Foamed ceramic insulation board and preparation method thereof

A technology of foamed ceramics and thermal insulation boards, which is applied in the direction of ceramic products, ceramic material production, clay products, etc., can solve the problems of endangering the safety of people's lives and property, unsatisfactory waterproof and fireproof performance, and poor thermal insulation effect. The process is non-toxic and harmless, the combination is dense, and the effect of low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

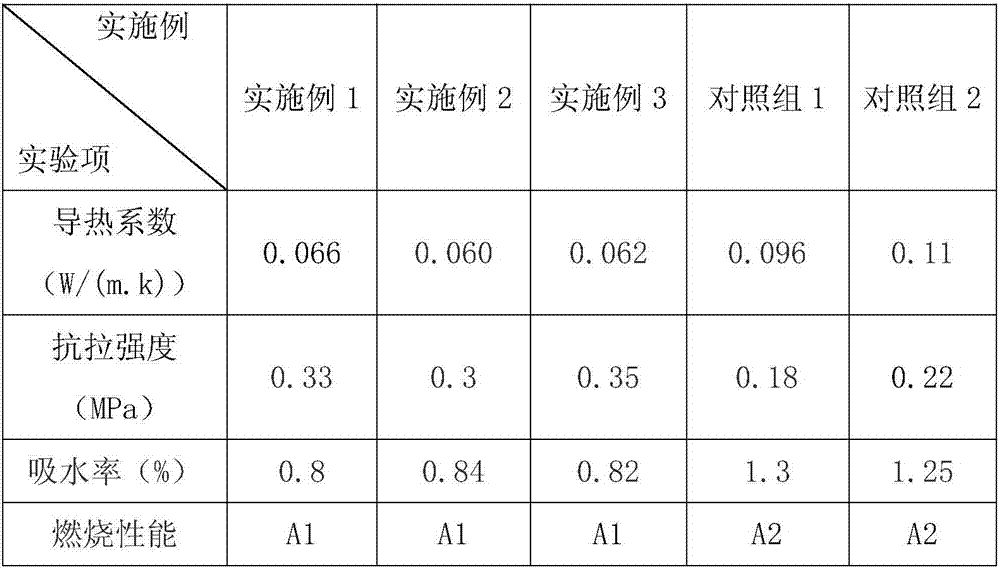

Examples

Embodiment 1

[0027] A foamed ceramic insulation board, prepared from the following raw materials in parts by weight: 45 parts of waste glass ceramic powder, 25 parts of phosphorus tailings, 25 parts of kaolin, 10 parts of potassium sodium feldspar, 12 parts of fly ash, calcined talc 7 parts, 6 parts of bentonite, 8 parts of silicon powder, 3 parts of talcum powder, 8 parts of calcium carbonate, 6 parts of magnesium carbonate, 10 parts of water glass, 3 parts of foaming agent, 0.5 parts of anionic surfactant and 1 part of dispersant.

[0028] Wherein, the particle size of the silicon powder is 400nm.

[0029] Wherein, the foaming agent is made of the following raw materials in parts by weight: 40 parts of silicon carbide, 15 parts of calcium carbonate and 30 parts of iron oxide.

[0030] Wherein, the anionic surfactant is a carboxylate anionic surfactant.

[0031] Wherein, the dispersant is one of sodium polyphosphate, sodium silicate and sodium carbonate.

[0032] A foamed ceramic insula...

Embodiment 2

[0041] A foamed ceramic insulation board, characterized in that it is made from the following raw materials in parts by weight: 35 parts of waste glass ceramic powder, 20 parts of phosphorus tailings, 15 parts of kaolin, 5 parts of potassium albite feldspar, and 8 parts of fly ash 4 parts of calcined talc, 2 parts of bentonite, 4 parts of silicon powder, 1 part of talc powder, 3 parts of calcium carbonate, 2 parts of magnesium carbonate, 5 parts of water glass, 1 part of foaming agent, 0.3 parts of anionic surfactant and dispersing 0.5 parts of the agent.

[0042] Wherein, the particle size of the silicon powder is 300nm.

[0043] Wherein, the foaming agent is made of the following raw materials in parts by weight: 30 parts of silicon carbide, 10 parts of calcium carbonate and 20 parts of iron oxide.

[0044] Wherein, the anionic surfactant is a carboxylate anionic surfactant.

[0045] Wherein, the dispersant is one of sodium polyphosphate, sodium silicate and sodium carbona...

Embodiment 3

[0055] A foamed ceramic insulation board, characterized in that it is made from the following raw materials in parts by weight: 65 parts of waste glass ceramic powder, 30 parts of phosphorus tailings, 35 parts of kaolin, 15 parts of potassium albite feldspar, and 16 parts of fly ash 10 parts of calcined talc, 10 parts of bentonite, 12 parts of silicon powder, 6 parts of talc powder, 12 parts of calcium carbonate, 10 parts of magnesium carbonate, 15 parts of water glass, 5 parts of foaming agent, 0.8 parts of anionic surfactant and dispersing 1.5 parts.

[0056] Wherein, the particle size of the silicon powder is 500nm.

[0057] Wherein, the foaming agent is made of the following raw materials in parts by weight: 50 parts of silicon carbide, 20 parts of calcium carbonate and 40 parts of iron oxide.

[0058] Wherein, the anionic surfactant is a carboxylate anionic surfactant.

[0059] Wherein, the dispersant is one of sodium polyphosphate, sodium silicate and sodium carbonate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com