Ceramic electric heating carrier and preparing method thereof

A carrier and electric heating technology, applied to clay products, other household appliances, heating element materials, etc., can solve the problems of low control temperature, inability to make an independent heater, unfavorable continuous heating, etc., achieve uniform spacing and reduce mold making The effect of plant investment and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

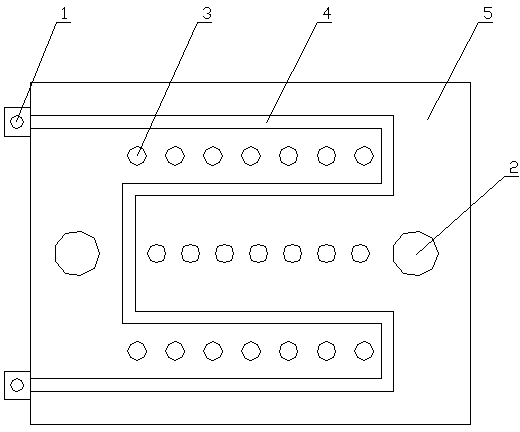

[0043] A ceramic electric heating carrier, including a heating carrier 5, a heating wire 4 is arranged inside the heating carrier 5, and a heating wire connector 1 is installed at both ends of the heating wire 4, such as figure 1 , 2 As shown, the heating carrier 5 is a high-temperature ceramic material, and the heating carrier 5 is provided with an installation hole 2 and a heat dissipation hole 3 .

[0044] The heating carrier 5 is rectangular, circular, polygonal or irregular.

[0045] The heating wire 4 is a high temperature heating wire.

[0046] The preparation method of a ceramic electric heating carrier includes raw material preparation and gel injection molding process, and the raw material preparation includes

[0047] 1) Raw material preparation weight ratio: kaolin 35-40%, spodumene 20-25%, aluminum titanate 2-5%, quartz 16-20%, alumina 6-8%, talc 4-7%, silicon carbide 10-15%;

[0048] 2) Synthesis of raw materials;

[0049] 3) Ball milling, mixing and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com