Modified rubber concrete

A technology of rubber concrete modification, which is applied in the field of building materials, can solve the problems of large dispersion of test data, lack of compactness of concrete bond, and decline of mechanical properties of rubber concrete, so as to achieve density increase, avoid water repellency and clumping phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

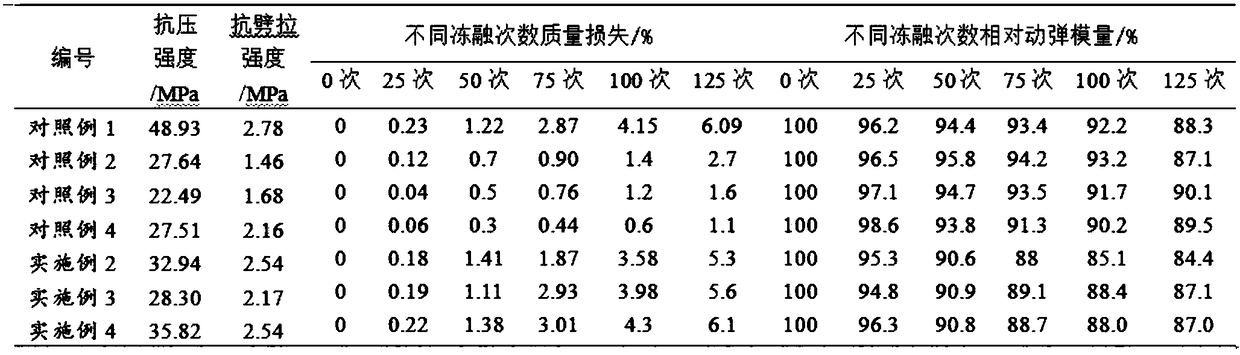

Examples

Embodiment 1

[0032] A method for modifying rubber particles, comprising the steps of:

[0033] 1) In parts by weight, take 7 parts of rubber granules and soak them in tap water for 7-10 days, then take them out until the soaked rubber granules sink completely without air bubbles on the surface of the granules. odor;

[0034] 2) In parts by weight, take 1 part of quick-setting agent and 4 parts of cement and mix evenly;

[0035] 3) Mix the wet rubber particles in step 1) with the powder obtained in 2), stir for 3 minutes, then add an appropriate amount of water, and stir for another 5 minutes until the slump of the mixture is 6-10;

[0036] 4) Use a spatula to spread the mixture evenly on the clean cement floor so that the particles do not clump together. Each particle should be separated. After the particles are dry, sieve to remove excess impurities. After curing in water for 3 days, take them out when needed. Come out and dry until the surface of the particles is off-white. It can the...

Embodiment 2

[0040] Modified rubber concrete: replace part of the sand with rubber particles by 5% equal volume, and the weight ratio of each raw material is: cement: water: sand: gravel: rubber particles: water reducer = 430:151.7:593.75:1160:13.76:7.74 , and the rubber particles are modified according to the method of Example 1.

[0041] Mixing process:

[0042] 1) Take stones, cement, sand, rubber particles, water reducing agent and water according to the mixing ratio (wherein the quality of the rubber particles is the quality of the rubber particles before processing;

[0043] 2) Put the stones into the mixing pot first, then mix the rubber particles into the cement and add them into the mixing pot together, then add the water reducer and sand, start the mixing pot and stir for 10 seconds, and finally add water and mix for 2min30s.

Embodiment 3

[0045] Modified rubber concrete: rubber particles are replaced by 10% equal volume of sand, and the weight ratio of each raw material is cement: water: sand: gravel: rubber particles: water reducer = 430:151.7:562.5:1160:27.5:7.74, And the rubber particles are modified according to the method of Example 1. The mixing process is with reference to Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com