Self-adhesive aluminium plastic compound water-proof anti-corrosion coiled material

An aluminum-plastic composite and anti-corrosion coil technology, which is applied in the direction of roofing, roofing, and infrastructure engineering using flexible materials, can solve the problems of low adhesion fastness between aluminum foil and rubber composite layer, complicated construction, and pollution. The effect of facilitating instrument leak detection and preventing hidden dangers of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

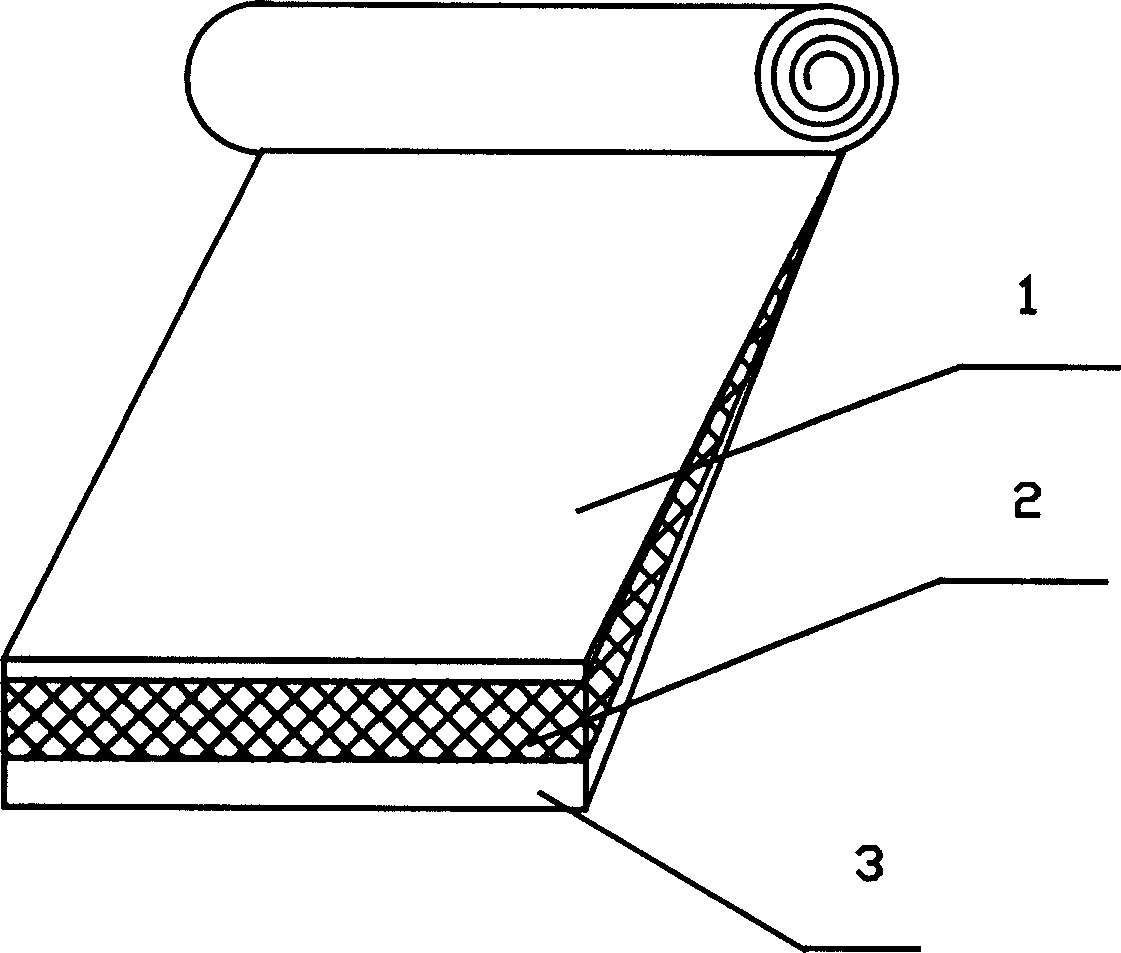

[0018] Reference attached figure 1 , The self-adhesive aluminum-plastic composite waterproof and anti-corrosion coil of the present invention is a multi-layer composite structure, which is a surface layer 1, an intermediate layer 2 and an isolation layer 3 from top to bottom.

[0019] The surface layer 1 is an AL-HDPE film. AL-HDPE film is produced by HDPE blown film process and HDPE film vacuum sputtering aluminum process. Due to the aluminum foil layer, the instrument can be used for pinhole voltage leakage test during construction and application, which can effectively prevent hidden dangers in construction quality.

[0020] The middle layer 2 is a self-adhesive non-woven fabric reinforced rubber asphalt layer. It adopts non-woven hot-dip glue technology and composite film technology, and can use SBS coil machine and asphalt felt machine....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com