distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

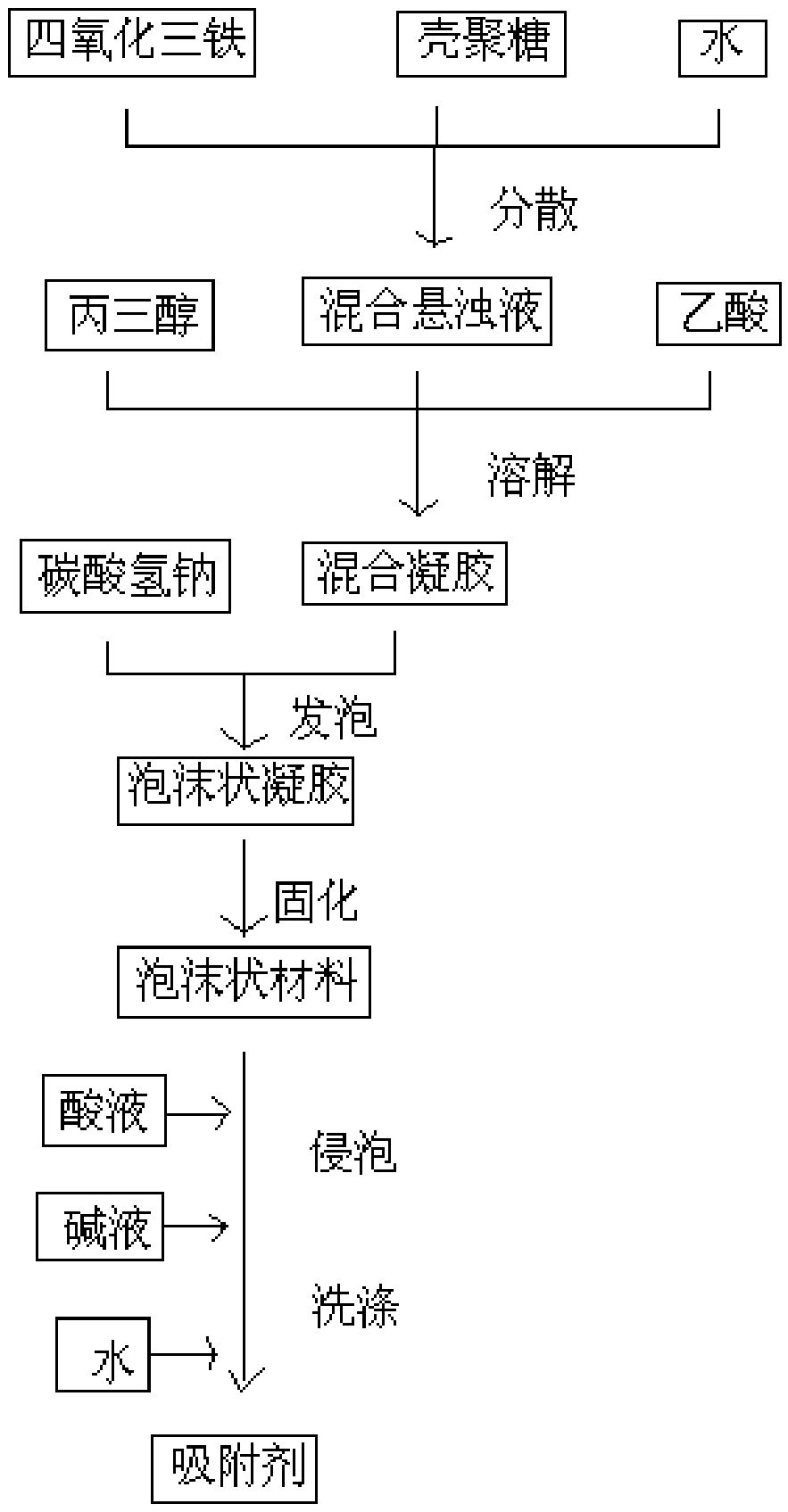

[0030] 1. Put 1.25g of ferric oxide and 1.8g of chitosan powder in 50mL of deionized water, and disperse evenly to obtain a mixed suspension; add 1.5g of acetic acid and 25g of glycerol in turn to the mixed suspension , dissolved under mechanical stirring to obtain a mixed gel;

[0031] 2. Add 6g of sodium bicarbonate to the mixed suspension and stir. When the volume of the solution expands to 2-3 times, stop stirring to obtain a foamy gel;

[0032] 3. Let the foamy gel stand at 25°C for 1.5 hours, and solidify to obtain a foam material;

[0033] 4. Soak the foam material in 0.1mol / L sulfuric acid solution to remove unreacted sodium bicarbonate until no foam is produced; then soak in 1.0mol / L sodium hydroxide solution for 40min; finally use deionization to repeatedly rinse the foam Square, until becoming neutral, obtains foamy magnetic chitosan adsorbent of the present invention.

Embodiment 2

[0035] 1. Place 0.25g of ferric oxide and 1g of chitosan powder in 50mL of deionized water, and disperse evenly to obtain a mixed suspension; add 0.6g of acetic acid and 10g of glycerol in turn to the mixed suspension, Dissolved under mechanical stirring to obtain a mixed gel;

[0036] 2. Add 2g of sodium bicarbonate to the mixed suspension and stir. When the volume of the solution expands to 2-3 times, stop stirring to obtain a foamy gel;

[0037]3. Let the foamy gel stand at 30°C for 0.5 hours, and solidify to obtain a foam material;

[0038] 4. Soak the foam material in 0.05mol / L sulfuric acid solution to remove unreacted sodium bicarbonate until no foam is generated; then soak in 1.5mol / L sodium hydroxide solution for 30min; finally use deionization to repeatedly rinse the foam Square, until becoming neutral, obtains foamy magnetic chitosan adsorbent of the present invention.

Embodiment 3

[0040] 1. Put 2.5g of ferric oxide and 2.5g of chitosan powder in 50mL of deionized water, and disperse evenly to obtain a mixed suspension; add 2.25g of acetic acid and 37.5g of glycerol to the mixed suspension in turn Alcohol, dissolved under mechanical stirring to obtain a mixed gel;

[0041] 2. Add 10g of sodium bicarbonate to the mixed suspension and stir. When the volume of the solution expands to 2-3 times, stop stirring to obtain a foamy gel;

[0042] 3. Let the foamy gel stand at 25°C for 2 hours, and solidify to obtain a foam material;

[0043] 4. Soak the foam material in 0.2mol / L sulfuric acid solution to remove unreacted sodium bicarbonate until no foam is produced; then soak in 0.5mol / L sodium hydroxide solution for 50min; finally use deionization to repeatedly rinse the foam Square, until becoming neutral, obtains foamy magnetic chitosan adsorbent of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com