Vacuum feed device

A feeding device and vacuum technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of filter blockage, reduction of filter area, and inability to use normally, so as to reduce labor and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

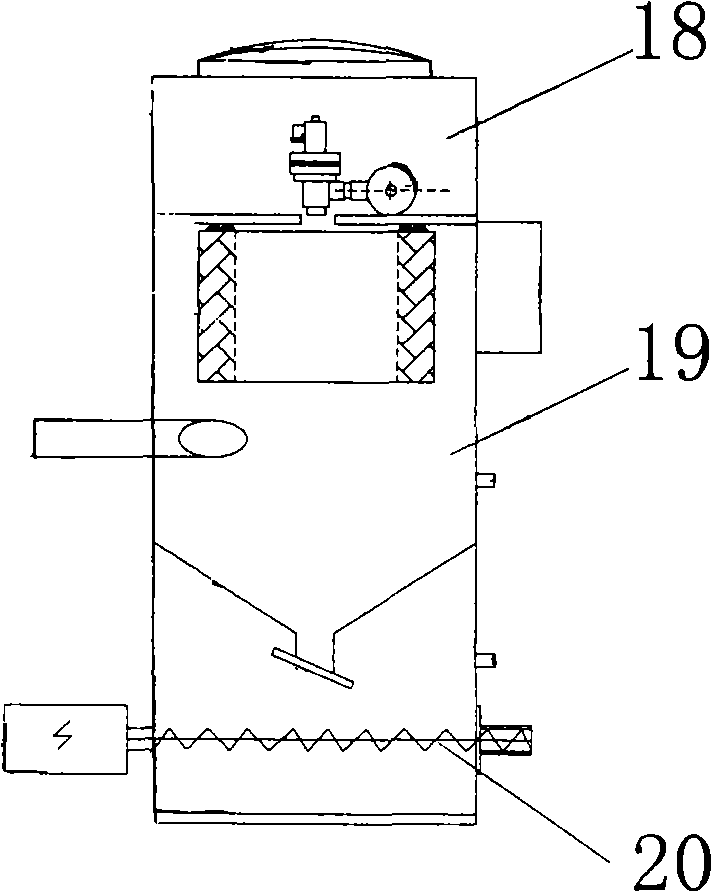

[0018] like figure 1 As shown, it is a schematic structural diagram of a vacuum feeding device, and the feeding device includes a vacuum separation device 18 , a silo storage device 19 and a material conveying device 20 connected in sequence.

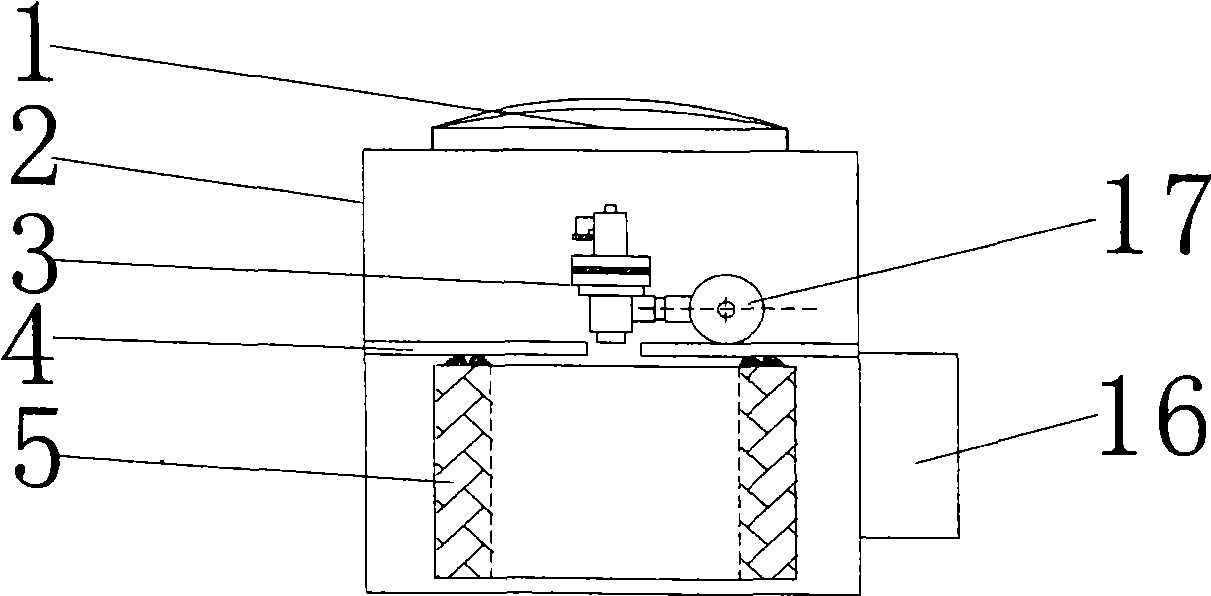

[0019] like figure 2 As shown, it is a schematic structural diagram of a vacuum separation device. The vacuum separation device 18 includes a housing 2, a vacuum generator 1 is provided on the top of the housing 2, a support 4 is provided in the middle of the inner side of the housing 2, and a blowback is provided on the support 4. The high-pressure gas storage cylinder 17, the blowback high-pressure gas storage cylinder 17 is connected to the pneumatic pulse valve 3, the filter 5 is provided at the lower part of the inner side of the casing 2, and the PLC control module 16 is arranged at the outer side of the casing 2;

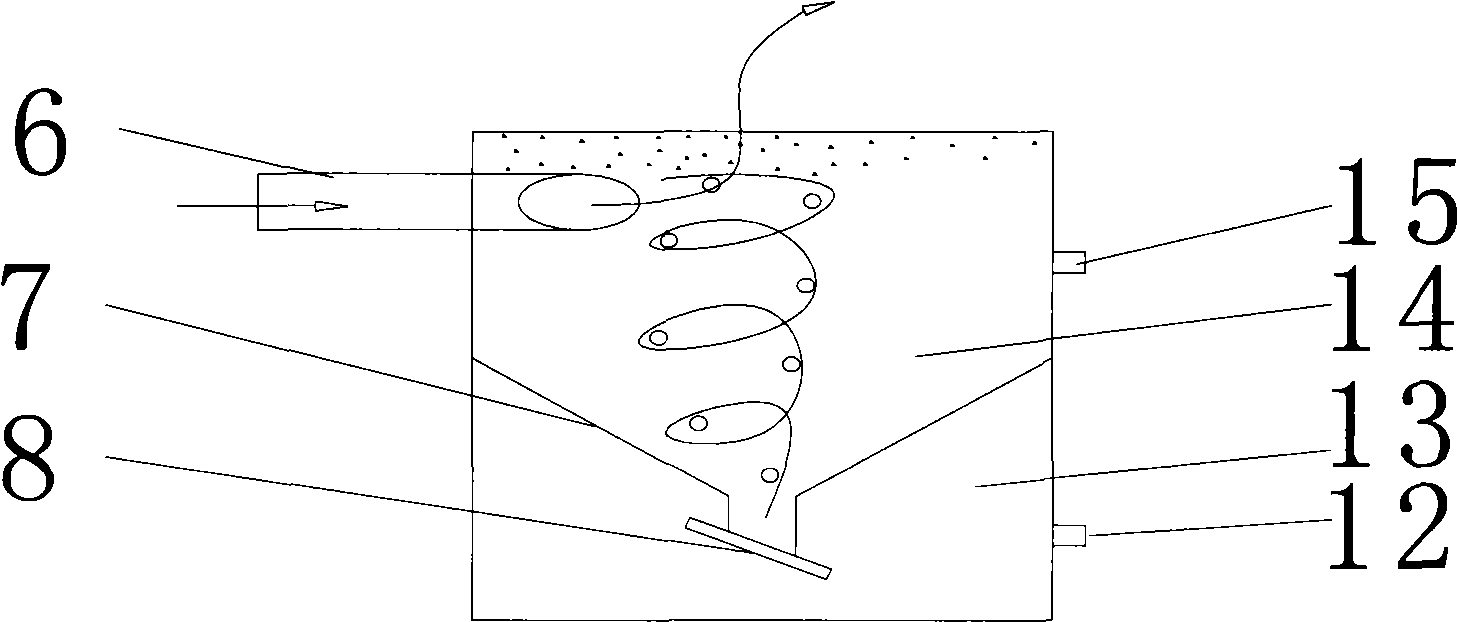

[0020] like image 3 As shown, it is a schematic diagram of the structure of the bin storage device. The bin stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com