High temperature dust collector

A vacuum cleaner and high temperature technology, which is applied in the field of glass production equipment, can solve problems such as easy to cause dust, high flue temperature, and back-end equipment operation failure, and achieve the effect of ensuring non-stick and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

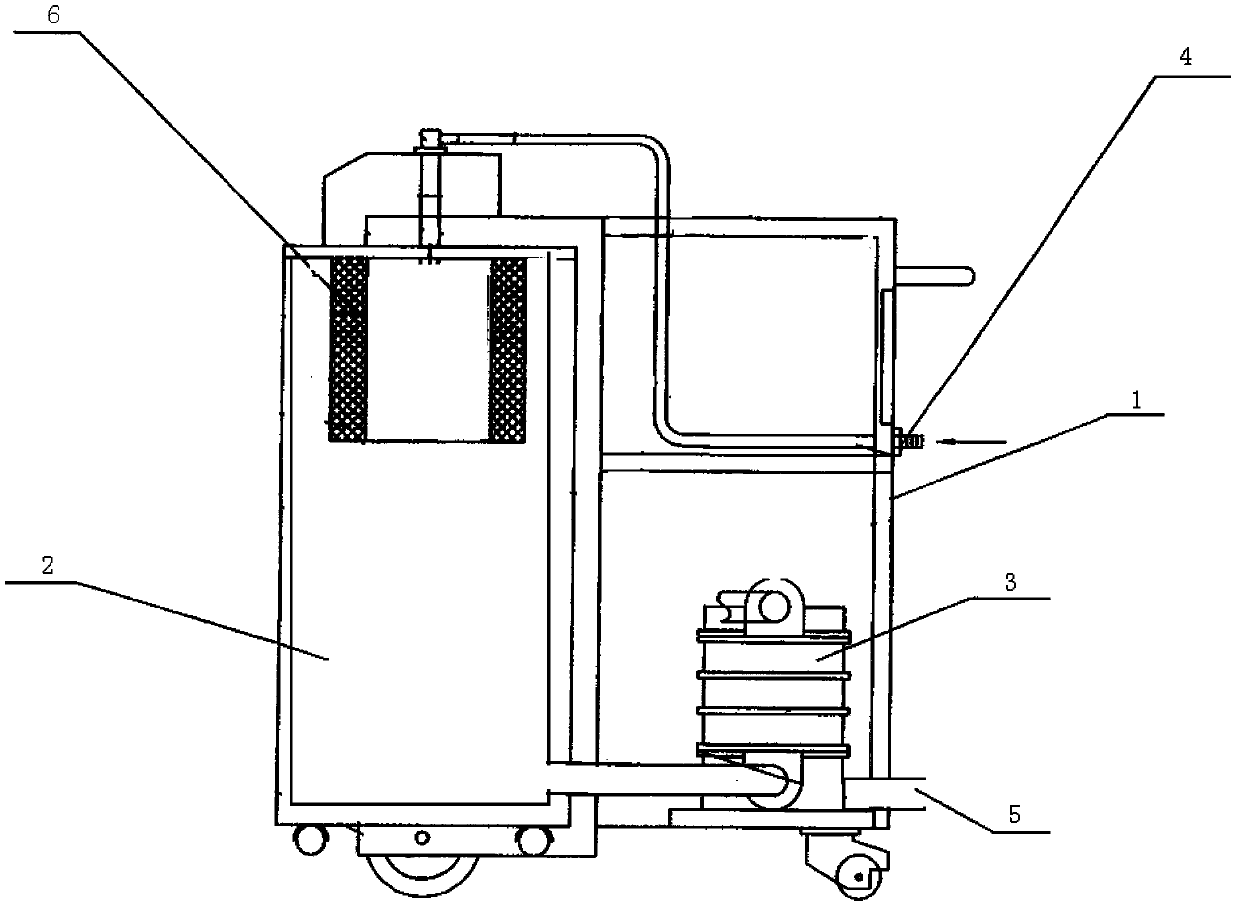

[0015] Hot vacuum cleaners, see figure 1 , including the body (1) and the air chamber (2), the fan (3), the air inlet pipe (4), the air outlet pipe (5), and the metal filter screen (6) arranged in the body (1), the air inlet pipe ( 4), the air chamber (2) is connected with the fan (3) and the air outlet pipe (5) in sequence, and the metal filter (6) is arranged between the air inlet pipe (4) and the air inlet of the air chamber (2).

[0016] The metal filter screen (6) is a 304 stainless steel metal filter screen with a gap of 400 meshes. It has been proved by long-term use that it can continuously withstand high temperatures of 800°C without deformation.

Embodiment 2

[0018] The high-temperature vacuum cleaner is basically the same as in Example 1, except that the metal filter (6) is a 316 stainless steel metal filter with a gap of 200 meshes. It has been proved by long-term use that it can continuously withstand high temperatures of 1000°C without out of shape.

Embodiment 3

[0020] The high-temperature vacuum cleaner is basically the same as that in Embodiment 1, except that the metal filter screen (6) is a high-temperature-resistant metal alloy filter screen with a gap of 200 meshes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com