Peeling device for random number of cables

A cable and quantity technology, which is applied in the field of any number of cable peeling devices, can solve the problems of reducing recycling efficiency, increasing cost and operating procedures, and achieving the effect of shortening the spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

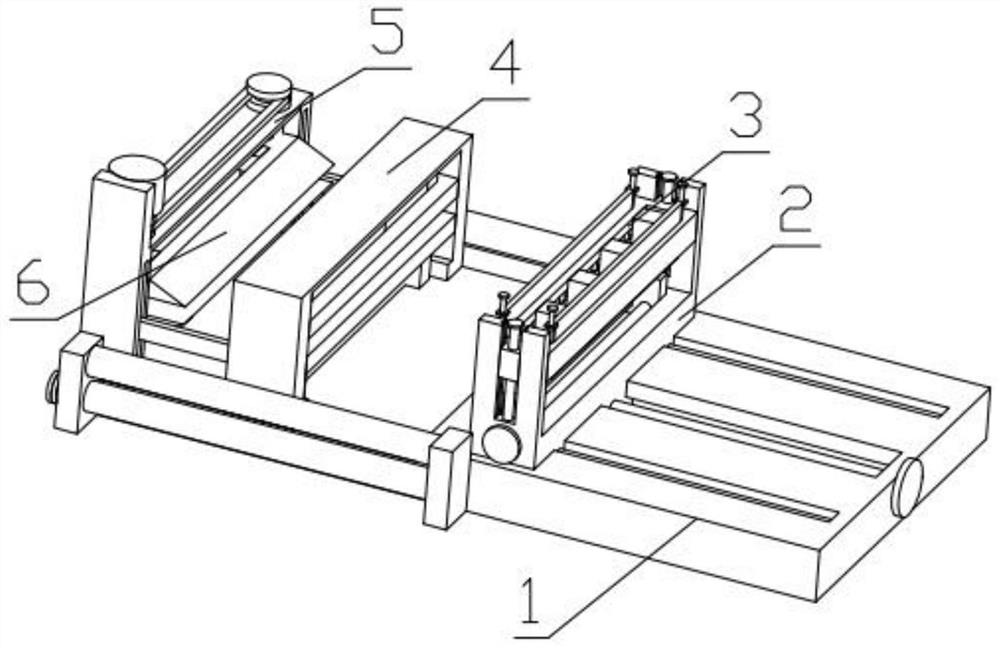

[0042] Combine below Figure 1-20 Describe this embodiment, a cable peeling device with any number, including a base 1, a cable positioning mechanism 2, a peeling mechanism 3, a core wire positioning mechanism 4, an adjustment mechanism 5 and a core wire peeling mechanism 6, the cable positioning The mechanism 2 is slidably installed in the groove provided on the base 1, the peeling mechanism 3 is fixedly installed on the cable positioning mechanism 2, the core wire positioning mechanism 4 is fixedly installed on the base 1, and the adjustment mechanism 5 is fixedly installed on the base 1. The wire peeling mechanism 6 is threadedly connected with the adjustment mechanism 5, and the core wire positioning mechanism 4 is fixedly connected with the core wire peeling mechanism 6.

specific Embodiment approach 2

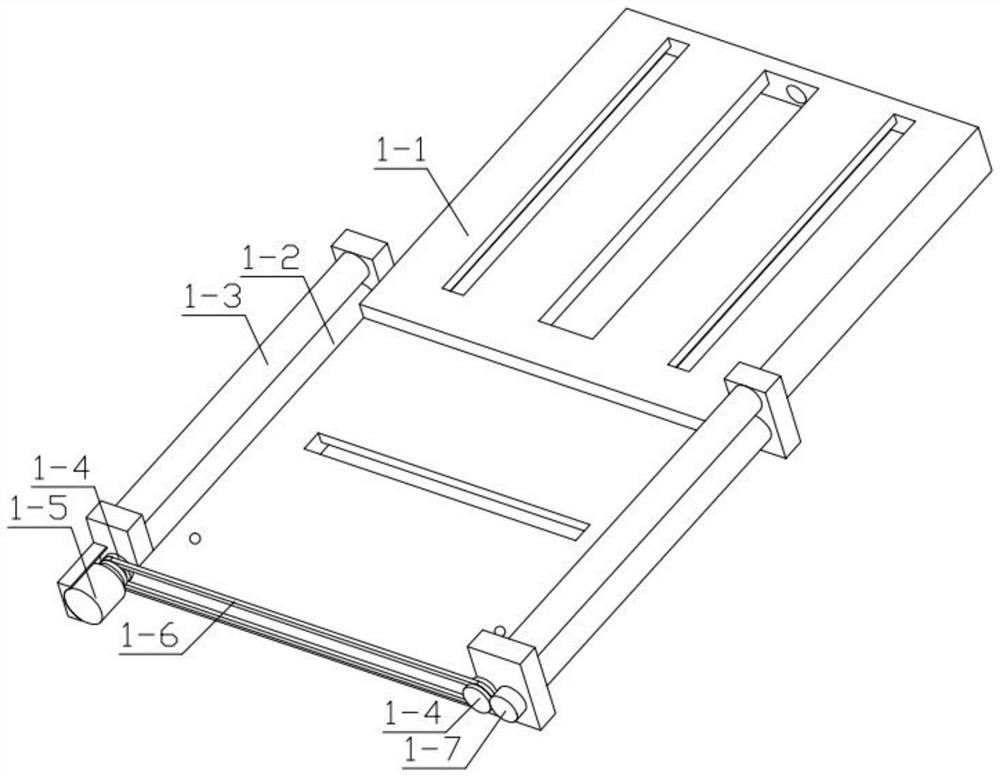

[0044] Combine below Figure 1-20 Describe this embodiment, this embodiment will further explain the first embodiment, the base 1 includes a base main body 1-1, a driving shaft 1-2, a driven shaft 1-3, a sprocket 1-4, and a driving motor 1 -5, chain 1-6, steering gear 1-7, the driven shaft 1-3 is installed in the groove provided on the base body 1-1 in rotation, and one end of the drive shaft 1-2 is installed in the base body 1-1 in rotation In the groove provided above, the other end of the drive shaft 1-2 passes through the base body 1-1 and is fixedly installed with a sprocket 1-4, and the other side of the sprocket 1-4 is fixedly installed on the drive motor 1-5. At the output end, the driving motor 1-5 is fixedly installed on the base body 1-1, the sprocket 1-4 is meshed with the chain 1-6, the steering gear 1-7 is meshed with the sprocket 1-4, and the steering gear 1-4 is meshed with the chain 1-6. 7 is fixedly installed on the drive shaft 1-2 on the other side.

specific Embodiment approach 3

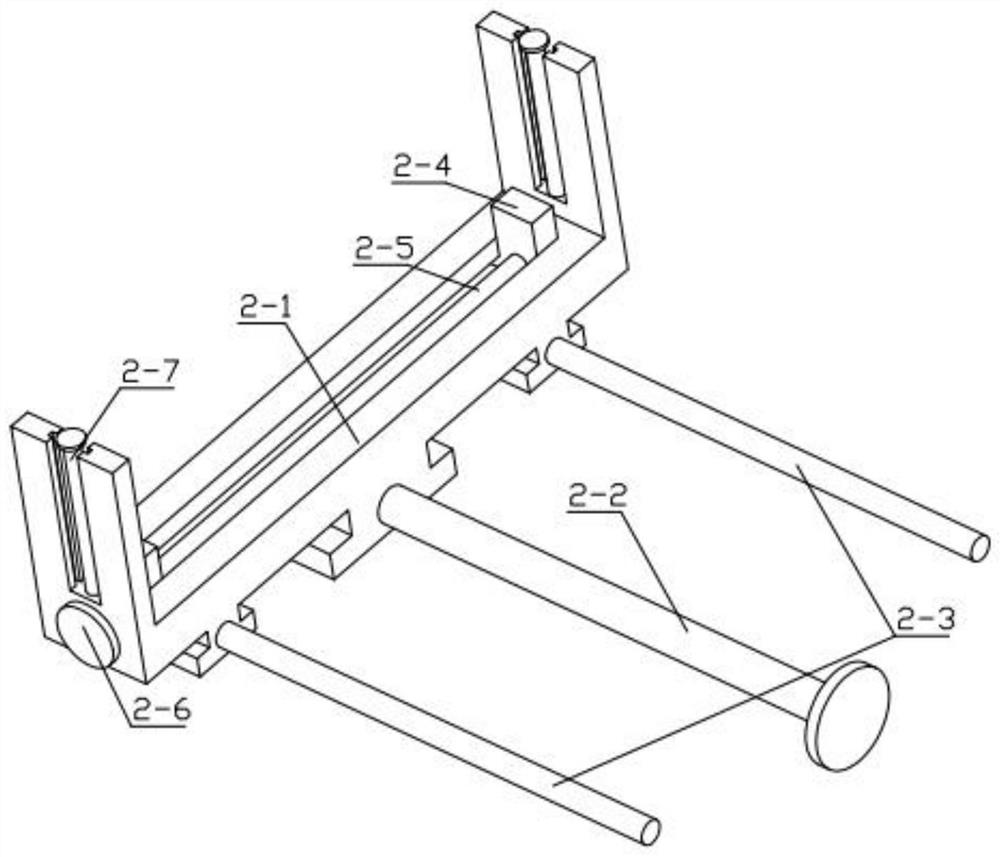

[0046] Combine below Figure 1-20 Describe this embodiment, this embodiment will further explain the second embodiment, the cable positioning mechanism 2 includes a U-shaped frame 2-1, a displacement threaded rod 2-2, a limit rod 2-3, an extrusion block 2- 4. Two-way threaded rod 2-5, rotating disk 2-6, vertical threaded rod 2-7, displacement threaded rod 2-2 is rotatably installed in the groove provided on the base body 1-1, and the limit rod 2-3 is fixed Installed on the base body 1-1, the displacement threaded rod 2-2 is threadedly connected with the U-shaped frame 2-1, and the U-shaped frame 2-1 is slidably installed in the groove provided on the base body 1-1, and the U-shaped frame 2 -1 is slidingly installed on the limit rod 2-3, and one end of the two-way threaded rod 2-5 is rotatably installed in the groove provided on the U-shaped frame 2-1, and the other end of the two-way threaded rod 2-5 passes through the U-shaped The frame 2-1 is fixedly installed with a rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com