Fixtures for motor end shields

A technology for motor end caps and fixtures, which is applied to manufacturing tools, clamping, positioning devices, etc., can solve the problems of cumbersome operation, unstable quality, and low clamping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

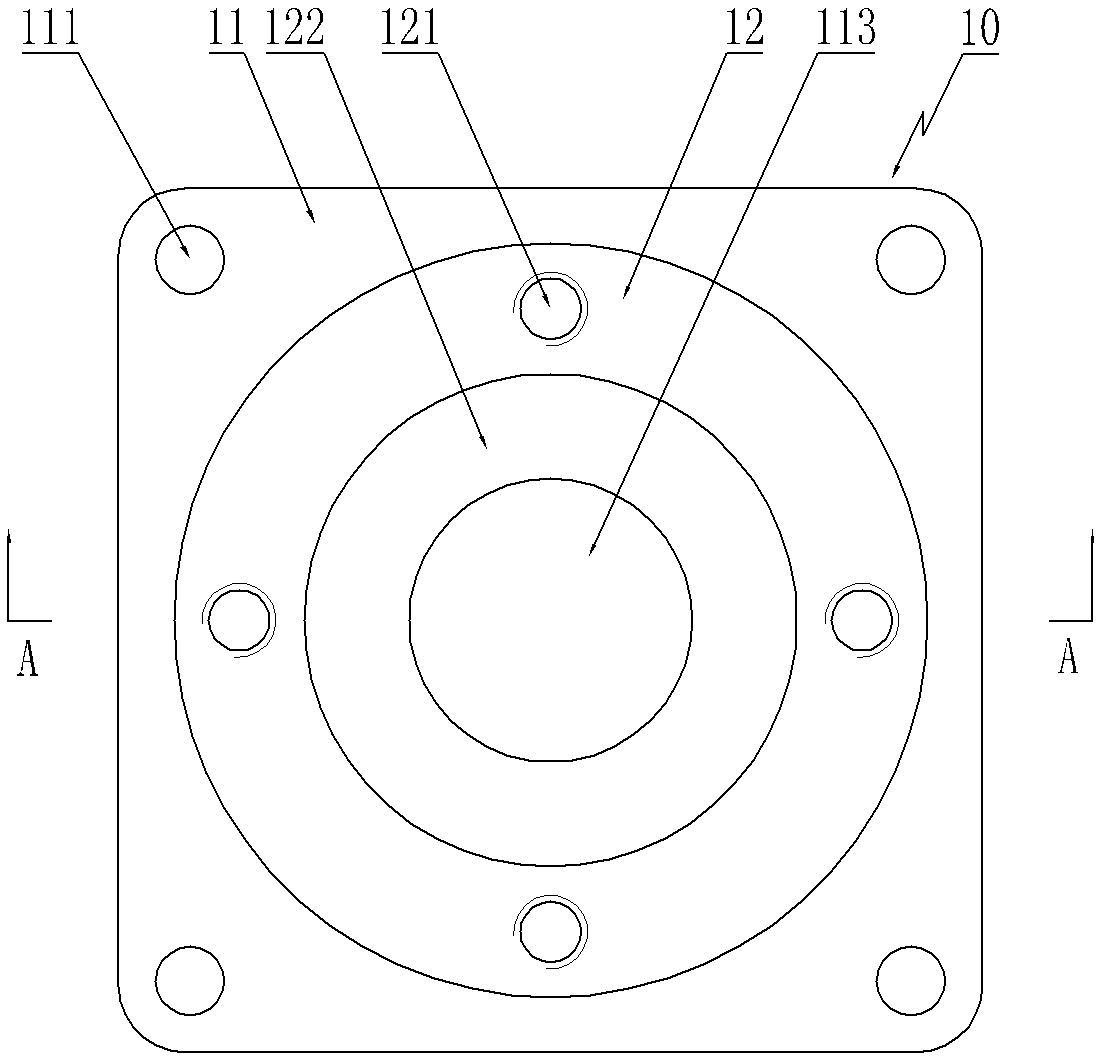

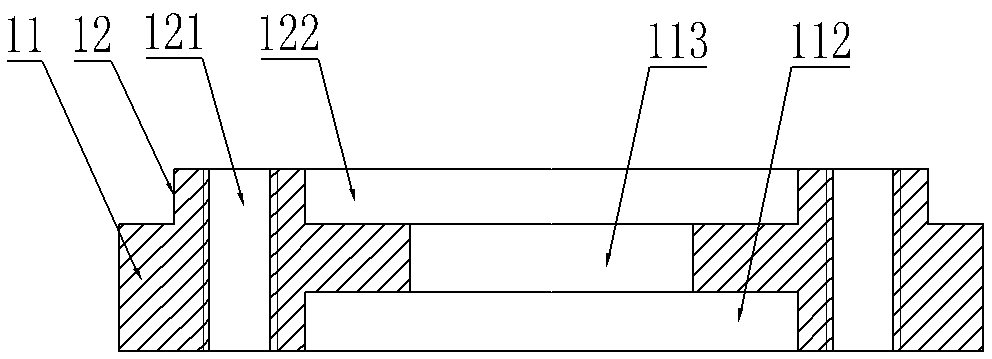

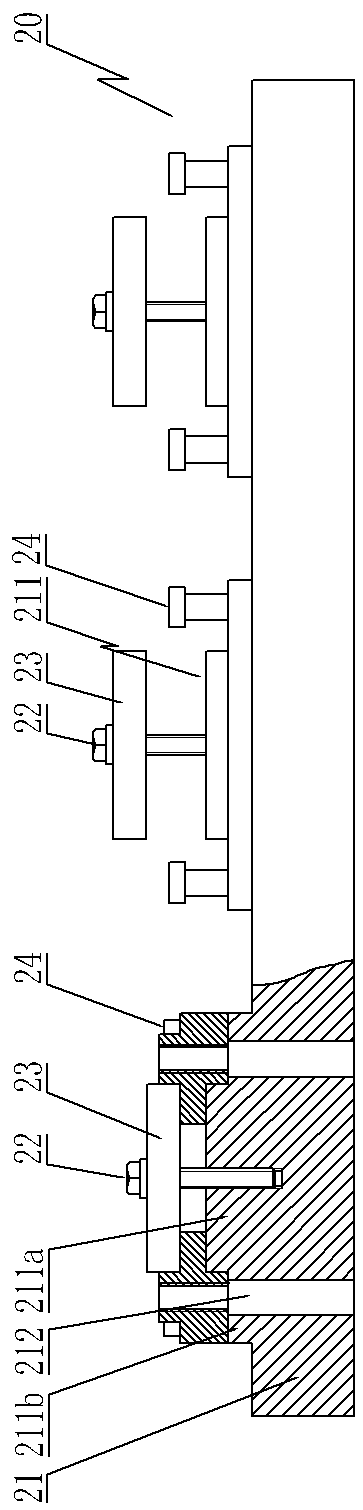

[0018] like Figure 1~Figure 4 As shown, the tooling fixture 20 of the motor end cover includes a bottom plate 21, a positioning mechanism and a press-fitting mechanism;

[0019] The positioning mechanism includes a step-shaped positioning column 211 and a positioning pin 24. Several stepped positioning columns 211 are arranged at intervals along the length direction of the base plate. Each step-shaped positioning column 211 is provided with a press-fitting mechanism. Shaped positioning post 211 includes an upper positioning part 211a and a lower supporting part 211b. The upper positioning part 211a cooperates with the bearing groove of the motor end cover. The threaded hole of the end cover, the blanking hole 212 matched with the light hole, the positioning hole, and the positioning pin 24 are inserted in the positioning hole;

[0020] The pressing mechanism includes bolts 22 and a pressing plate 23, the pressing plate 23 is connected to the stepped positioning column 211 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com