Clamp of motor end cap

A technology of motor end cover and fixture, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., and can solve problems such as cumbersome operation, low clamping efficiency, and unstable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

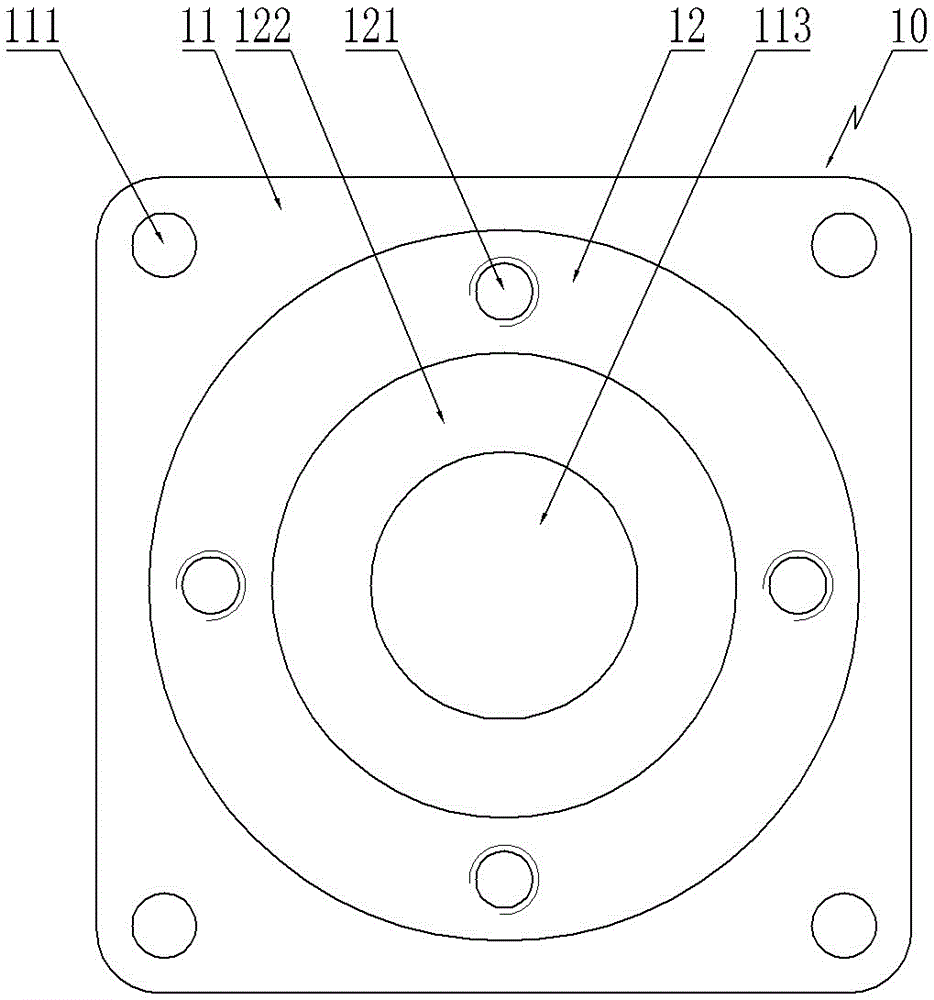

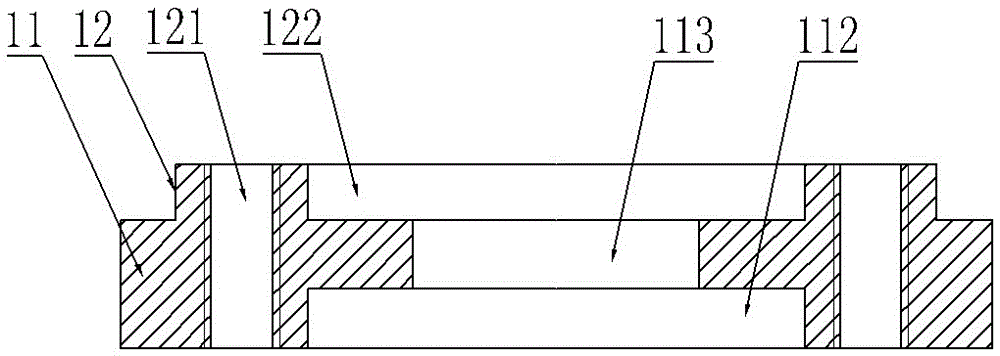

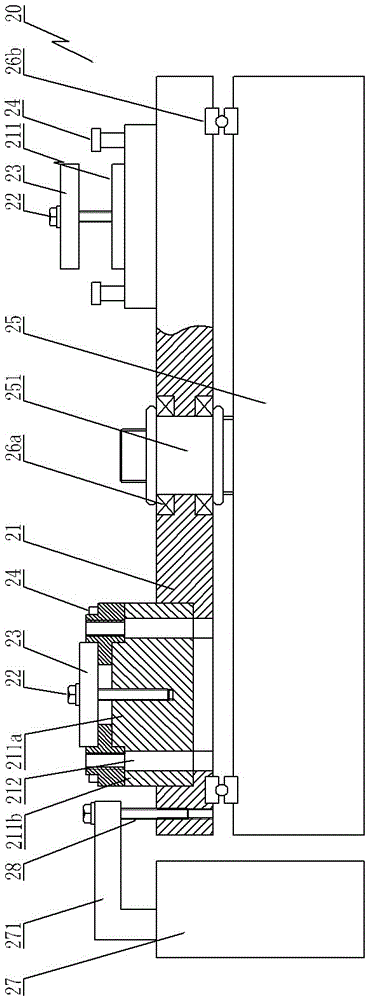

[0018] Such as Figure 1~Figure 3 As shown, the clamp 20 of the motor end cover includes a base plate 21, a turntable 25, a workpiece positioning mechanism, a workpiece pressing mechanism and a base plate positioning mechanism;

[0019] A rotating shaft 251 is fixed on the turntable 25, and the base plate is rotatably supported on the rotating shaft 251 through a roller bearing 26a. The upper end surface of the turntable and the lower end surface of the base plate are connected through a plane bearing 26b. Nuts are threaded at both ends of the rotating shaft axially, and the nuts are pressed into rollers. The inner ring of the sub-bearing;

[0020] The workpiece positioning mechanism includes a stepped positioning column 211 and a positioning pin 24,

[0021] A number of stepped positioning columns 211 are fixed on the base plate and distributed around the rotating shaft 251 in a circle. Each stepped positioning column 211 is embedded in the mounting hole of the base plate. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com