Construction method of protective walls of concrete antiskid piles

A construction method and anti-slide pile technology, applied in the field of concrete anti-slide pile retaining wall construction, can solve the problems of low work efficiency, long working process time, unfavorable formwork installation and removal, etc., and achieve the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

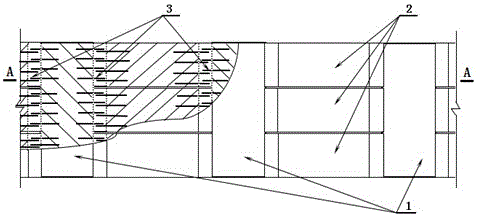

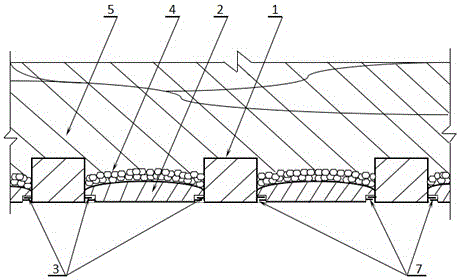

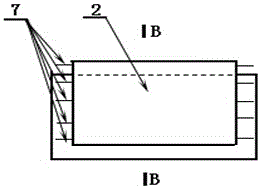

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. A construction method for a concrete anti-slide pile retaining wall, comprising the steps of:

[0023] (1) Excavate the rock and soil according to the process design requirements; after the rock and soil excavation is completed, set up concrete anti-slide pile grooves at intervals; excavate the rock and soil, adopt the conventional excavation construction method, and the construction volume required by the process is sufficient; the concrete is anti-sliding Pile grooves shall be dug and set according to the technical requirements, and the interval distance and quantity shall meet the requirements;

[0024] According to the requirements of process design, prefabricated concrete blocks; the distance between two adjacent concrete anti-slide pile grooves corresponds to the length of prefabricated concrete blocks, and the length of prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com