Wafer processing equipment

A processing equipment and wafer technology, applied in stone processing equipment, sustainable manufacturing/processing, work accessories, etc., can solve problems affecting yield, wafer tearing, affecting processing efficiency, etc., to ensure cutting quality and guarantee Accuracy, the effect of ensuring completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

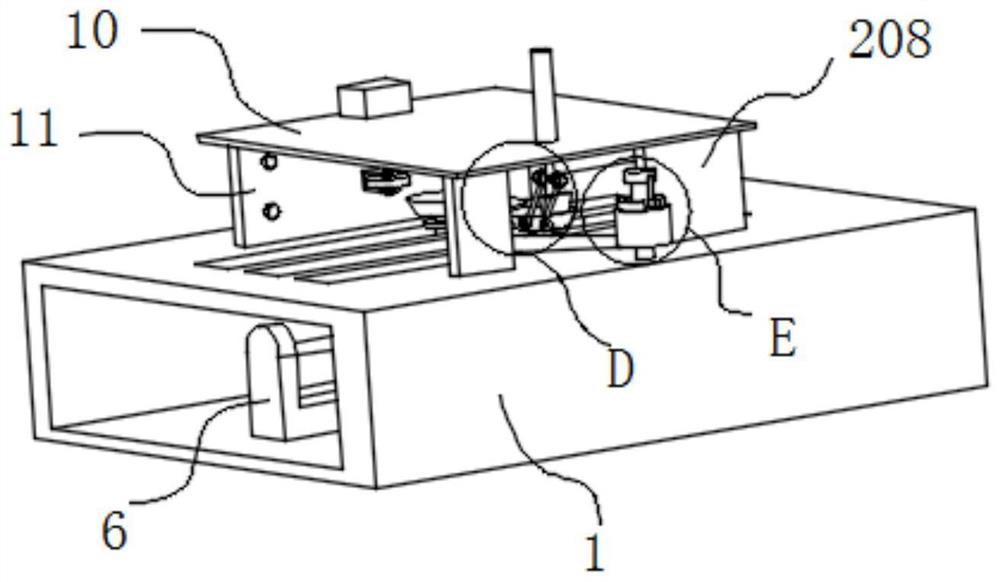

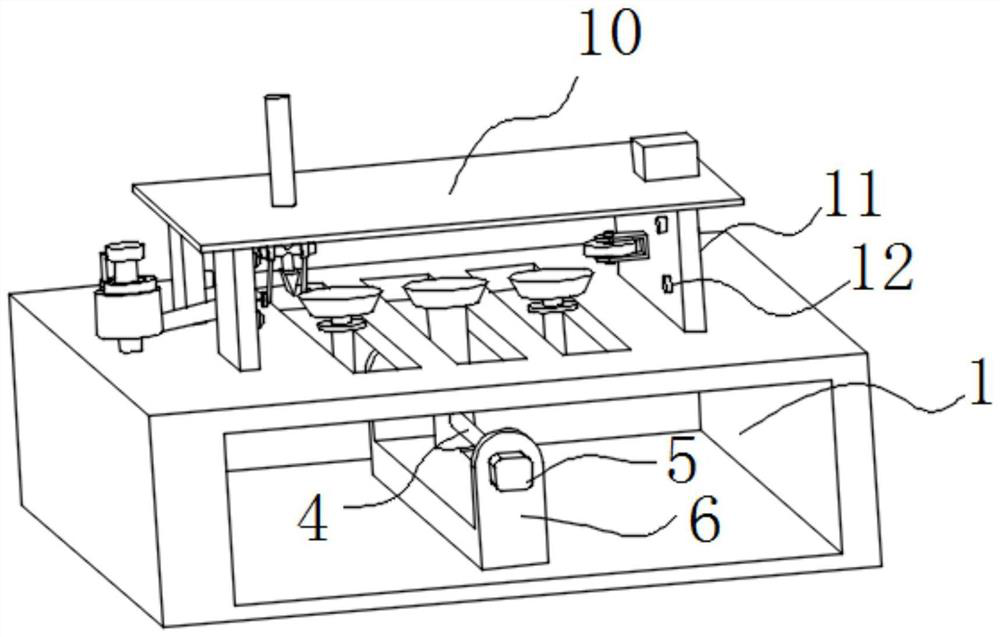

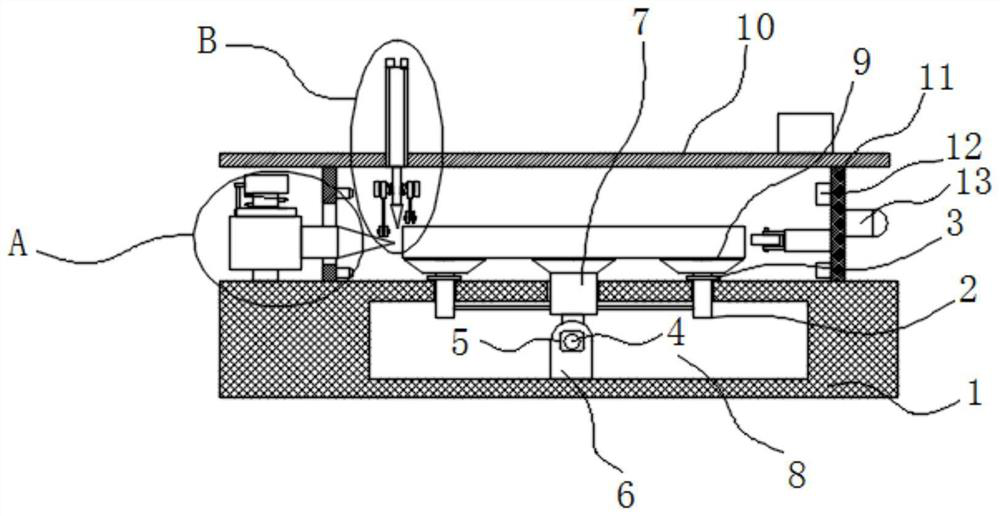

[0031] like Figure 1 to Figure 7As shown, a wafer processing equipment according to the present invention includes a movable frame 1, a driven rod 2, a limit plate 3, a screw rod 4, a motor 5, a mounting frame 6, an active rod 7, a sliding cavity 8, and a suction cup 9. Fixed frame 10, second baffle plate 11, light receiver 12, warning light 13, cutting cylinder 101, pneumatic rod 102, cutting knife 103, first reed 104, swing ring 105, swing lever 106, connecting rod 107 , roller 108, sleeve 201, limit rod 202, electrode ball 203, installation rod 204, limit cap 205, second reed 206, electrode ring 207, first baffle 208, needle 209 and toggle rod 210, The inside of movable frame 1 is provided with sliding cavity 8, and mounting frame 6 is fixed on the bottom side inner wall of sliding cavity 8, and motor 5 is installed on one side of mounting frame 6, and screw mandrel 4 is installed on the rotating shaft of motor 5, and sliding cavity 8 There are three sliding holes in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com