Enamel inner container for cooking utensil

A technology for cooking utensils and enamel, which is applied in the field of enamel inner tanks for cooking utensils, and can solve the problems of unsatisfactory solid food effects and poor non-stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

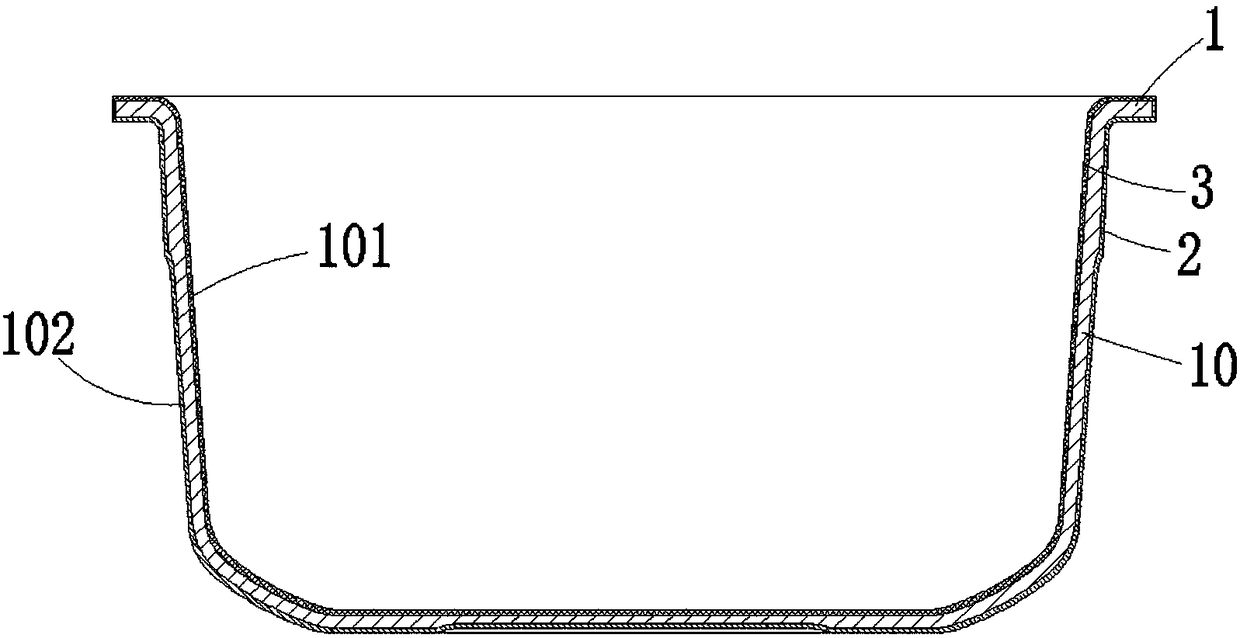

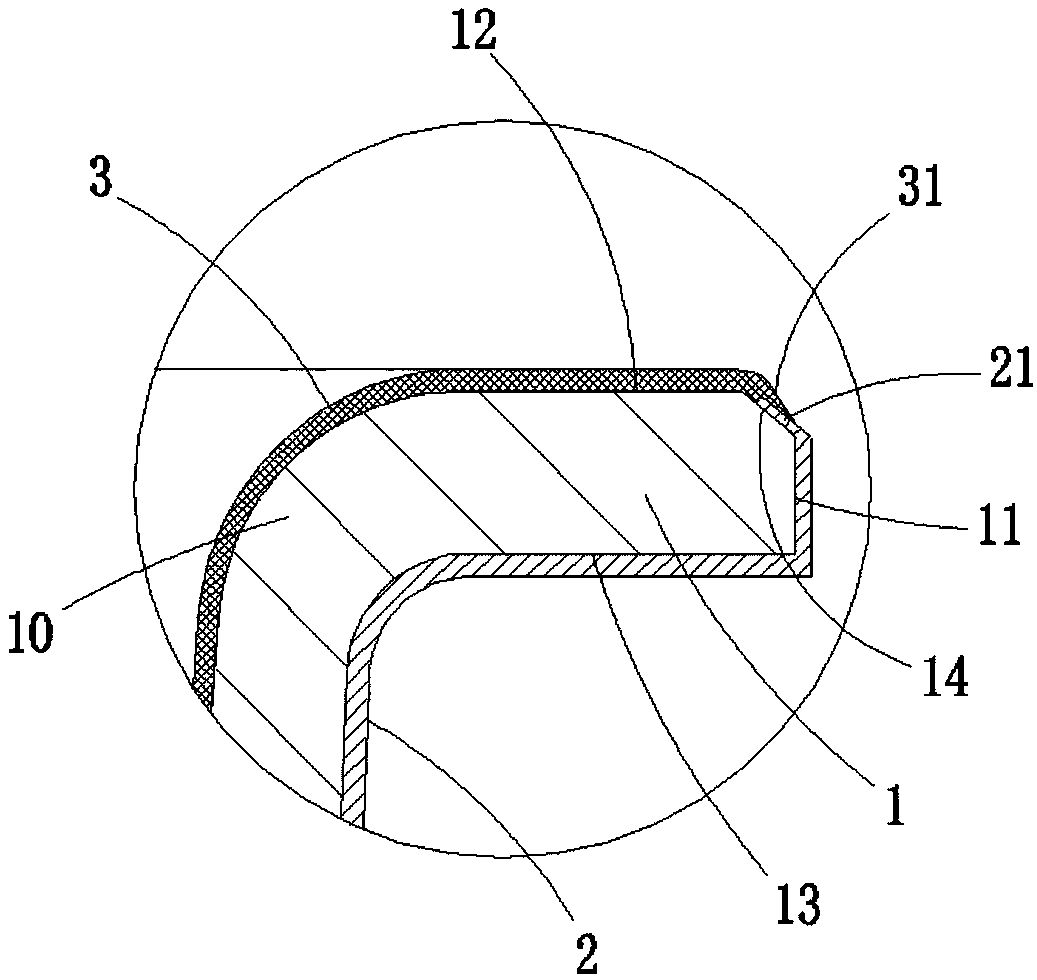

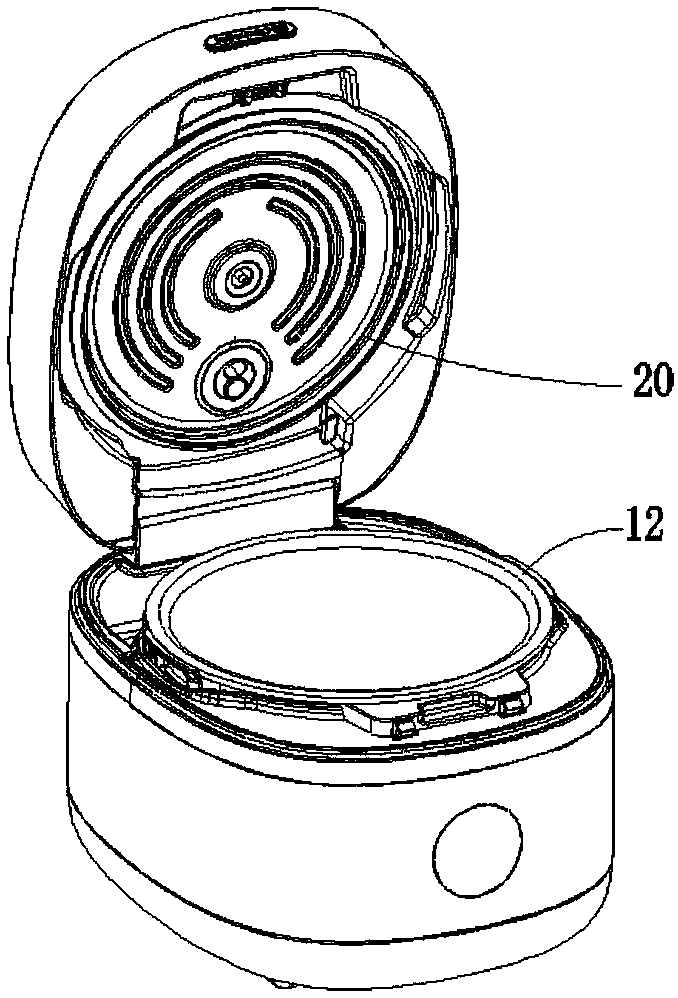

[0028] Please refer to Figure 1 to Figure 3 , which is a relevant illustration of Embodiment 1 of an enamel inner container for cooking utensils according to the present invention.

[0029] refer to figure 1 As shown, an enamel inner container for cooking utensils includes a cast iron container body 10, the outer surface of the cast iron container body 10 is sintered with an enamel glaze layer 2, and the inner surface of the cast iron container body 10 is sprayed with a non-stick coating 3, Wherein the material of the non-stick coating 3 is preferably Teflon. By spraying the non-stick coating 3 on the inner surface of the cast iron tank body 10, the non-stick property of the inner tank during cooking is ensured. The enamel layer 2 is sintered on the outer surface of the cast iron tank 10 to improve the corrosion resistance of the cast iron tank 10 and the appearance of the inner tank.

[0030] Refer again figure 2 As shown, the mouth of the cast iron tank 10 has a radially...

Embodiment 2

[0048] see Figure 4 , which is a diagram of Embodiment 2 of an enamel liner for cooking utensils according to the present invention. The difference from Embodiment 1 is that the positions where the enamel layer 2 is connected to the non-stick coating 3 are different, as follows.

[0049] The corner between the outer end surface 11 of the flange 1 and the bottom surface 13 of the flange 1 is a second corner 15 , and the position where the enamel layer 2 and the non-stick coating 3 are connected is located at the second corner 15 .

[0050] In this embodiment, because the position where the enamel layer 2 and the non-stick coating 3 are connected is located at the second corner 15, the connection between the enamel layer 2 and the non-stick coating 3 faces downward, so even if the cooking time leaks The gas will cause the condensed water to slip from the flange 1, and will not penetrate into the cast iron tank 10 from the joint, so as to obtain good corrosion resistance.

[0...

Embodiment 3

[0060] see Figure 5 , which is a diagram of Embodiment 3 of an enamel liner for cooking utensils according to the present invention. It differs from the above-mentioned embodiments in that an aluminum layer 4 is sprayed between the cast iron tank 10 and the non-stick coating 3 .

[0061] After spraying the aluminum layer 4, the bonding strength of the non-stick coating 3 is increased. In addition, the heat transfer performance of aluminum is better than that of iron, which can quickly transfer the heat of cast iron, thereby improving the heating efficiency.

[0062] Wherein, the thickness of the aluminum layer 4 is between 50-150 microns, preferably 75 microns, 100 microns and 125 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com