Patents

Literature

31results about How to "Appearance does not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

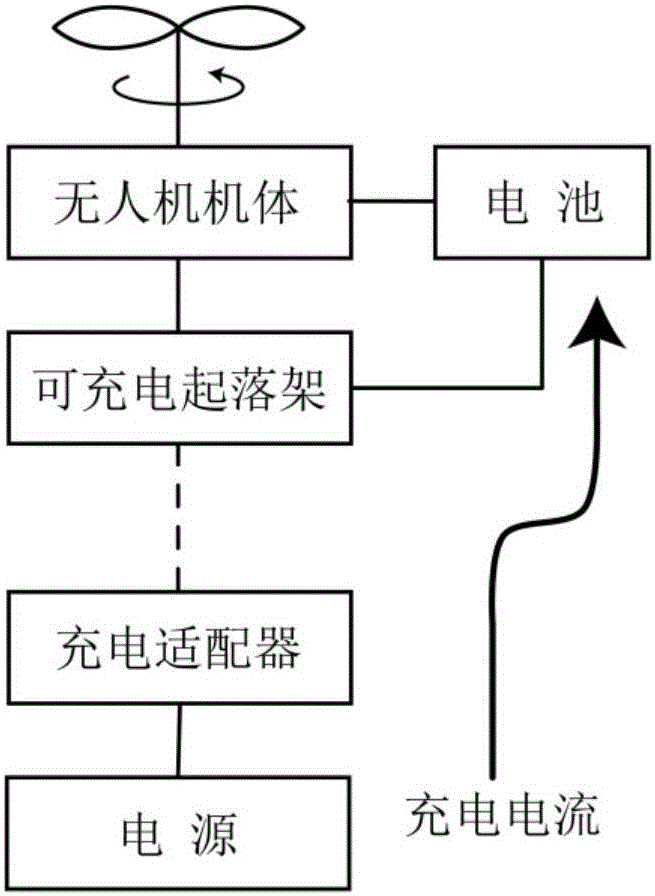

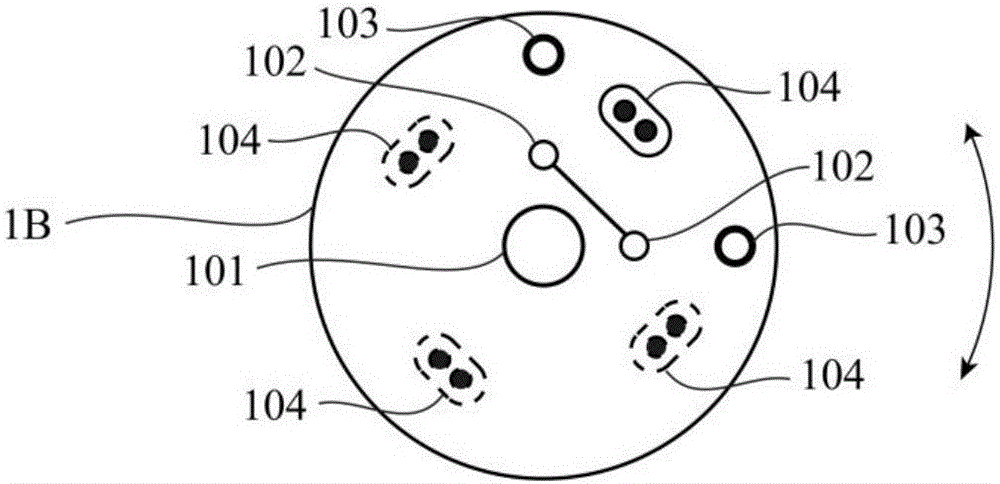

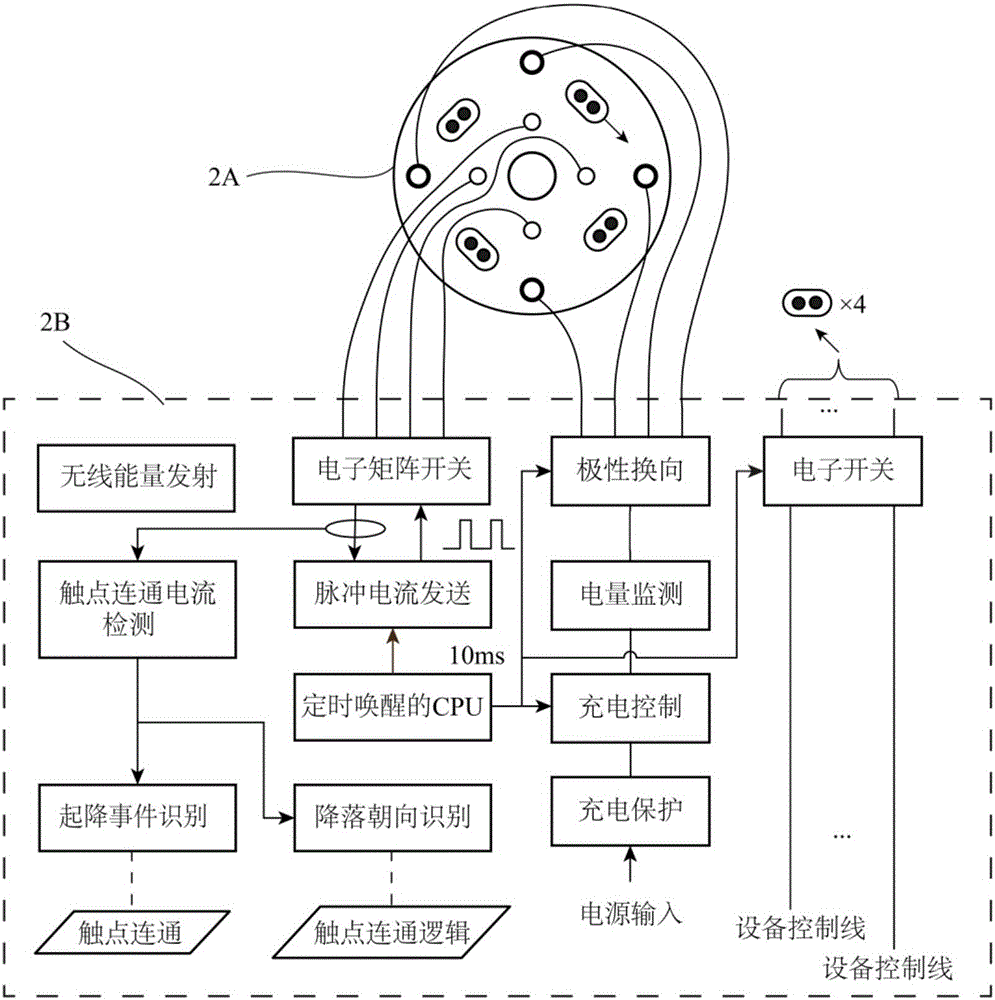

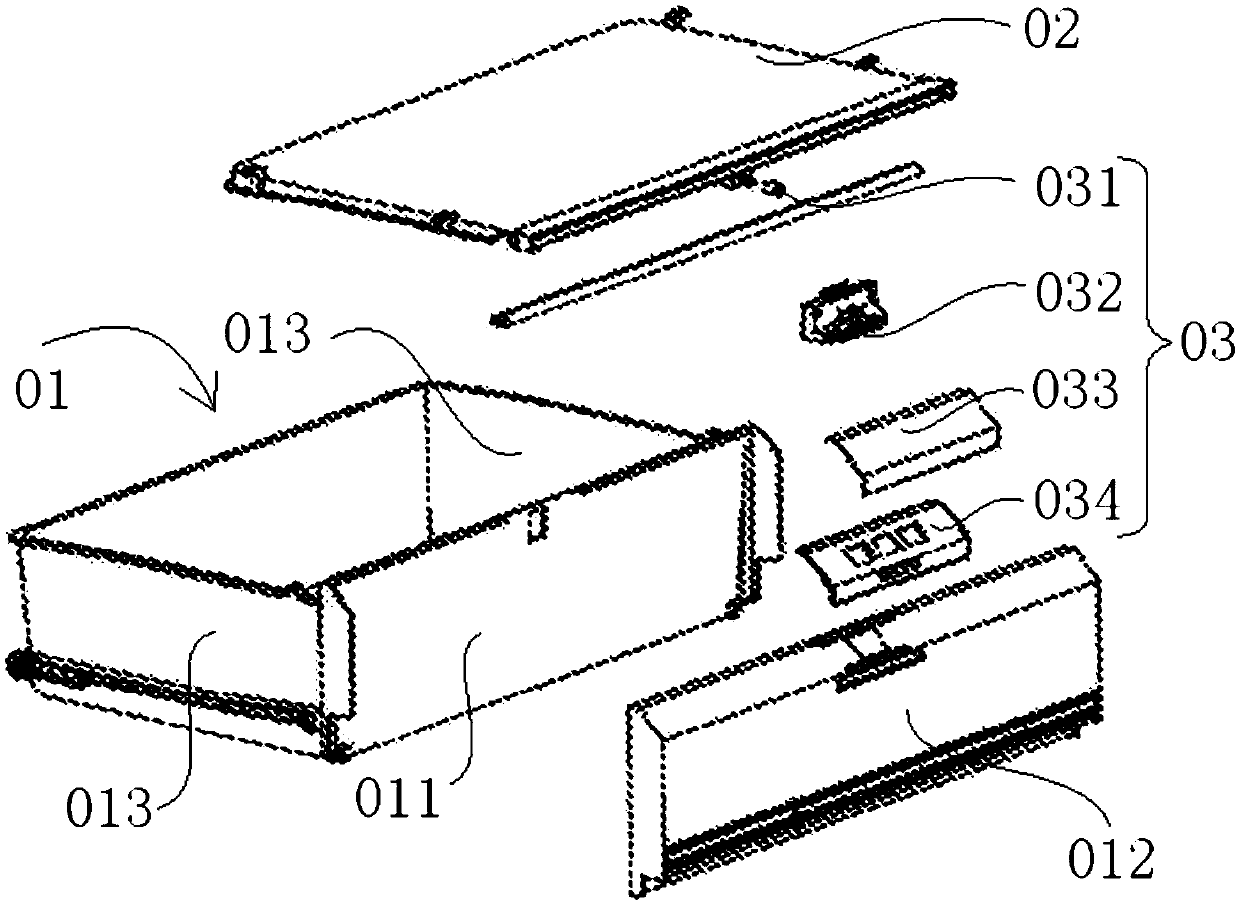

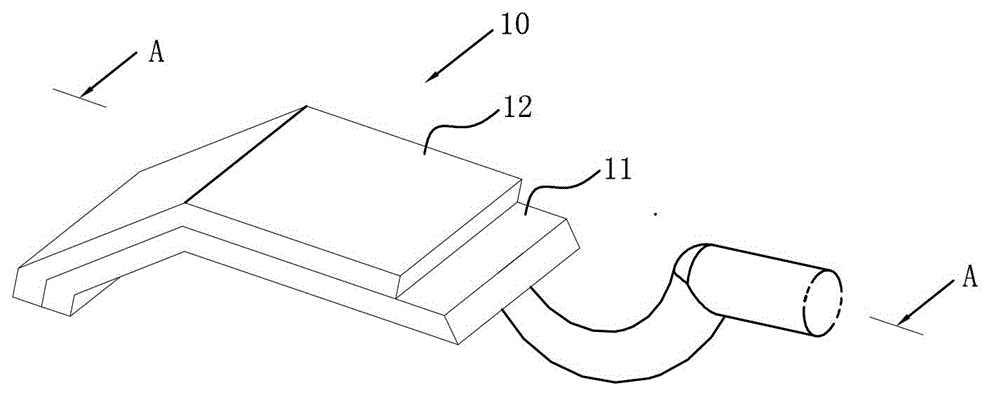

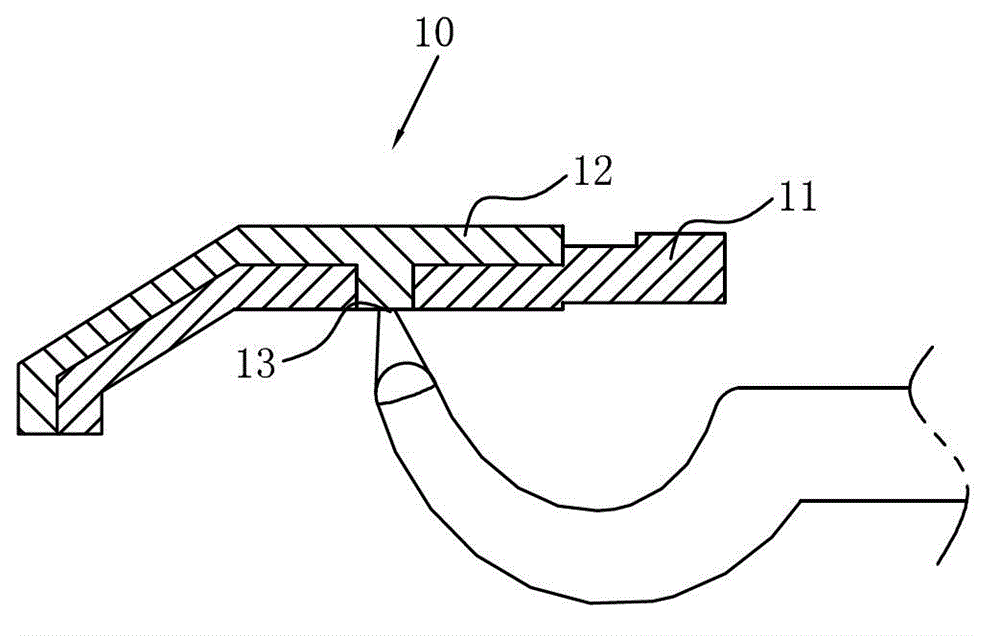

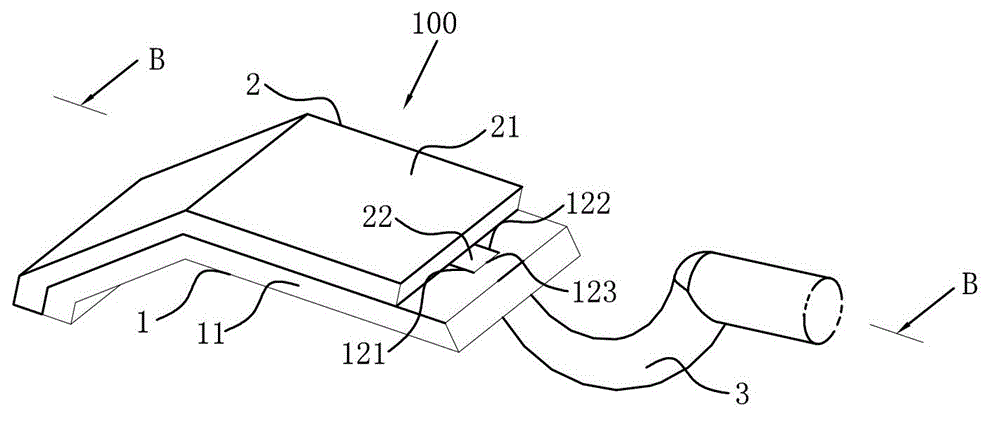

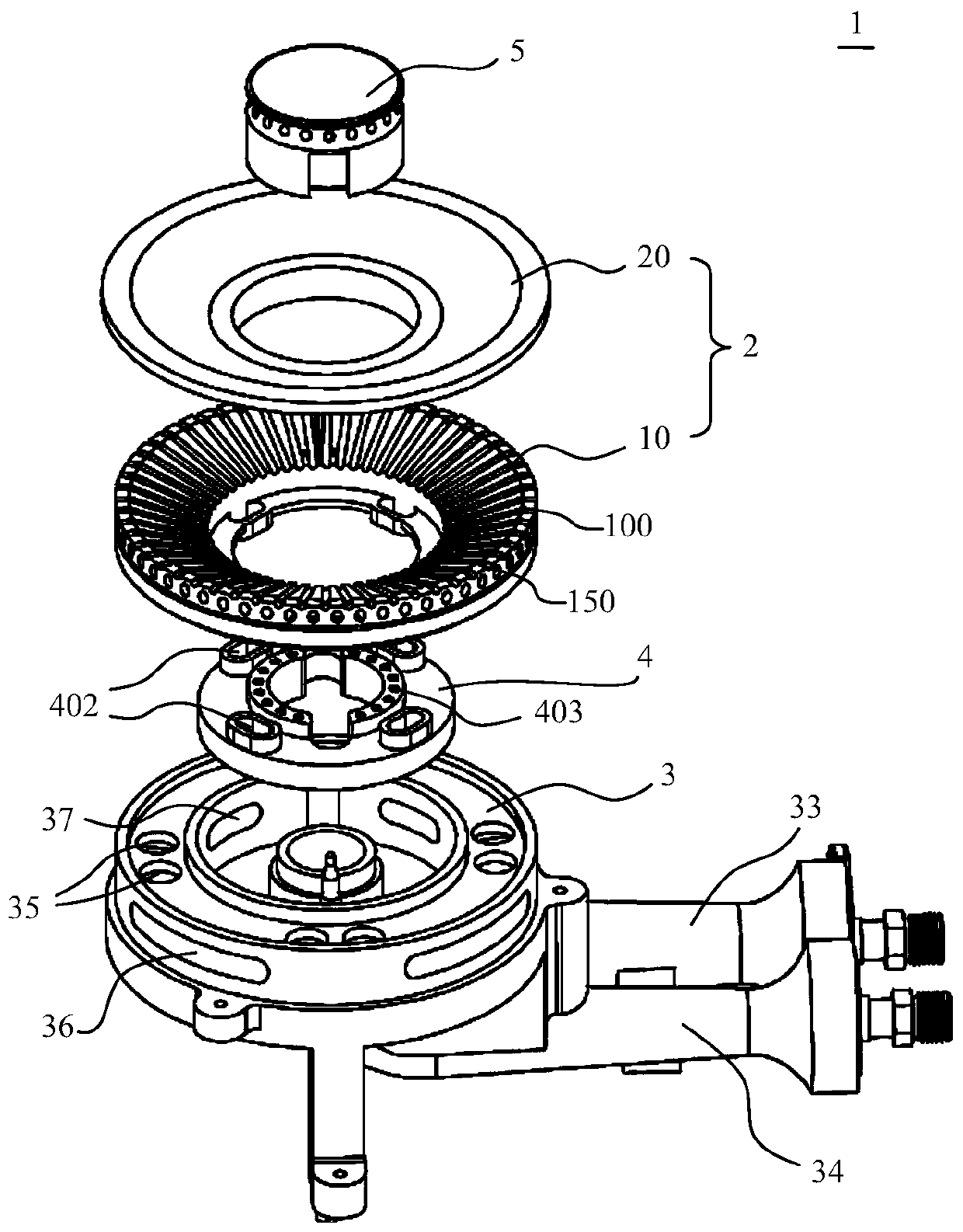

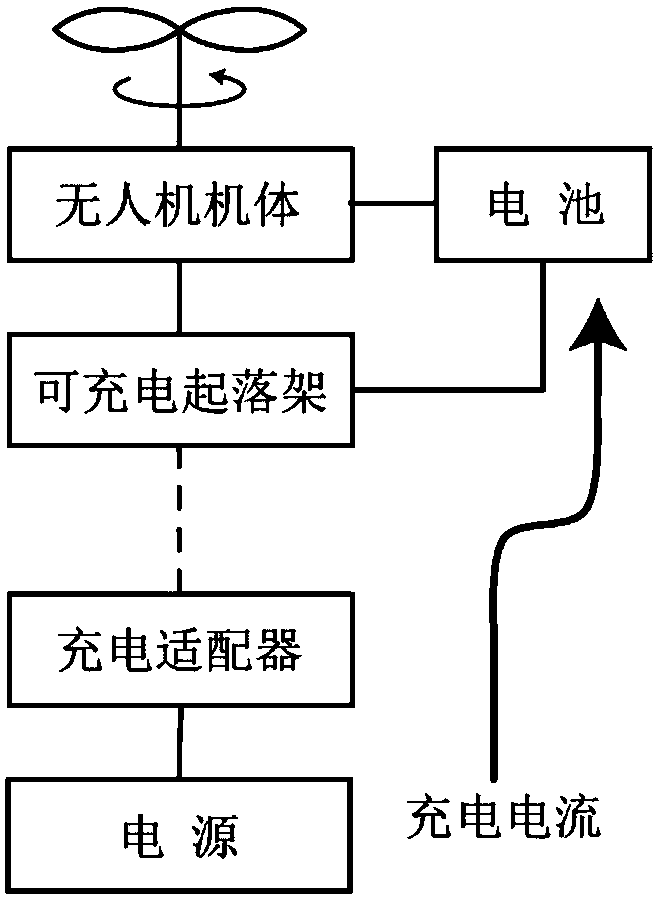

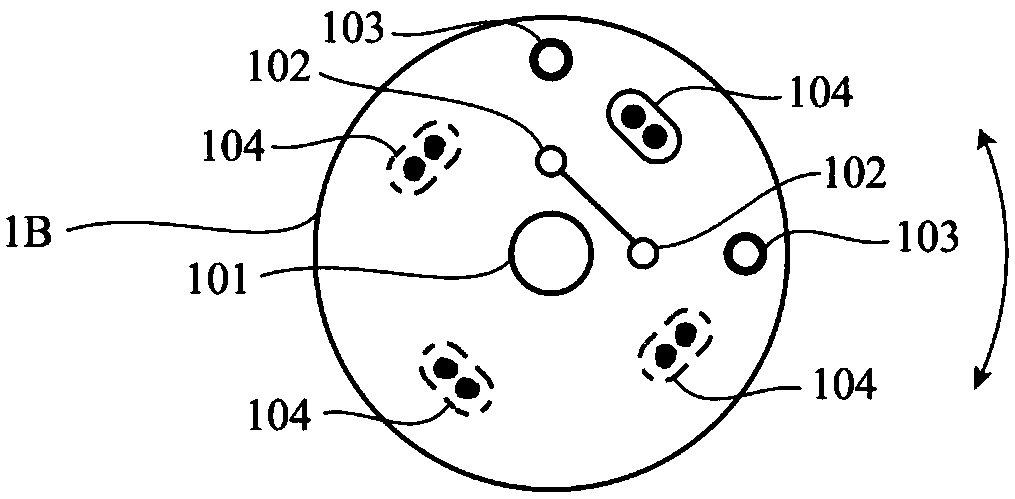

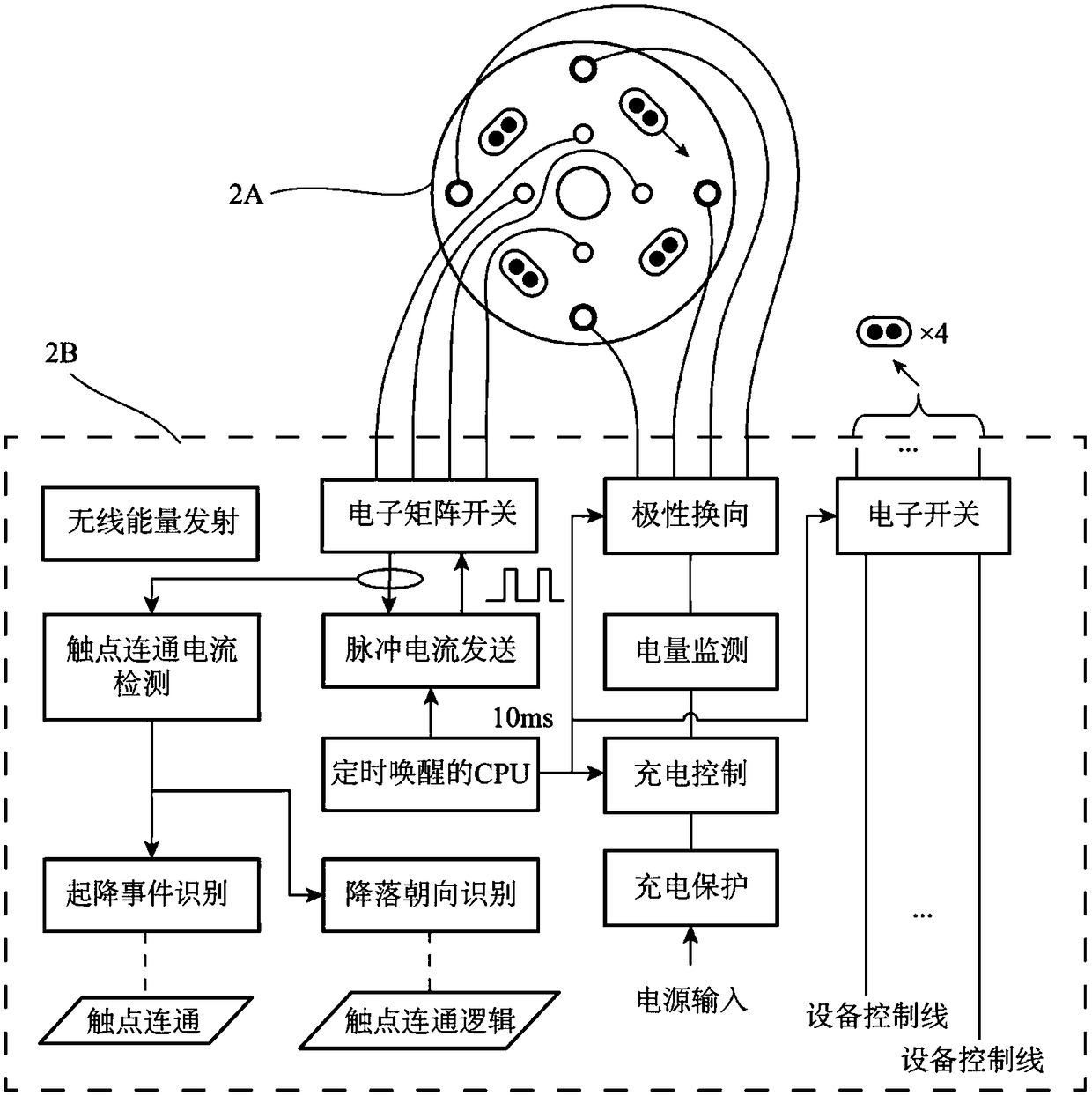

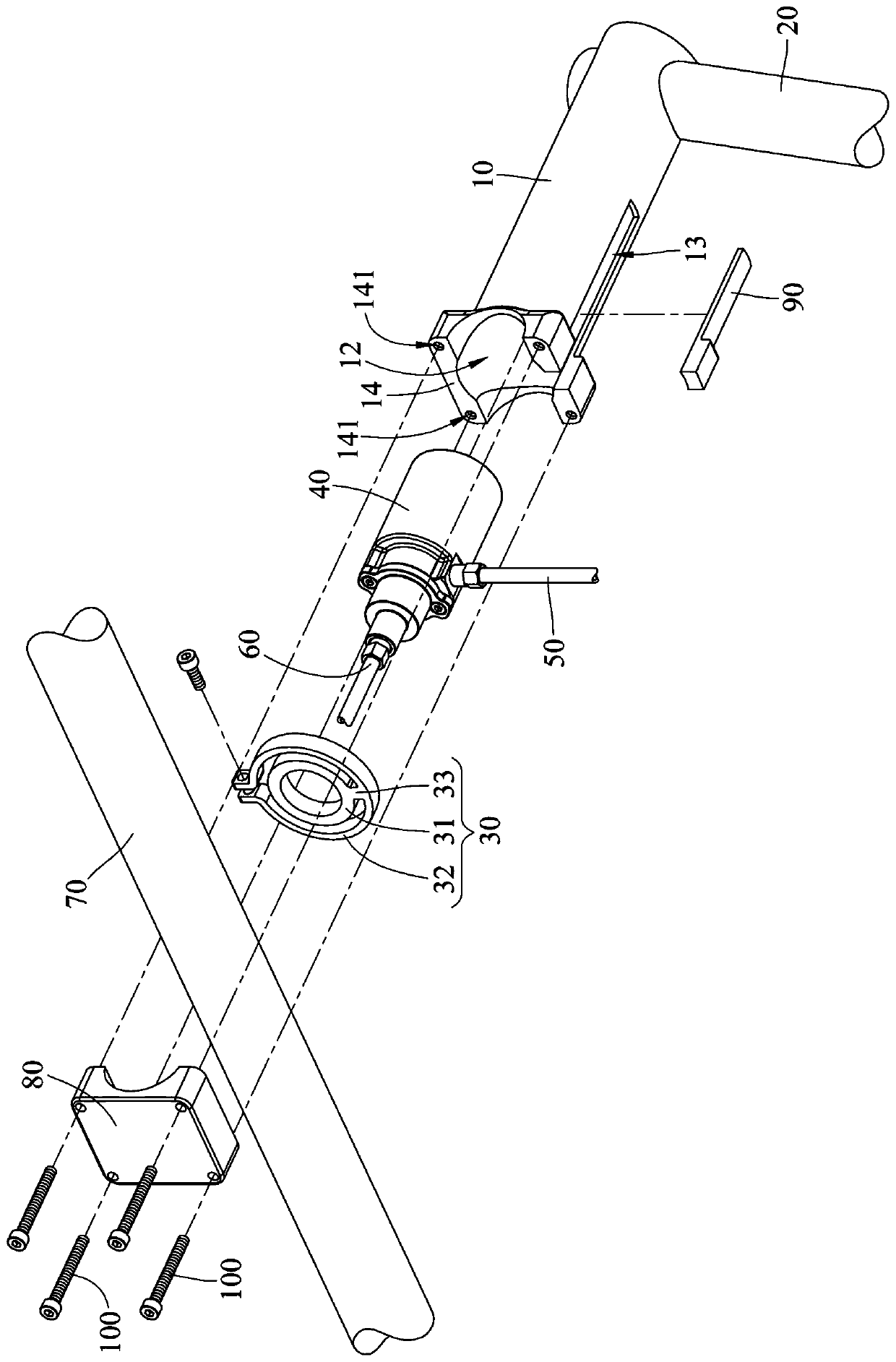

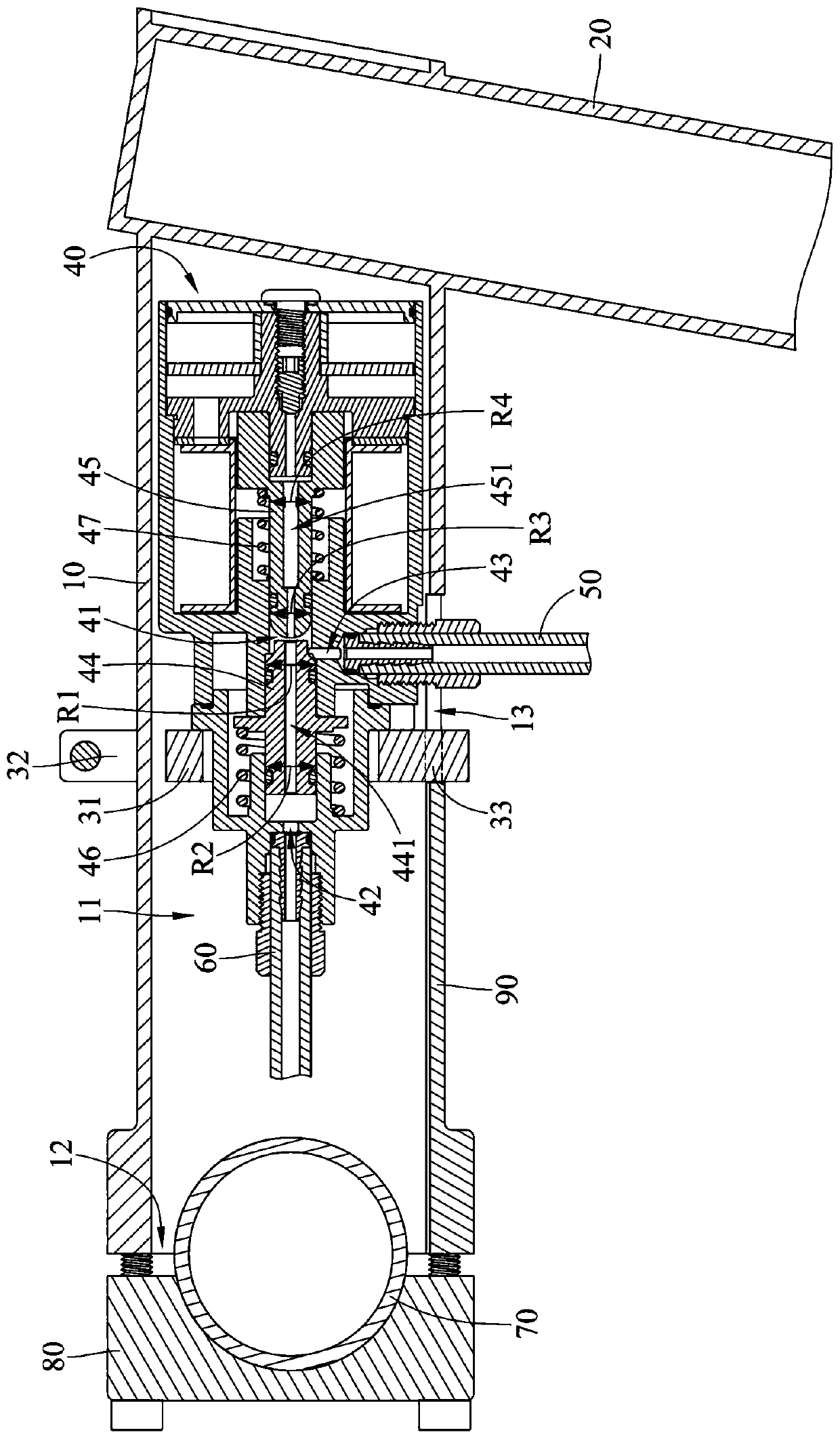

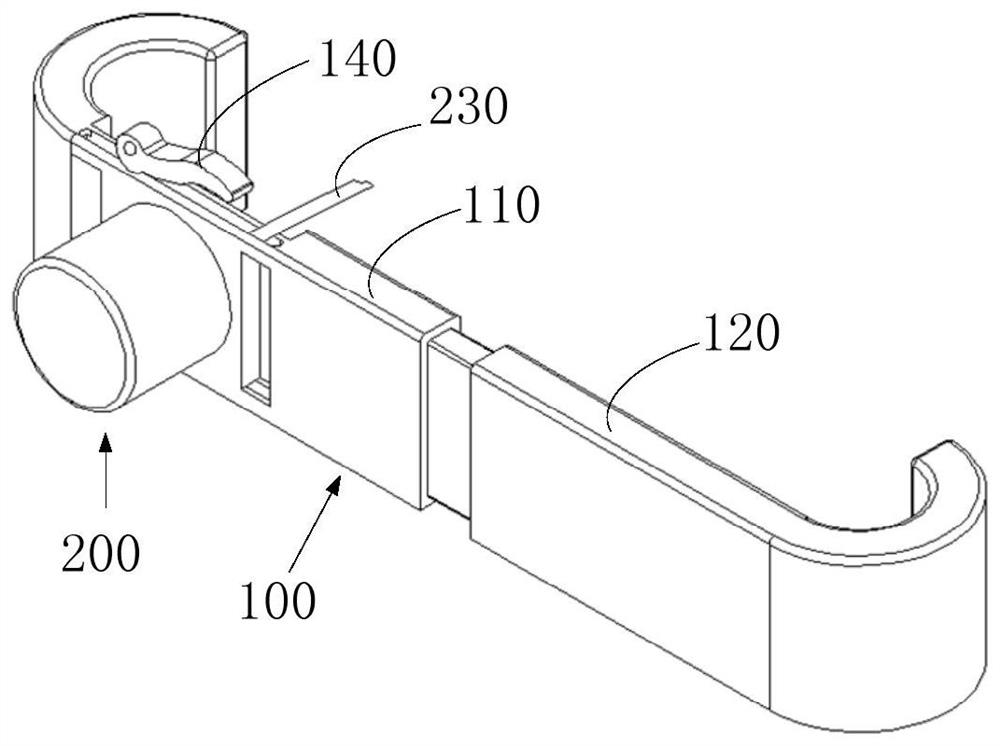

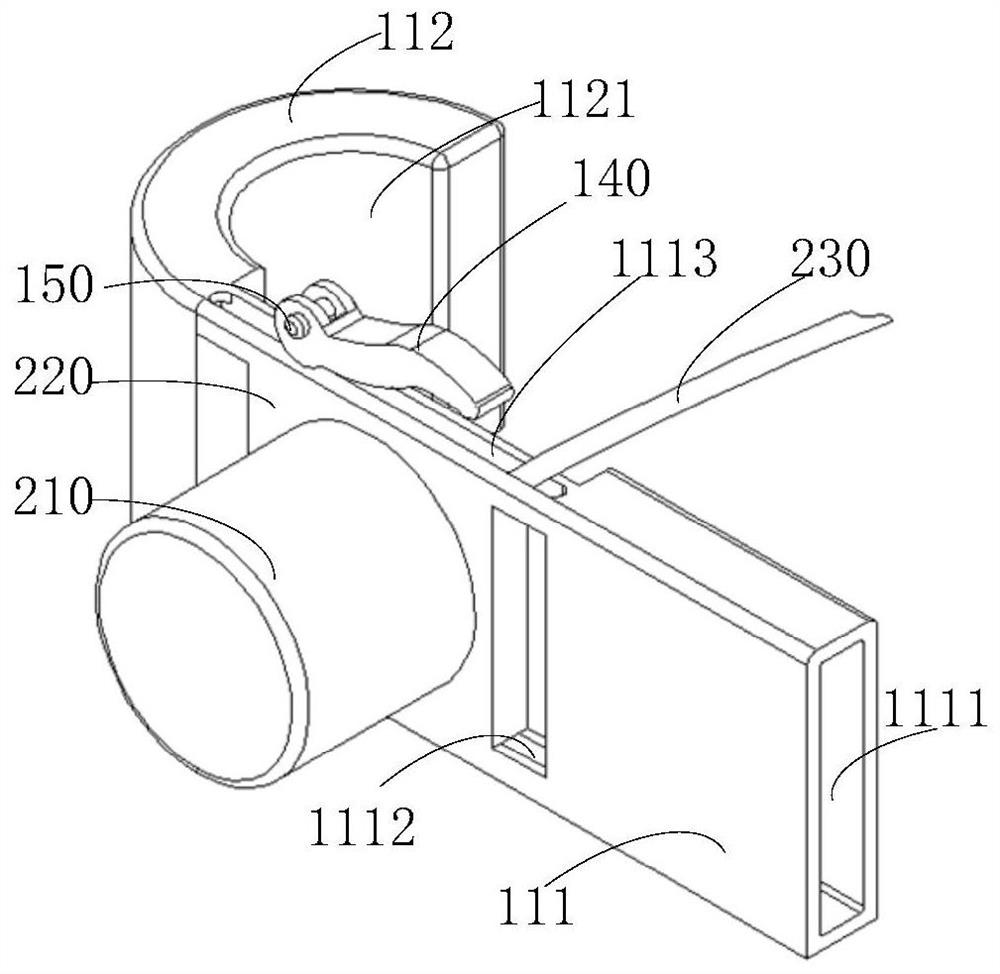

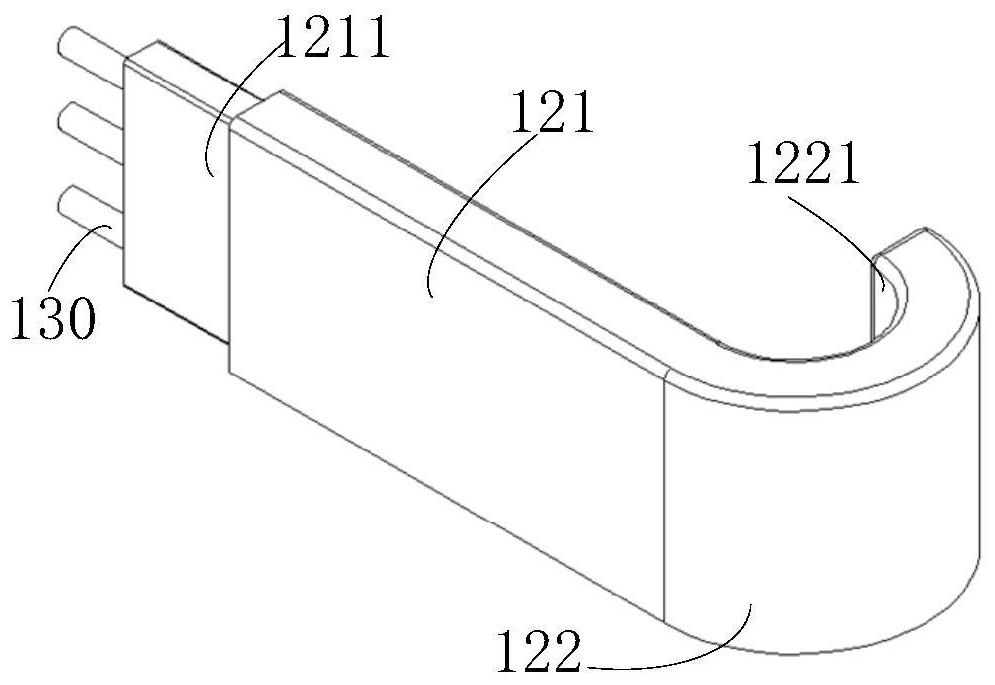

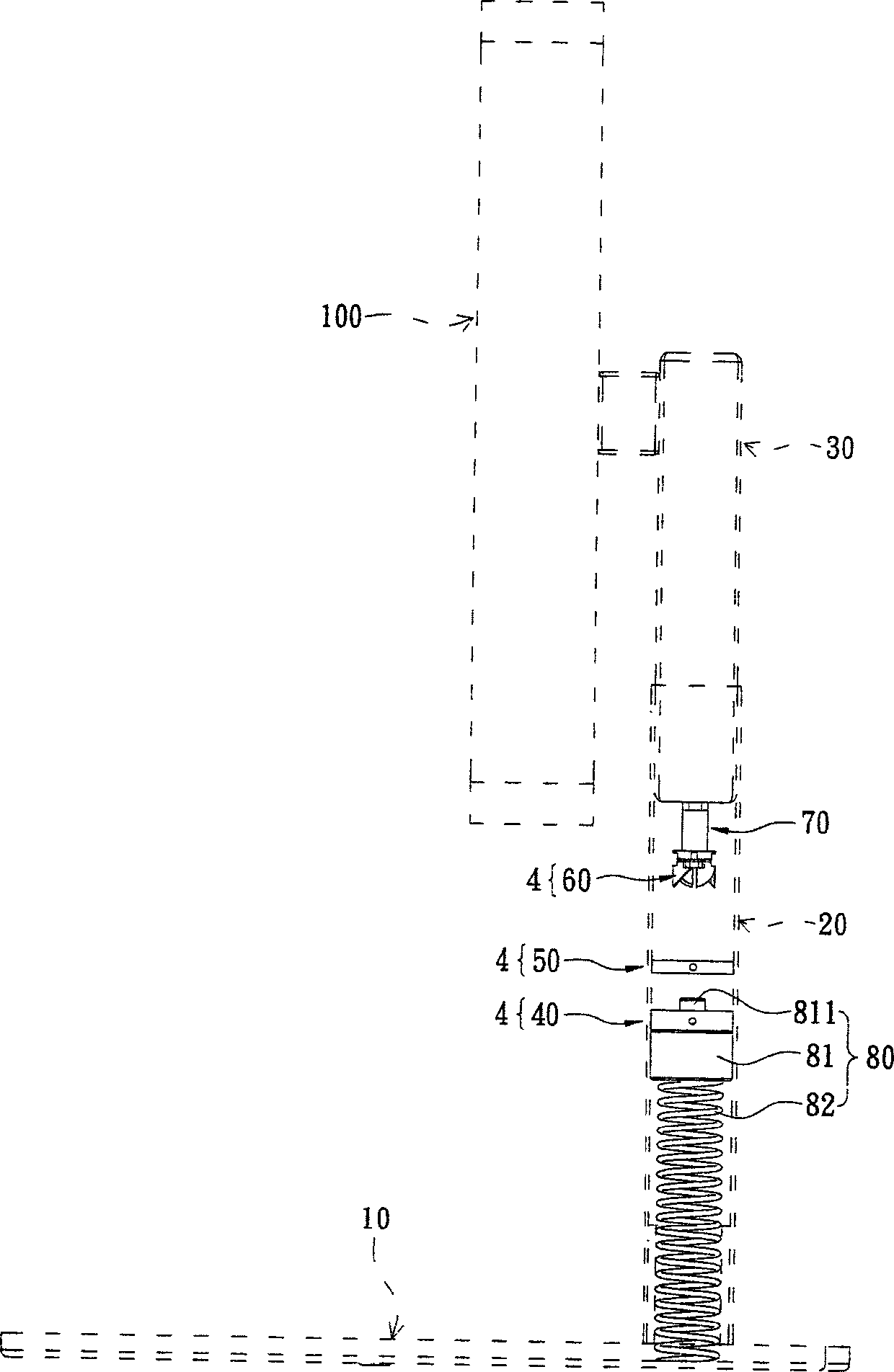

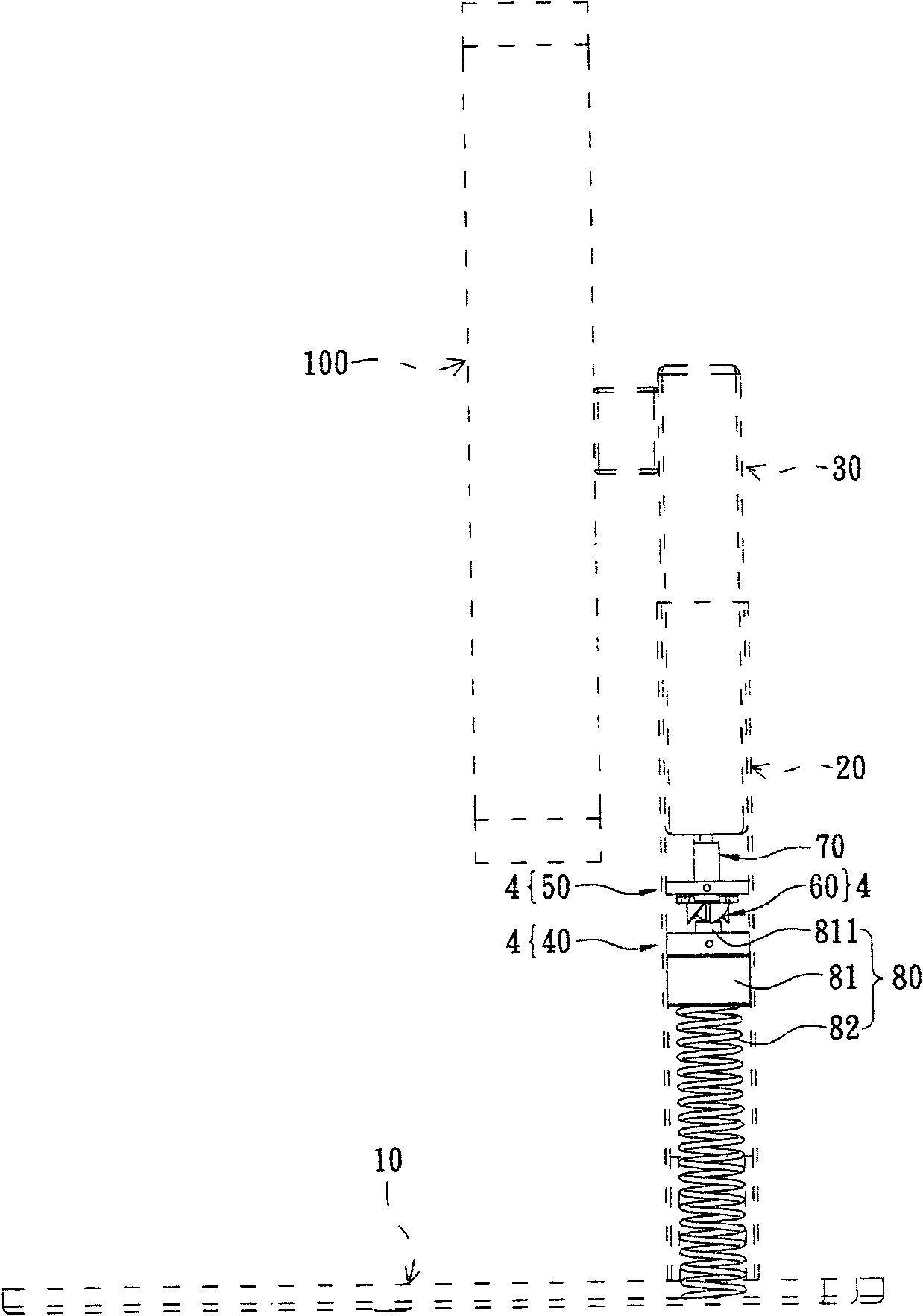

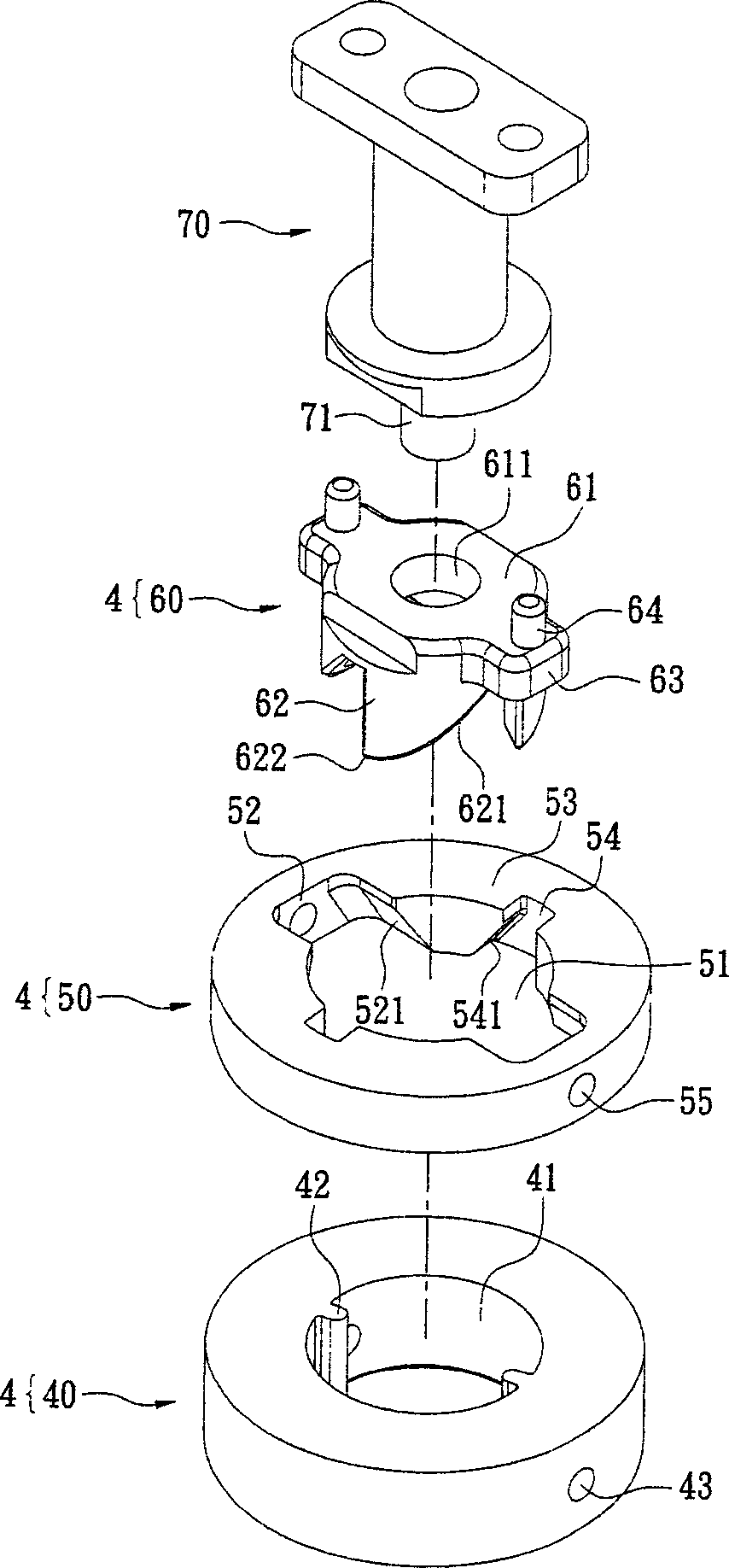

Automatic charging control device and charging method for unmanned aerial vehicle

ActiveCN106058985AAppearance does not affectImprove labor efficiencyCircuit monitoring/indicationSafety/protection battery circuitsAutomatic controlElectrical polarity

The invention belongs to the field of charging control technology, and provides an automatic charging control device and a charging method for an unmanned aerial vehicle. The automatic charging control device comprises a rechargeable undercarriage, a charging adapter and a power supply. The automatic charging control device is mainly and technologically characterized in that the undercarriage with a charging function is utilized; an electromechanical connector with polarity adaption capability is utilized; and through automatic control of a charging control board, an in-position charging technical solution for the battery of the unmanned aerial vehicle is realized. The automatic charging control device and the charging method can be widely applied on an unmanned aerial vehicle landing device or a charging station.

Owner:青岛海盾雷达声纳工程技术有限公司

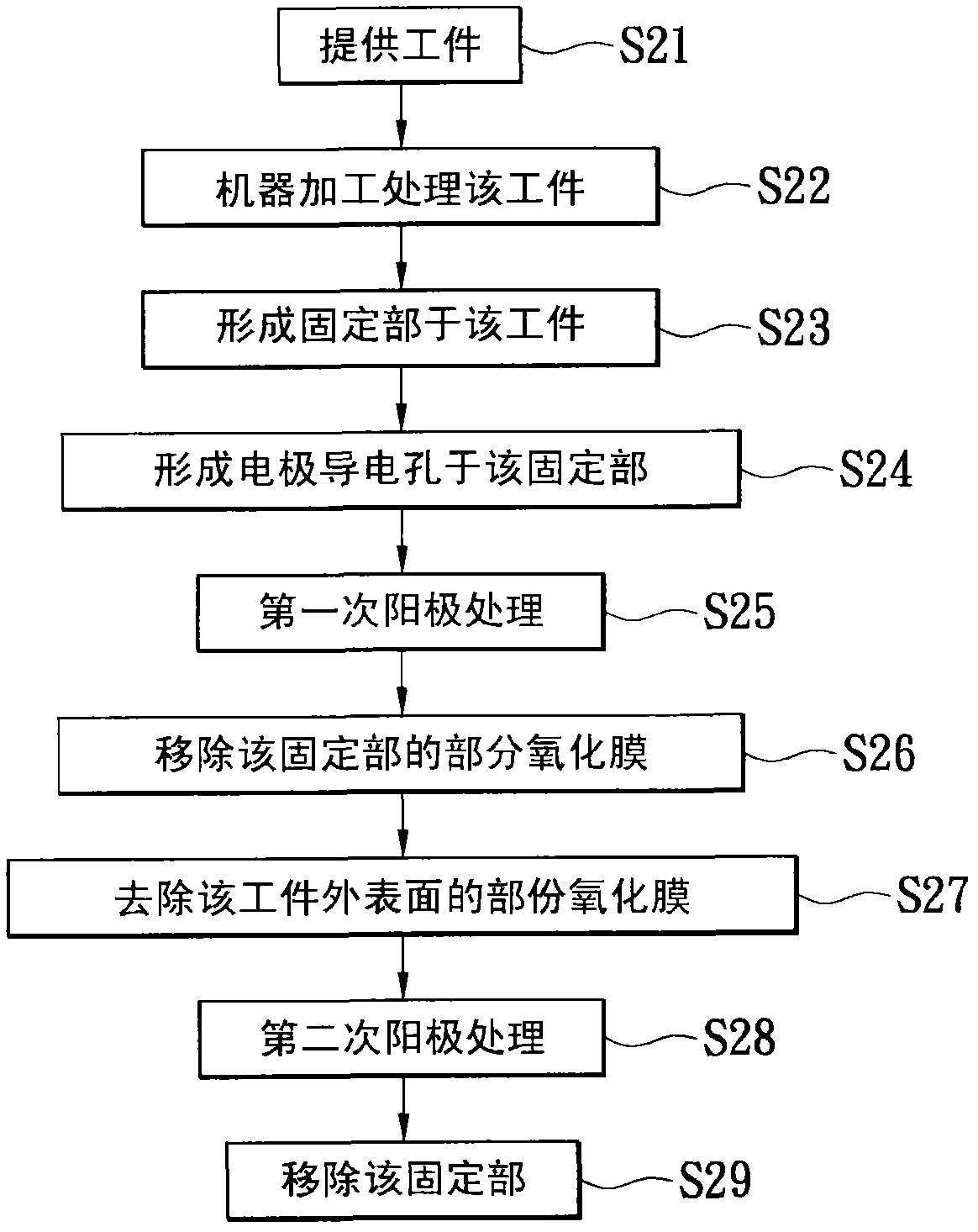

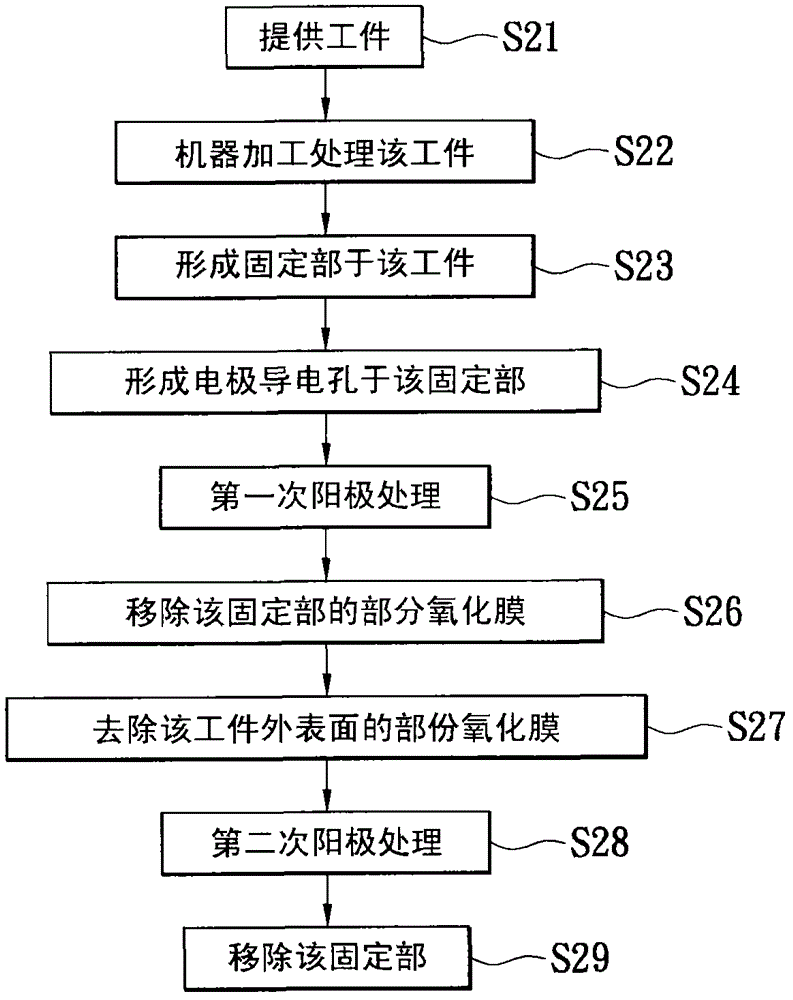

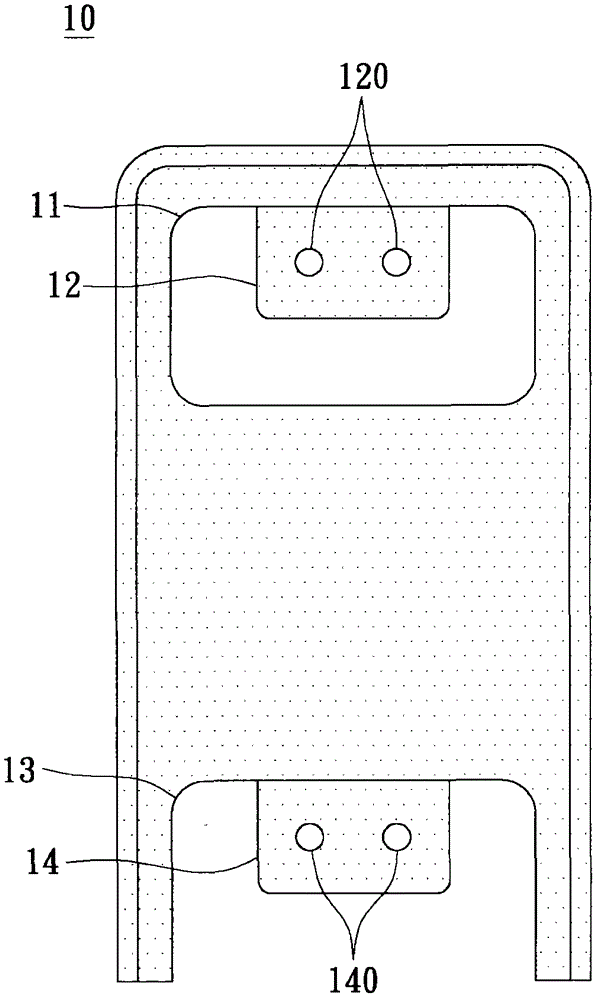

Treatment method for forming composite surface

ActiveCN103255461ANo risk of damageAppearance does not affectSurface reaction electrolytic coatingAnodizingMetal

The invention relates to a treatment method for forming a composite surface. The method comprises the following steps: providing a workpiece, wherein the workpiece is an aluminum-containing metal shell, and comprises an outer surface and an inner surface; carrying out a machine processing treatment on the workpiece; forming a fixation part on the inner surface of the workpiece, forming at least an electrode conduction hole on the fixation part, carrying out a primary anode treatment on the workpiece, forming an oxidation film with a first color on the surface of the workpiece, adopting the machine processing manner to remove part of the oxidation film on the fixation part, and removing part of the oxidation film on the outer surface of the workpiece; carrying out a secondary anode treatment on the workpiece, and forming an oxidation film with a second color on a position on the outer surface of the workpiece, wherein the oxidation film is removed from the position on the outer surface of the workpiece; and removing the fixation part. With the treatment method, a surface of a metal workpiece can obtain oxidation films with different colors.

Owner:CATCHER TECH

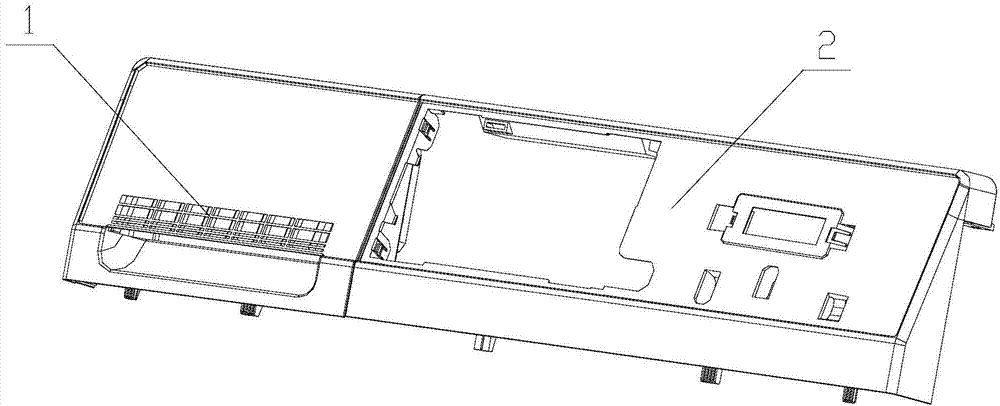

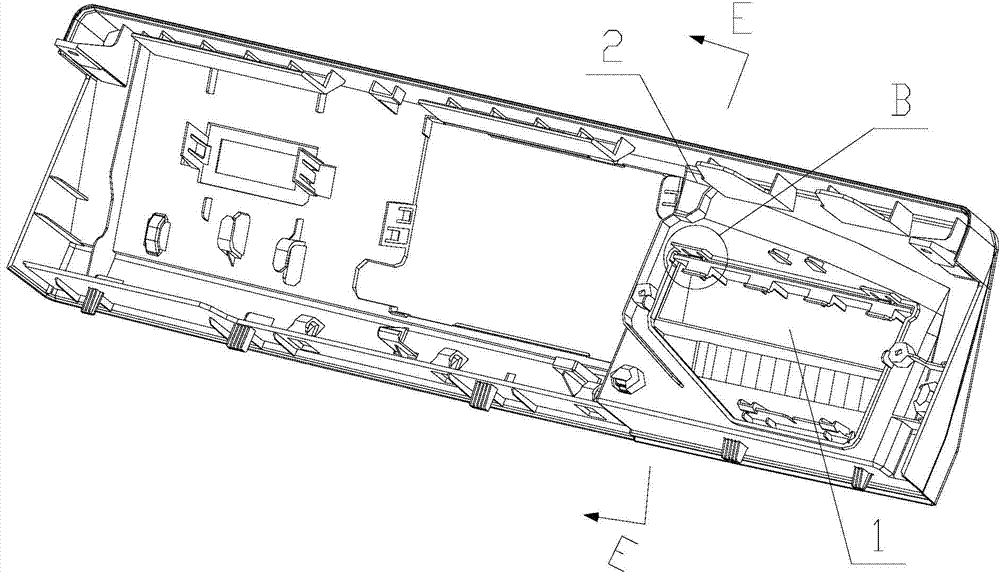

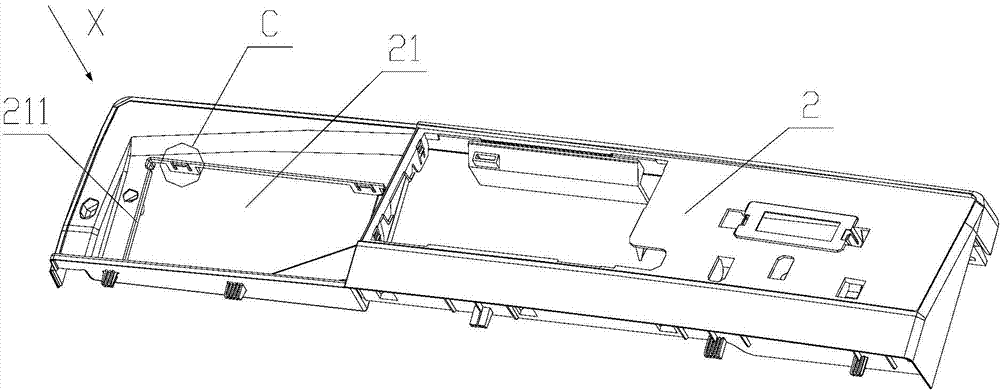

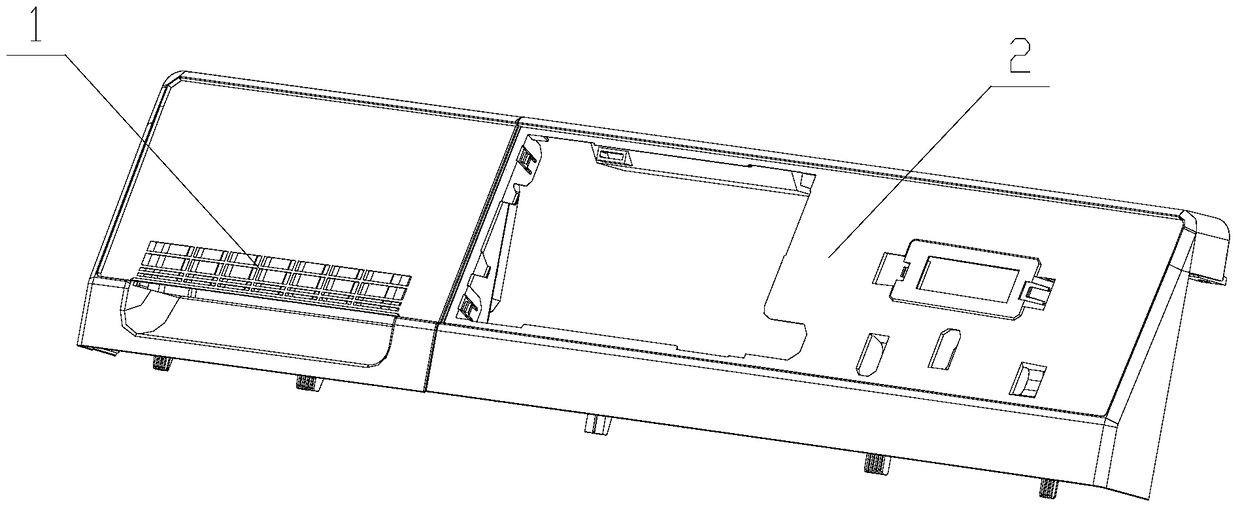

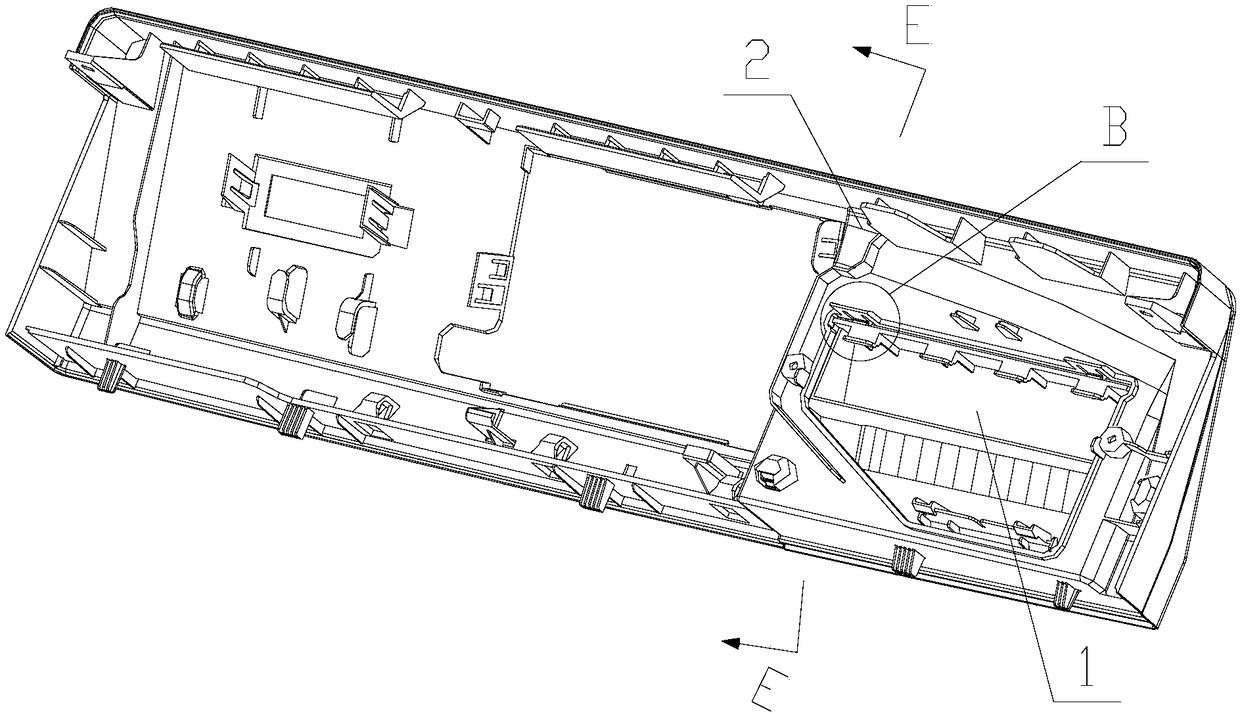

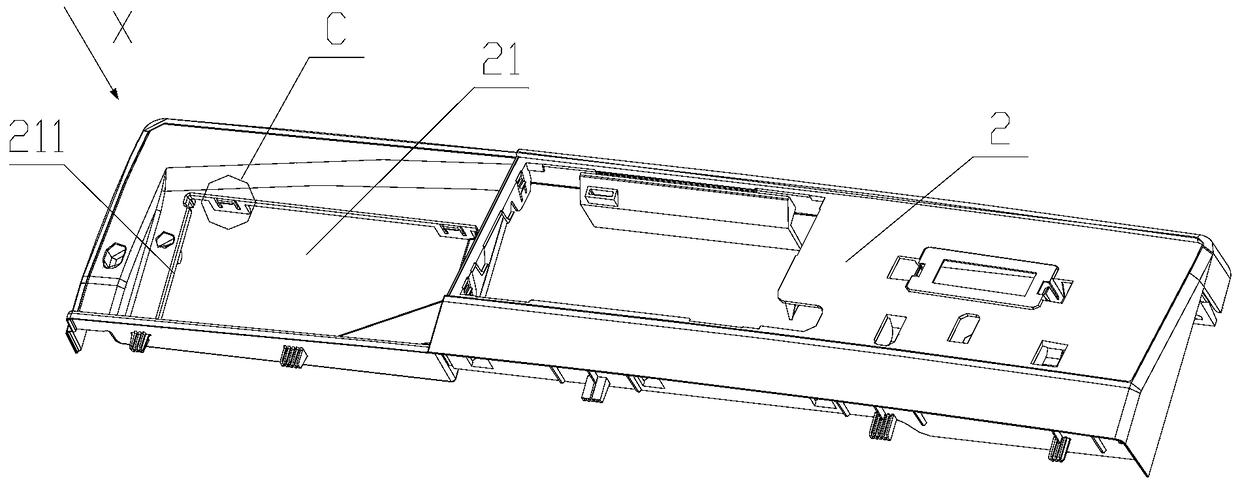

Locking mechanism for roller washing machine distributor

ActiveCN104775279AGood lookingAppearance does not affectOther washing machinesTextiles and paperLocking mechanismEngineering

The invention discloses a locking mechanism for a roller washing machine distributor, and belongs to the field of washing machines. The locking mechanism comprises a distributor handle and a main control board, wherein the main control board is provided with an assembling hole for mounting the distributor handle; the distributor handle is in splicing fit with the main control board through the assembling hole; a clamping hook is arranged inside the main control board; the distributor handle is provided with an inverted buckle; the clamping hook is clamped with the inverted buckle; the clamping hook comprises an elastic cantilever and a clamping table; the clamping table is fixed at the free end of the cantilever; the fixed end of the elastic cantilever is fixed on the inner edge of the side wall of the assembling hole. The locking mechanism provided by the invention can be clamped stably, the distributor handle is simple and attractive in appearance, and the visual feel of a user is good.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

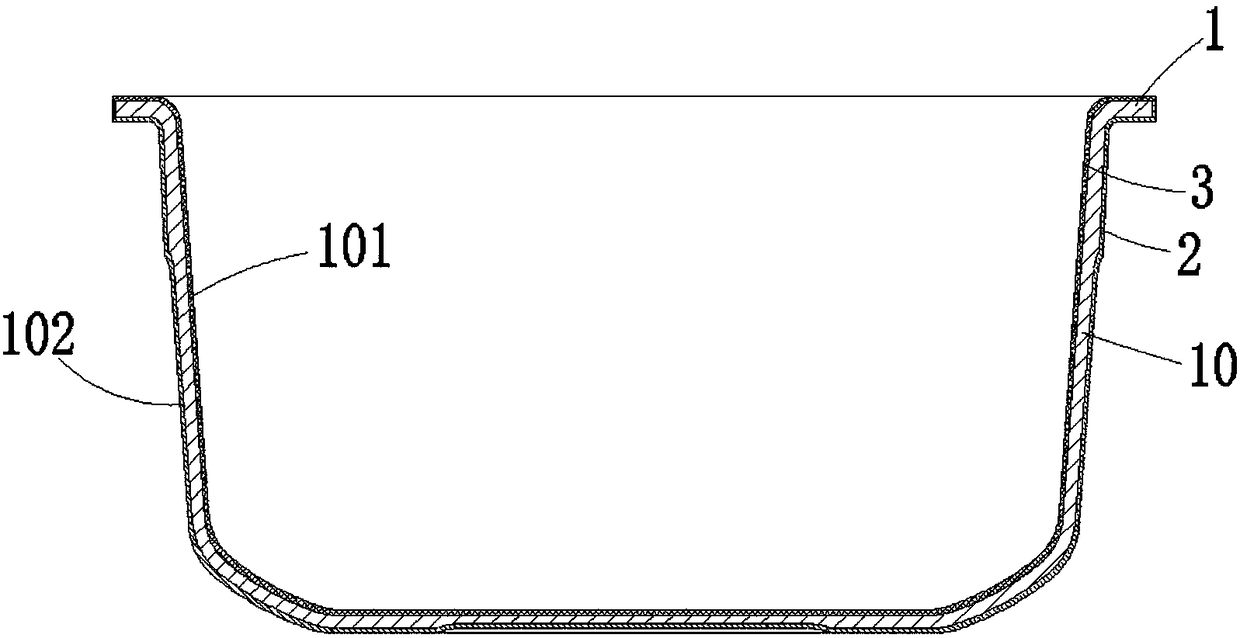

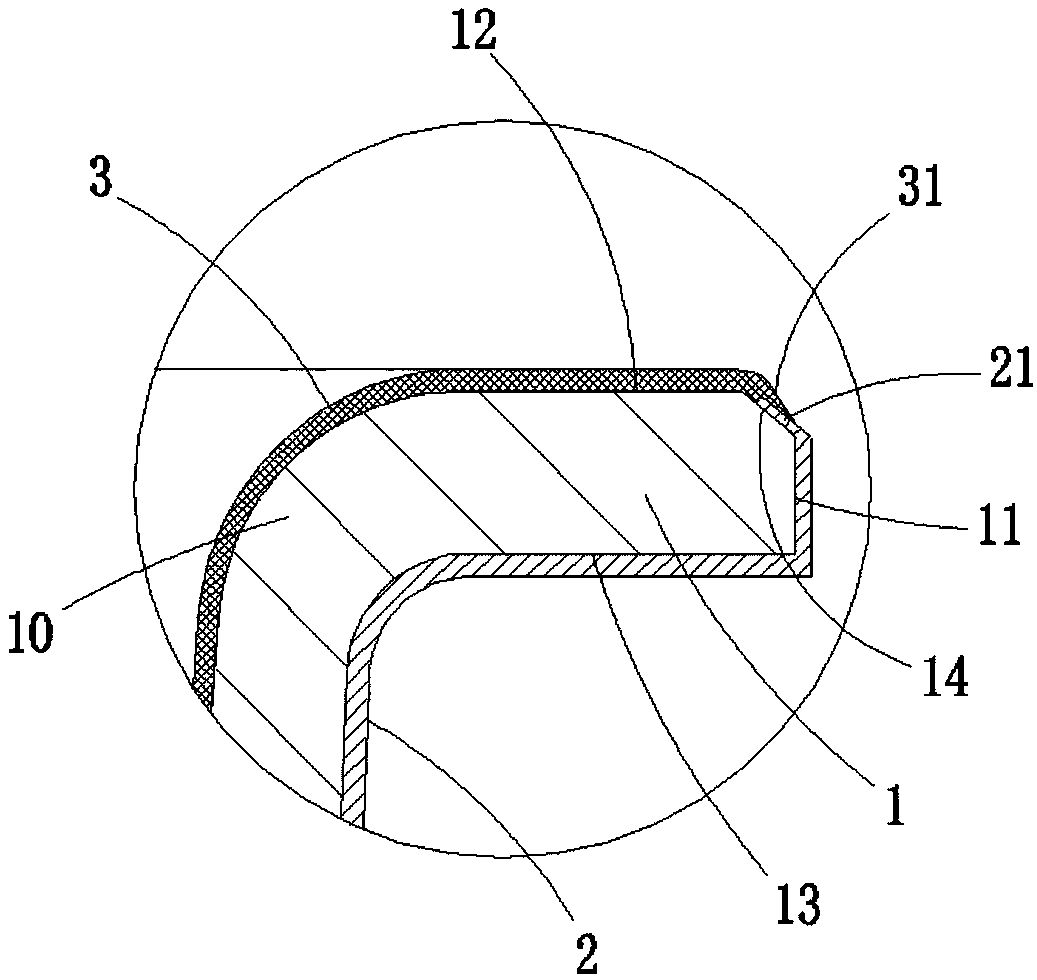

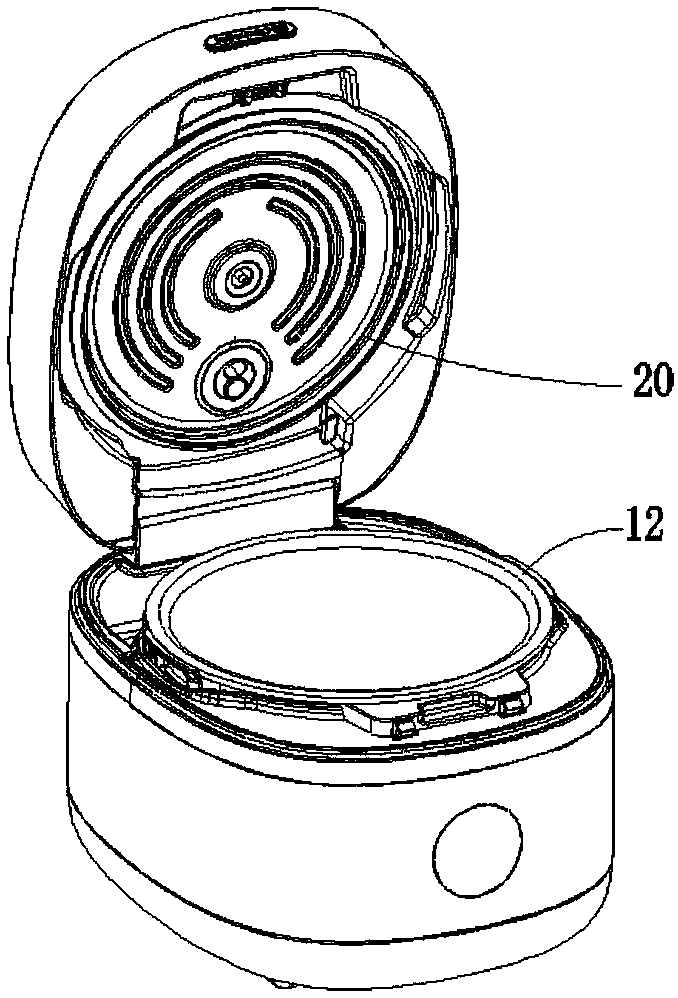

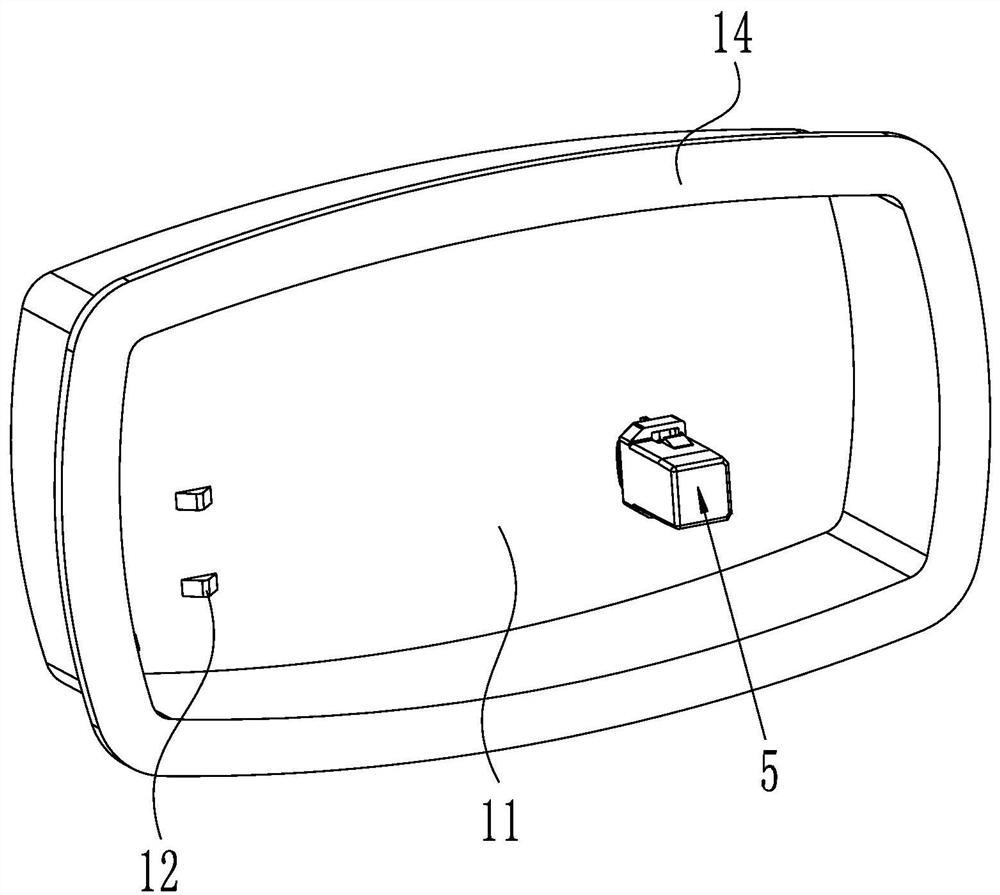

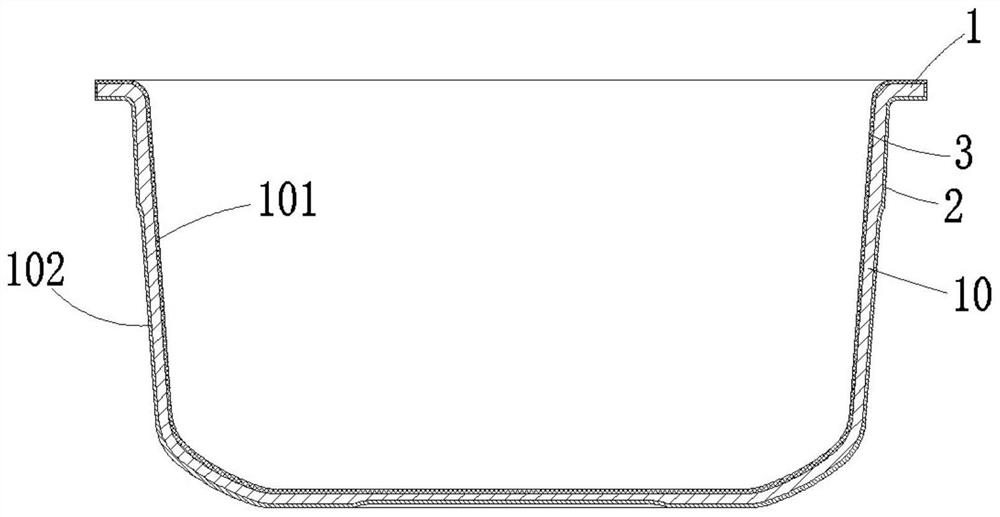

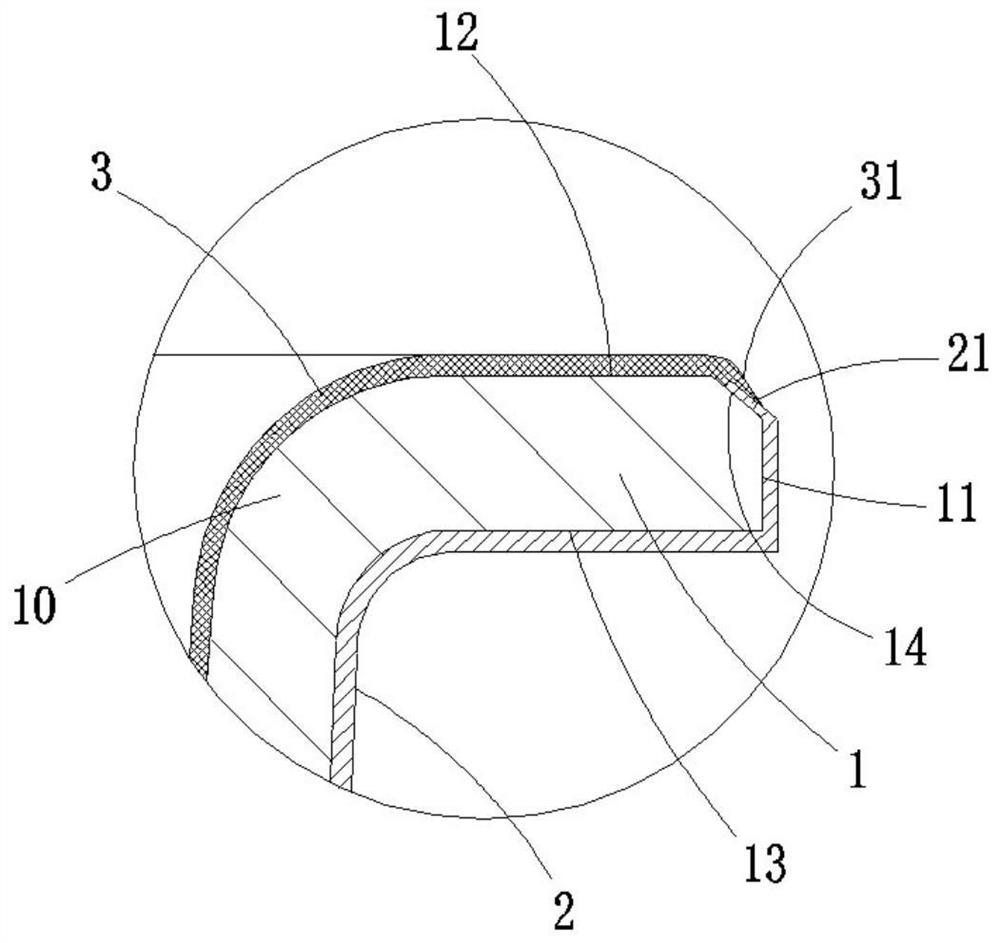

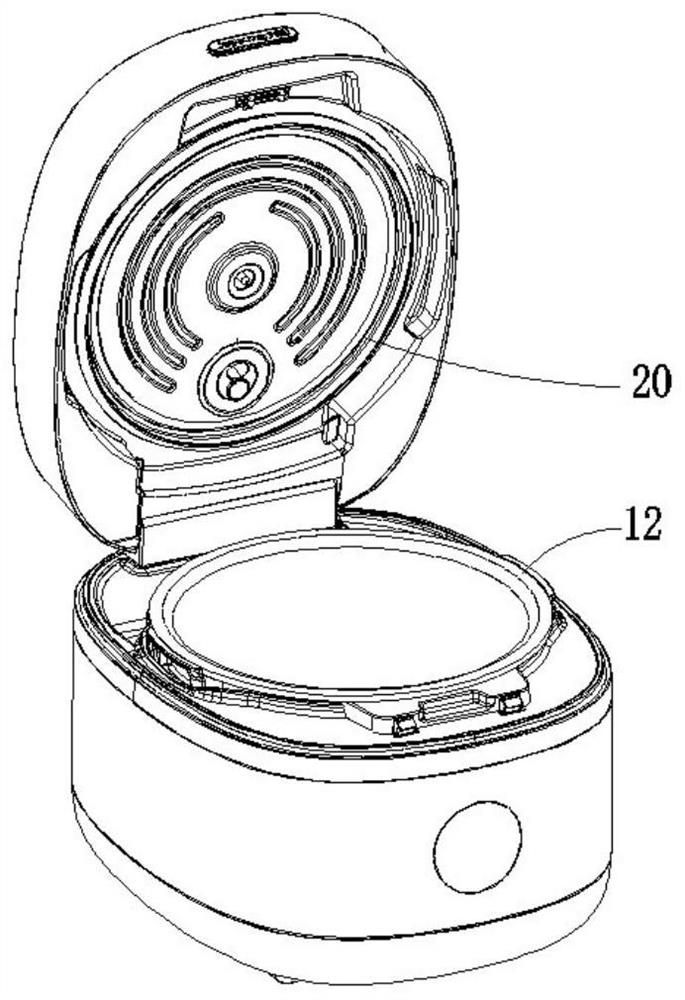

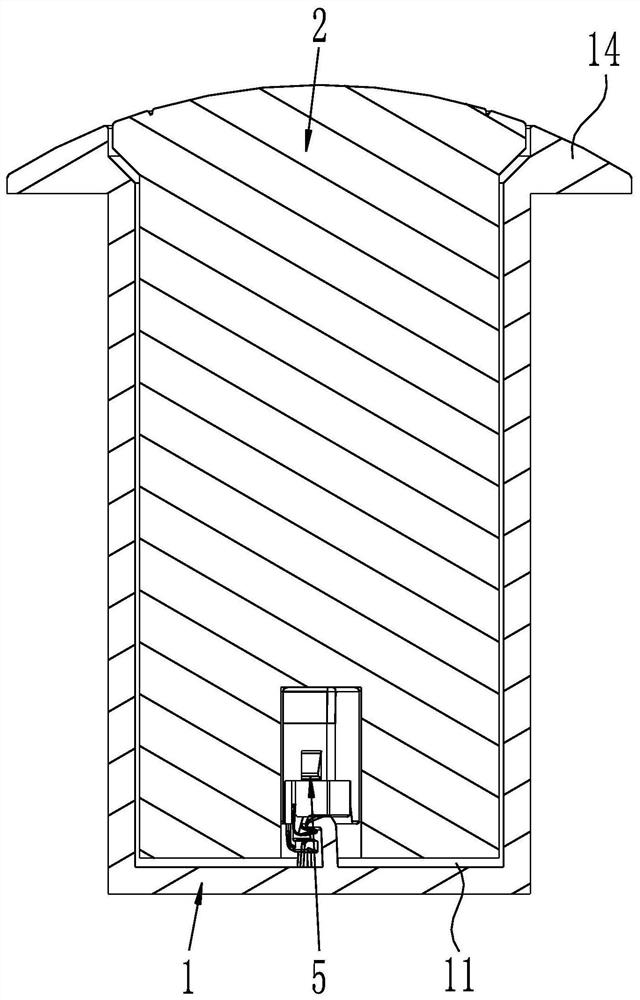

Enamel inner container for cooking utensil

ActiveCN108158387AGuaranteed non-stickImprove corrosion resistanceCooking-vessel materialsCooking vessel constructionsMaterials scienceFlange

The invention provides an enamel inner container for a cooking utensil. The enamel inner container comprises a cast iron container body, an enamel glaze layer is sintered on the outer surface of the cast iron container body, a non-stick coating is sprayed to the inner surface of the cast iron container body, an opening of the cast iron container body is provided with an outward radial flange, theenamel glaze layer and the non-stick coating both extend to the flange, corners are formed between the top face of the flange and the outer end face of the flange and between the bottom face of the flange and the outer end face of the flange respectively, and the joint between the enamel glaze layer and the non-stick coating is located at one corner. The inner and outer surfaces of the inner container are provided with the non-stick coating and the enamel glaze layer respectively, and the container has the advantages of having few flaws, and being attractive in appearance and good in touch.

Owner:JOYOUNG CO LTD

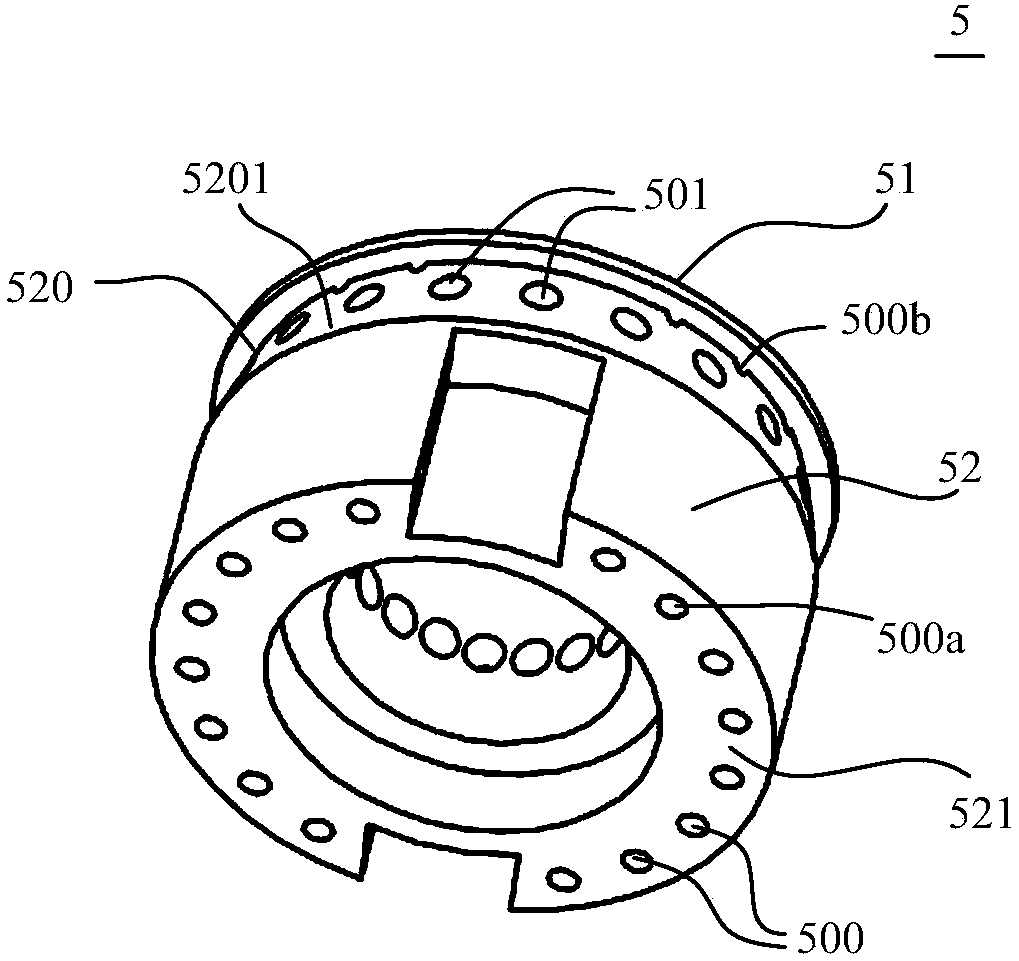

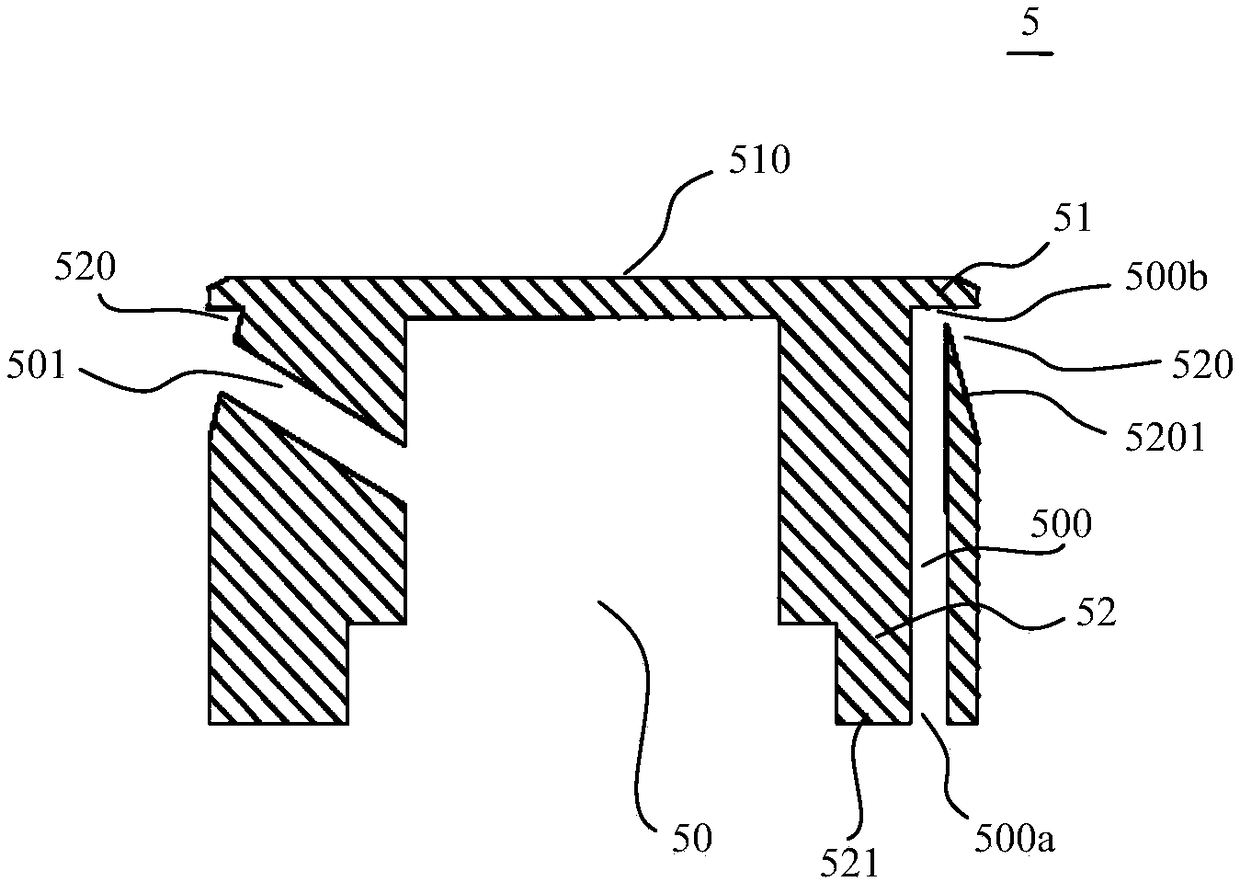

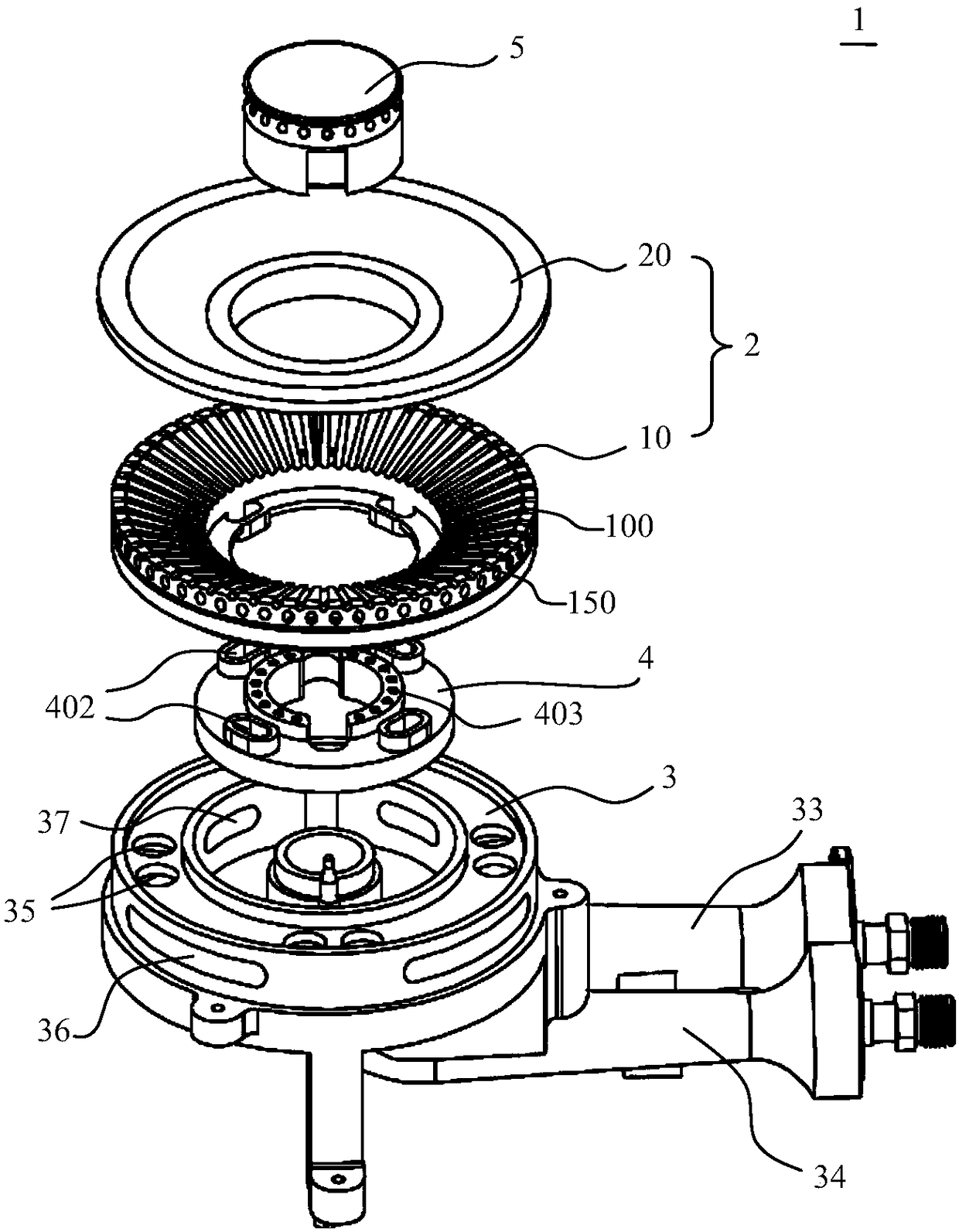

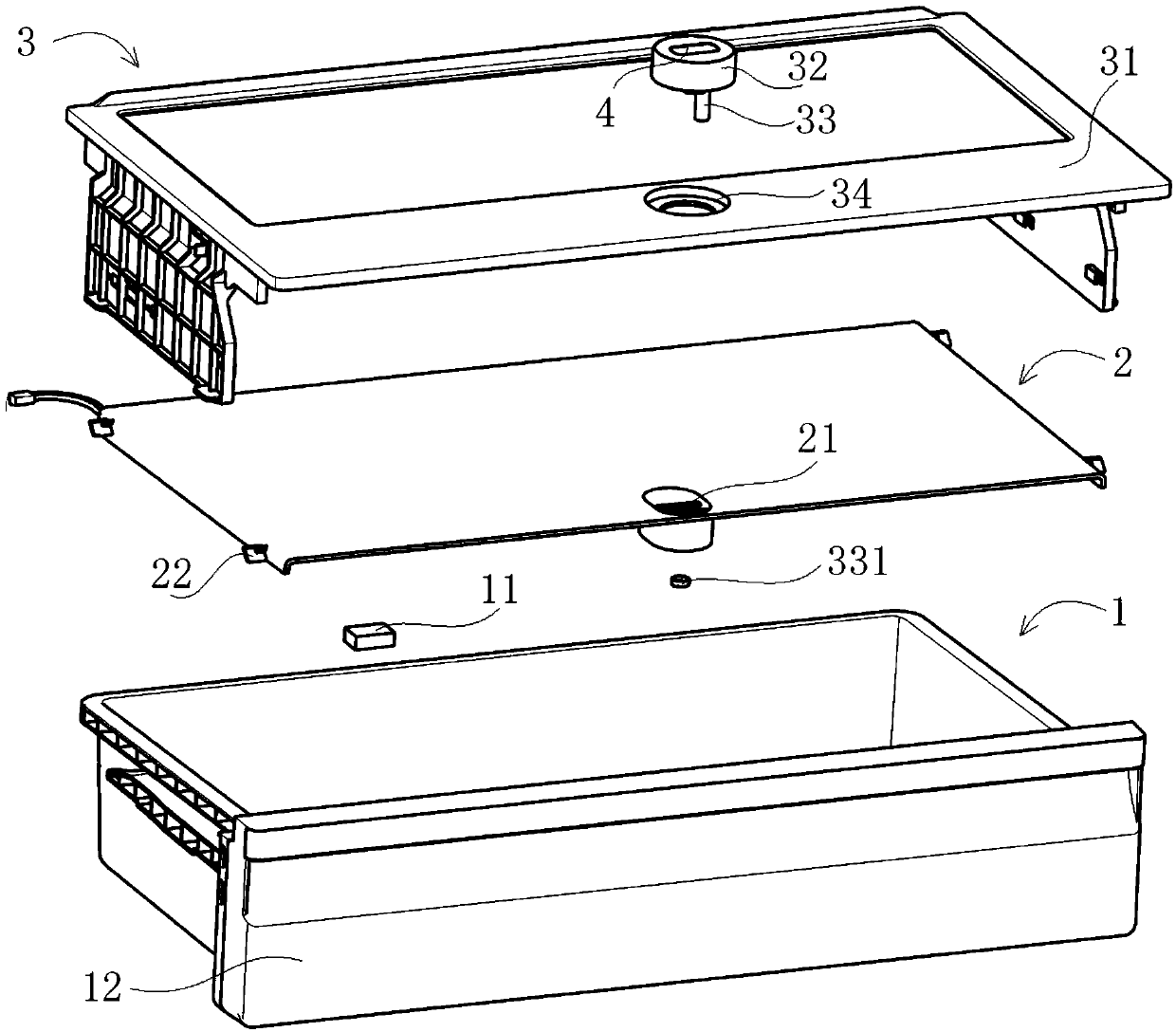

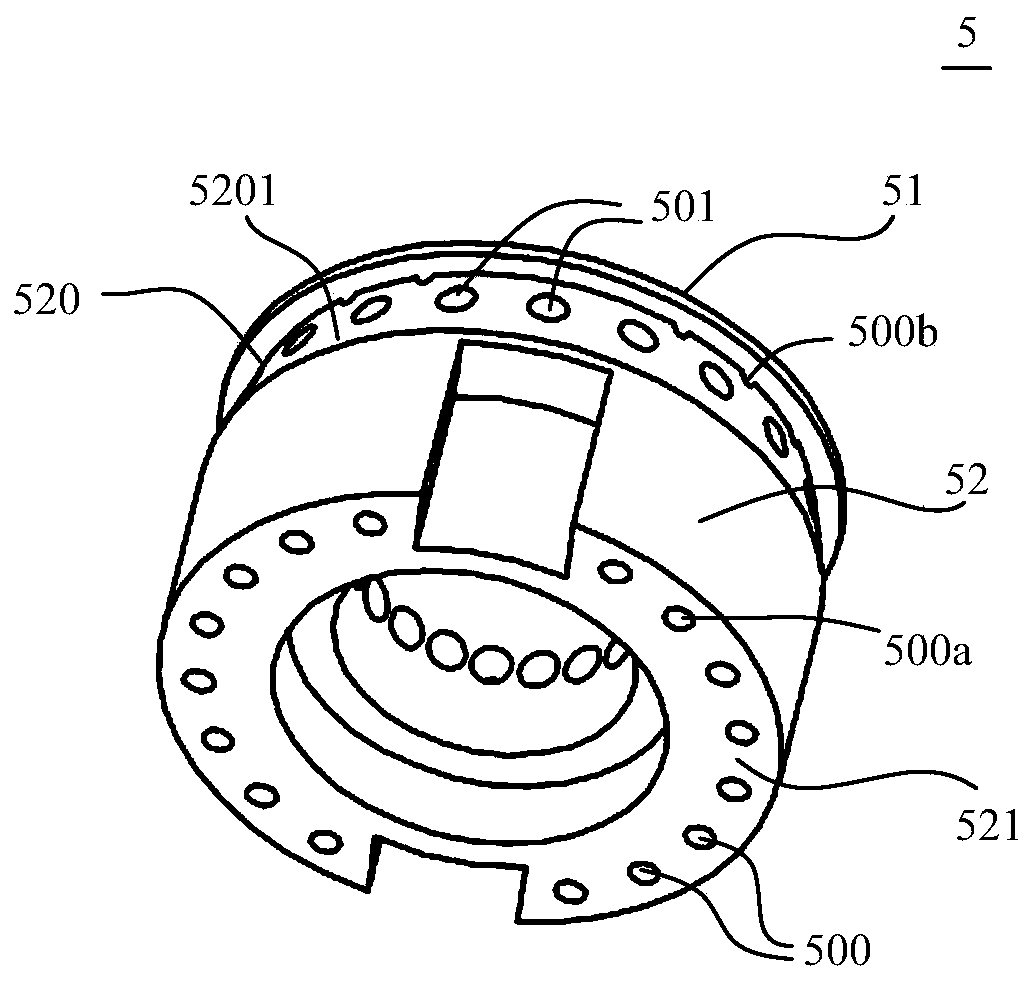

Fire cover of combustor for gas stove, gas stove and combustor of gas stove

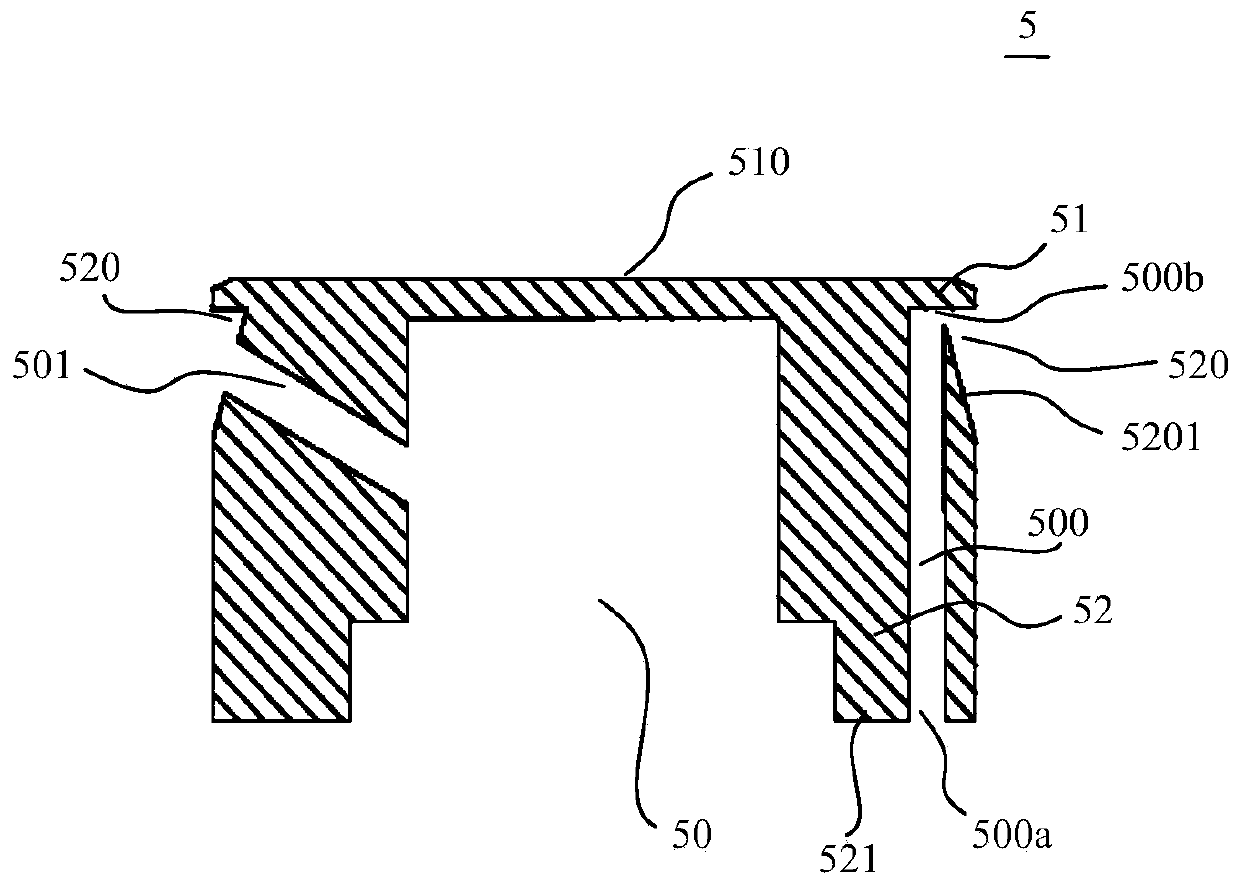

ActiveCN108343958AAppearance does not affectAppearance effectGaseous fuel burnerEngineeringGas cooking stove

The invention discloses a fire cover of a combustor for a gas stove, the gas stove and the combustor of the gas stove. The fire cover (5) of the combustor (1) for the gas stove comprises a cover bodypart (51) and a surrounding wall body part (52); the wall body part (52) defines a recess part (50) for accommodating gas; the fire cover (5) is provided with multiple fire outlet holes (501) communicating with the recess part (50); and an air channel (500) is formed in the wall body part (52). Areas near the fire outlet holes can be supplemented for sufficient secondary air without disturbing combusting flame; and full and stable combustion of gas of the combustor can be guaranteed.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

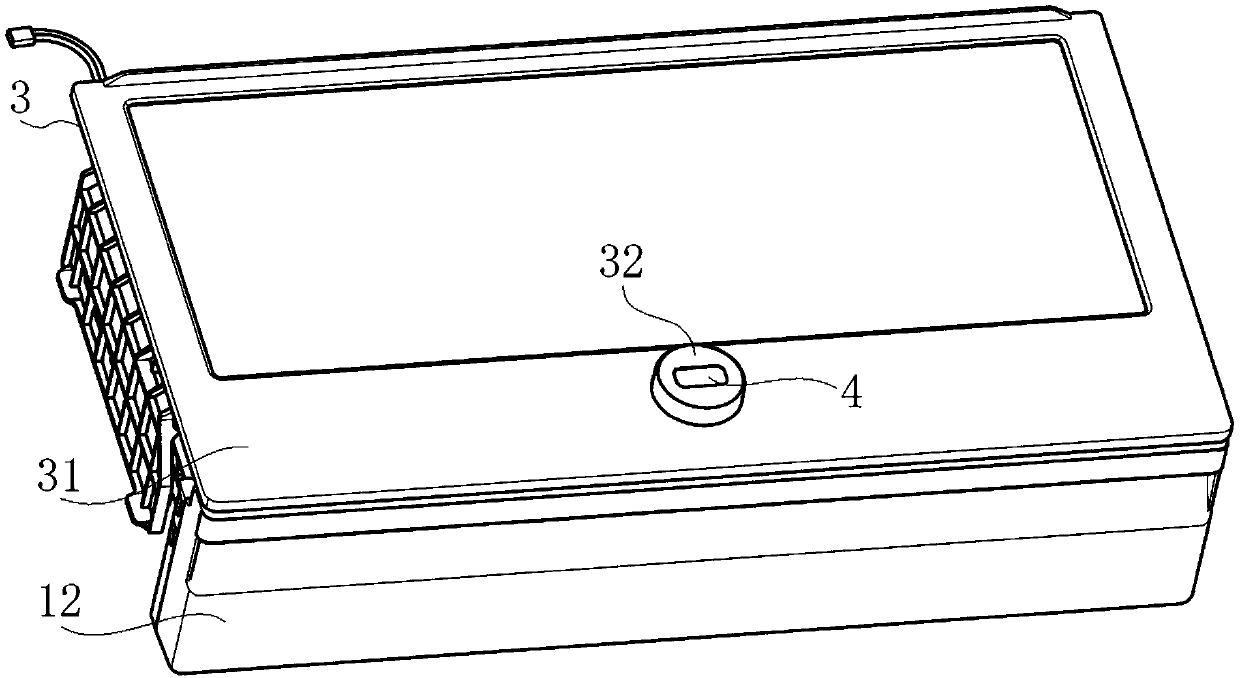

Humidity regulating drawer and refrigerator for refrigerator

ActiveCN106288629BSimple structureReduce manufacturing costLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigeration

The embodiment of the invention provides a humidity adjustment drawer for a refrigerator and the refrigerator, relates to the technical field of refrigeration equipment, and aims to solve the problem that an existing drawer type humidity adjustment device is complicated in structure and high in cost. The humidity adjustment drawer for the refrigerator comprises a drawer body, wherein an opening of the drawer body is movably connected with a drawer cover plate; a shelf of the refrigerator is arranged above the drawer cover plate; the upper surface of the shelf is rotationally connected with a knob; the position, which is deviated from the rotating center of a knob, below the knob is connected with an eccentric rod; a yielding hole is formed in the shelf; a long hole is formed in the drawer cover plate; an eccentric rod is arranged in a manner of passing through the yielding hole and the long hole in sequence; when the knob is rotated, the eccentric rod can push the side wall of the long hole, so that the drawer cover plate moves relative to the drawer body to adjust the size of a gap between the drawer cover plate and the drawer body. The humidity adjustment drawer, provided by the embodiment of the invention, for the refrigerator is used for storing fruits and vegetables under a proper humidity condition.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

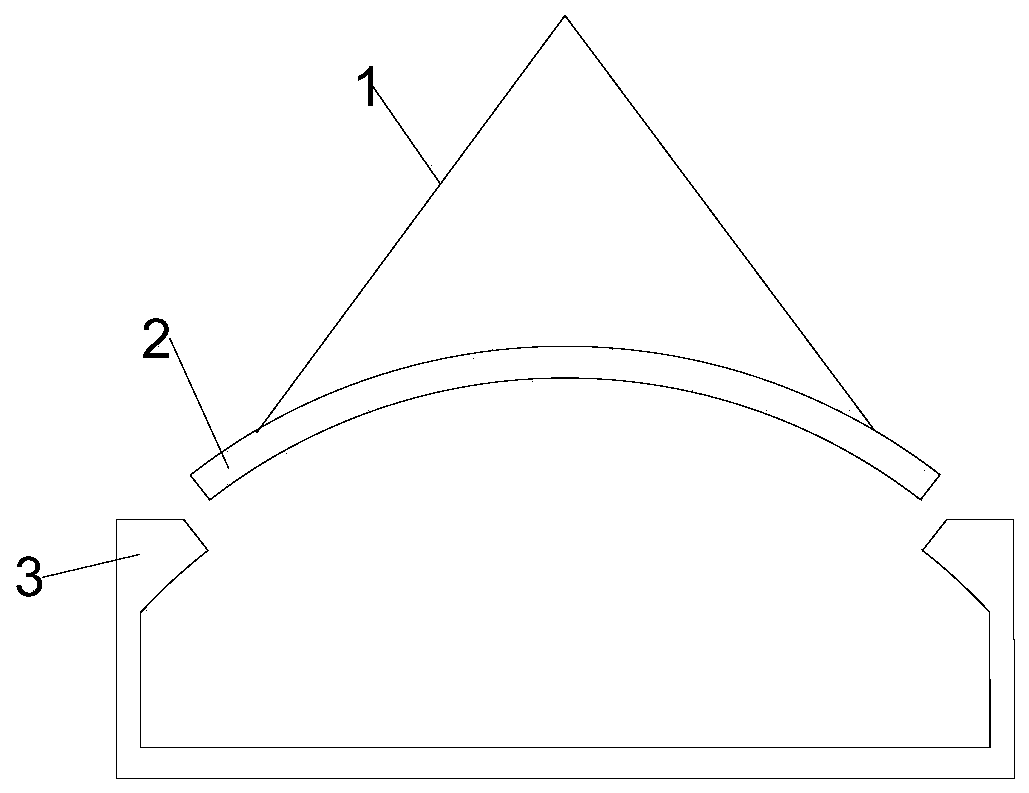

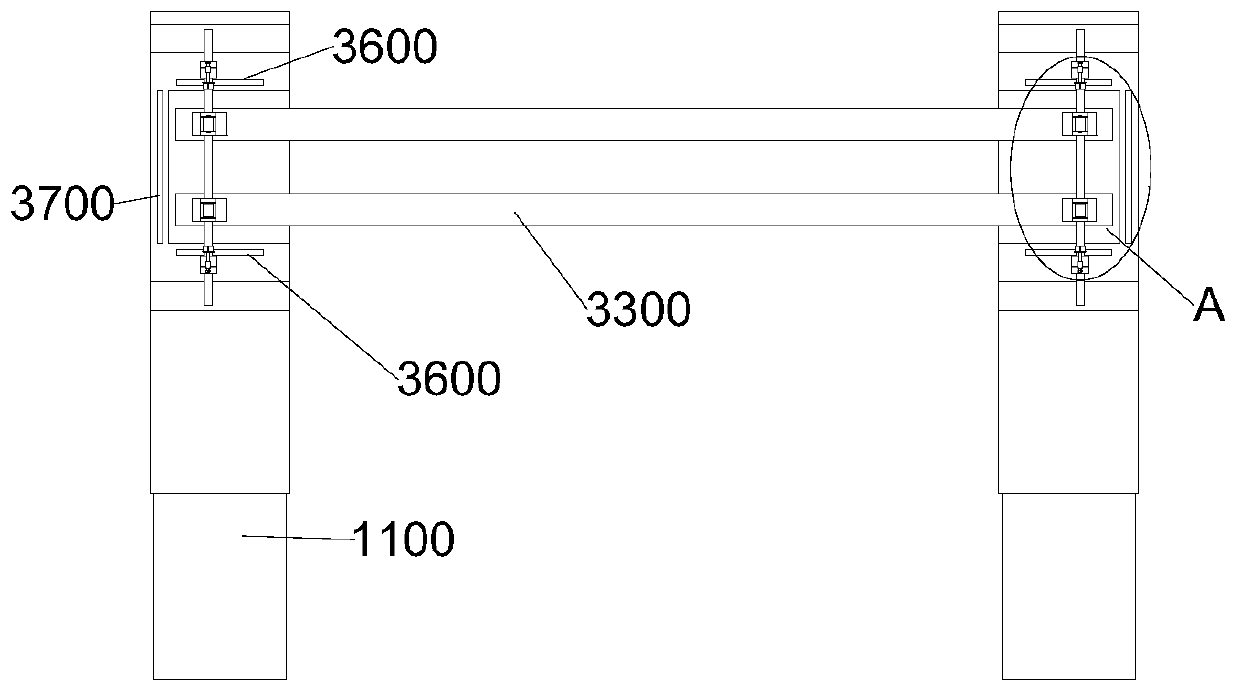

Transportation and erecting all-in-one machine and transportationand erecting construction method of precast component

PendingCN110029587APrecise positioningHigh positioning accuracyBridge erection/assemblyMechanical engineeringPositioning system

The invention relates to a transportationand erecting all-in-one machine and a transportation and erecting construction method of a precast component. The transportation and erecting all-in-one machine is used for transportation and erection of a precast component on a pier base, and includes a walking mechanism, a first height adjusting mechanism, a horizontal adjusting mechanism and a second height adjusting mechanism. The first height adjusting mechanism is arranged on the walking mechanism. The horizontal adjusting mechanism is arranged on the first height adjusting mechanism. Thesecond height adjusting mechanism is movably arranged on the first height adjusting mechanism and used for bearing the precast component. The walking mechanism is used for roughly adjusting the horizontal direction of the precast component, the first height adjusting mechanism is used for roughly adjusting the height of the precast component and completing falling-erecting work, the horizontal adjusting mechanism is used for accurately adjusting the horizontal direction of the precast component, and the second height adjusting mechanism is used for accurately adjusting the height of the precast component. The transportation and erecting all-in-one machine and the transportation and erecting construction method of the precast componenthave the advantage that a two-stage positioning system is adoptedto facilitateaccurate positioning of the precast component.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Structure for preventing soft plastic appearance from being pulled to be sunken

InactiveCN103934954AAppearance does not affectSimple structureDigital data processing detailsMechanical engineeringBody surface

A structure for preventing soft plastic appearance from being pulled to be sunken is applied to a forming overmold product, and the inner side of the product is a non-appearance surface. The structure for preventing the soft plastic appearance from being pulled to be sunken comprises hard plastic and soft plastic, wherein the hard plastic comprises a hard plastic body and a plurality of flash grooves formed from the hard plastic body surface to the hard plastic body, the flash grooves are positioned in the non-appearance surface at the inner side of the product, the soft plastic comprises a soft plastic body and an extension part protruding from the soft plastic body surface, the soft plastic body surface is in contact with the hard plastic body surface, the extension part is inserted into the flash grooves in a matched way, the flash grooves are positioned on the non-appearance surface at the inner side of the product, and a soft plastic inlet point is positioned at the lower end of the extension part. The structure for preventing the soft plastic appearance from being pulled to be sunken, disclosed by the invention, is applicable for a non-appearance part at the inner side of the product, is simple and is convenient to process, and product appearance can be better prevented from being pulled to be sunken.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

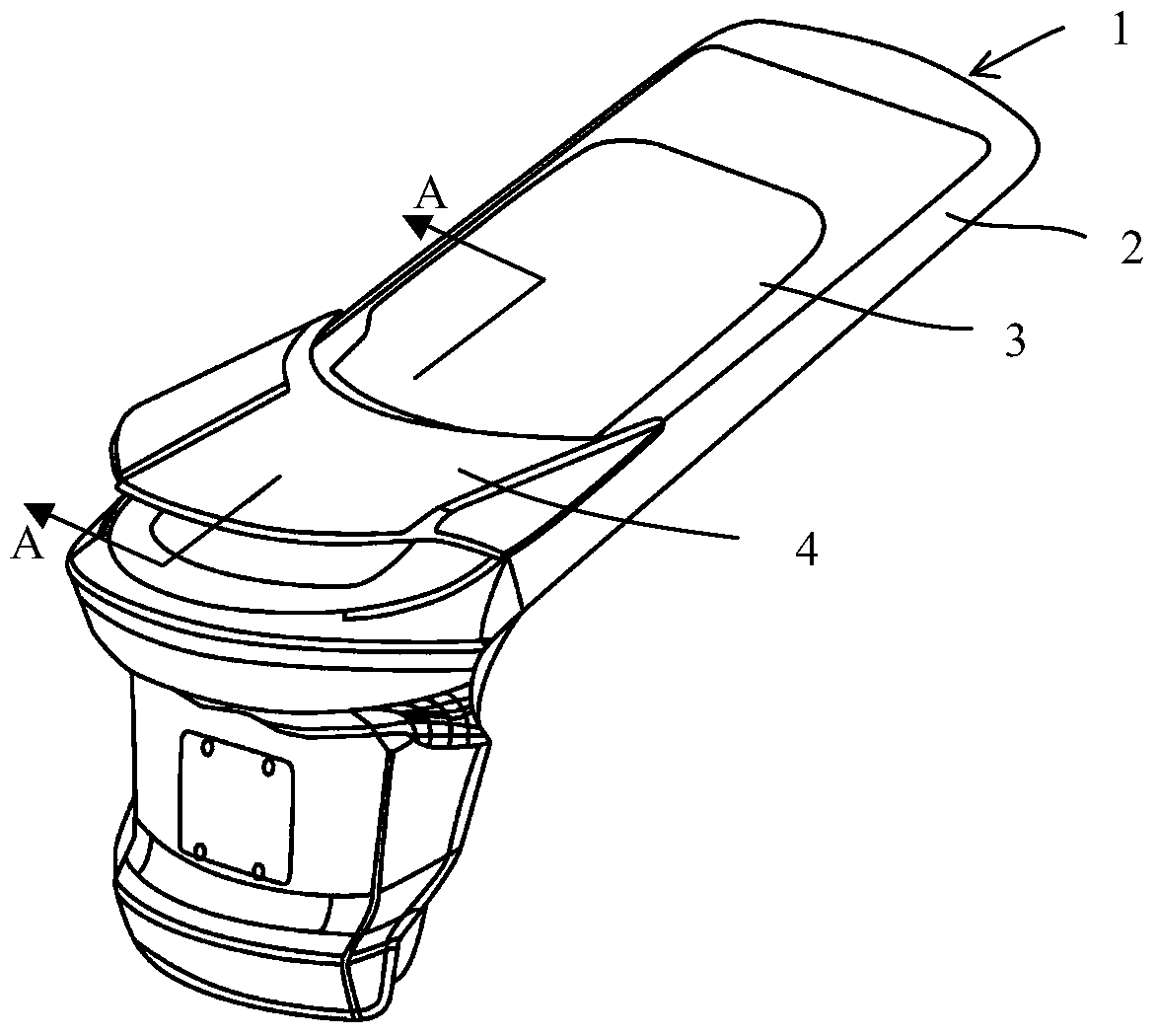

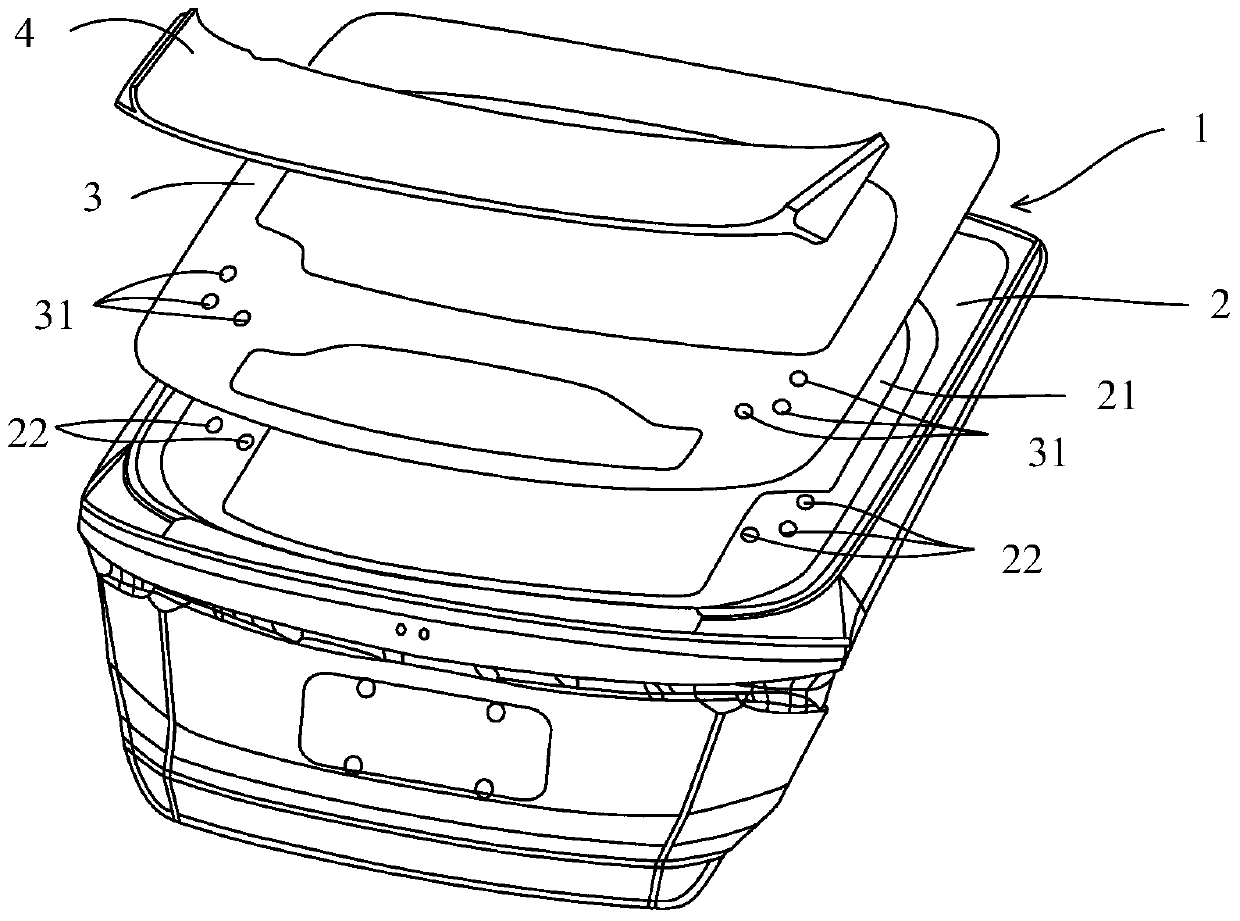

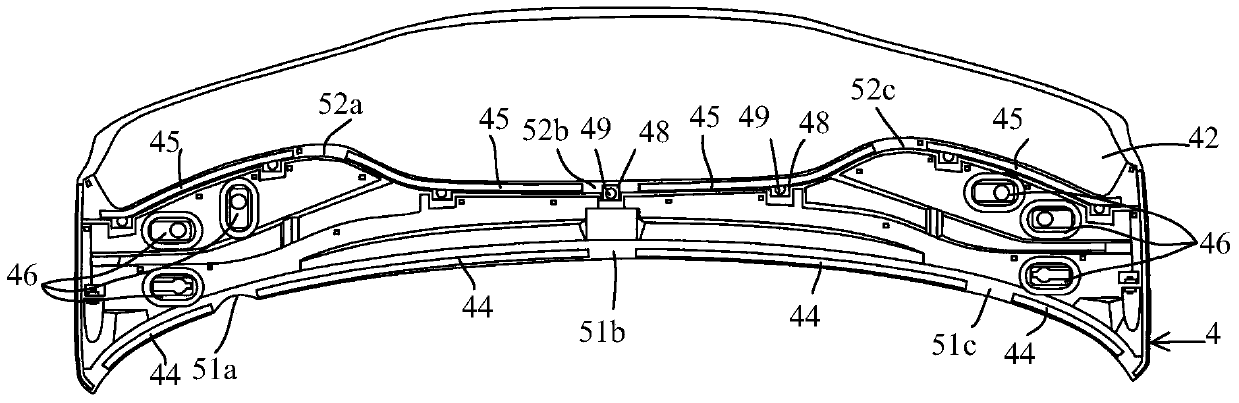

Vehicle rear structure

ActiveCN107599999BGood lookingAppearance does not affectVehicle body streamliningDoorsAdhesiveEngineering

The invention provides a vehicle rear part construction comprising a tail door assembly (2), tail door glass (3), a spoiler (4), a long side of which extends in a vehicle width direction, having sealed contact with the tail glass on the whole and mounted to the tail assembly via the tail door glass, a front edge adhesive tape (44) arranged between a front edge of the spoiler and the tail door glass, and a back edge adhesive tape (45) arranged between a back edge of the spoiler and the tail door glass, wherein drain holes (51a,51b,51c,52a,52b,52c) are evenly formed in the front and back edge adhesive tapes. According to the invention, the vehicle rear part construction is provided in a way that even upon limitation of space between the spoiler and an automobile sheet metal plate, rainwaterand garbage can be timely removed when contour of the vehicle rear part, and sealed contact between the spoiler and the tail door glass can be reliably guaranteed; and the vehicle rear part construction is simply structured and requires low cost.

Owner:HONDA MOTOR CHINA INVESTMENT CO LTD

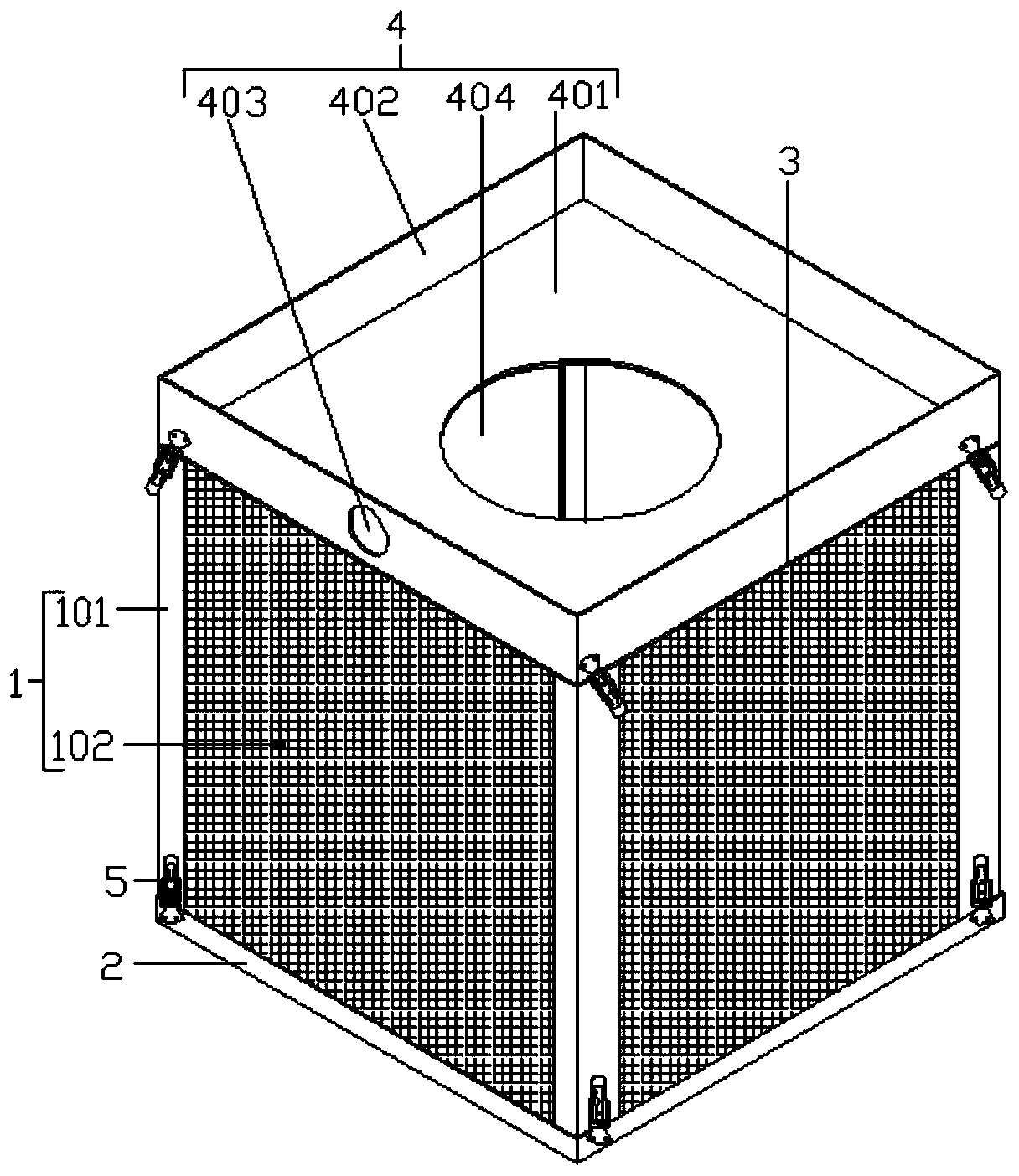

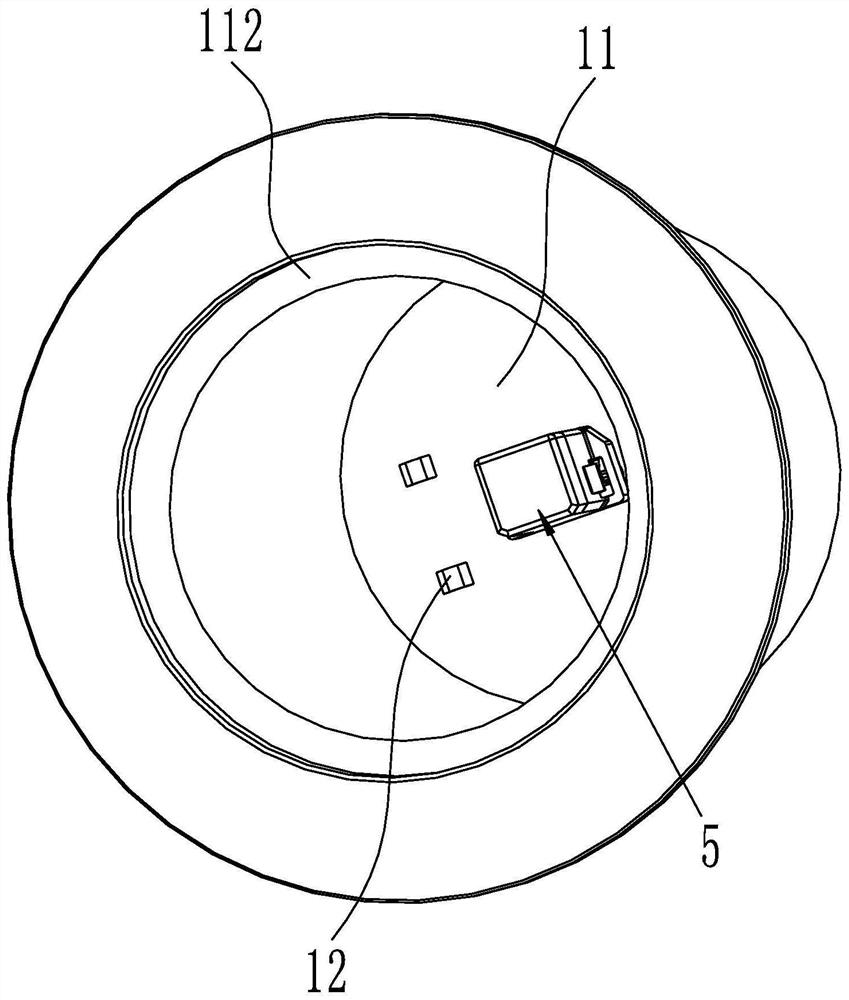

Double-layer filter element in garbage can of sweeping vehicle

PendingCN109944195AReduce usageFlexible collocationDispersed particle filtrationRoad cleaningAir filterEngineering

The invention provides a double-layer filter element in a garbage can of a sweeping vehicle. The double-layer filter element comprises a steel wire filter cylinder, wherein the bottom of the steel wire filter cylinder is connected with a lower bottom plate, and the top of the steel wire filter cylinder is connected with an upper cover plate. The double-layer filter element is characterized in thatan air filter element body is arranged in the steel wire filter cylinder; the upper end of the air filter element body is connected with the upper cover plate; the lower end of the air filter elementbody is connected with the lower bottom plate, and the upper end face of the upper cover plate is connected with a sealing structural member. According to the double-layer filter element, through aninstallation method of the double-layer filter element in the garbage can of the sweeping vehicle, matching is more flexible, dust fall can be achieved by independently using a platy steel wire filterscreen during wet operation, the use frequency of the air filter element body is reduced, another air filter element body can be additionally mounted for dry operation, and the filtering effect is better and stronger. The double-layer filter element has no influence on appearance modeling, realizes the purposes of easy assembly and disassembly, high reliability and good effect, and can be widelyapplied to the interiors of garbage cans of electric sweeping vehicles.

Owner:海汇新能源汽车有限公司

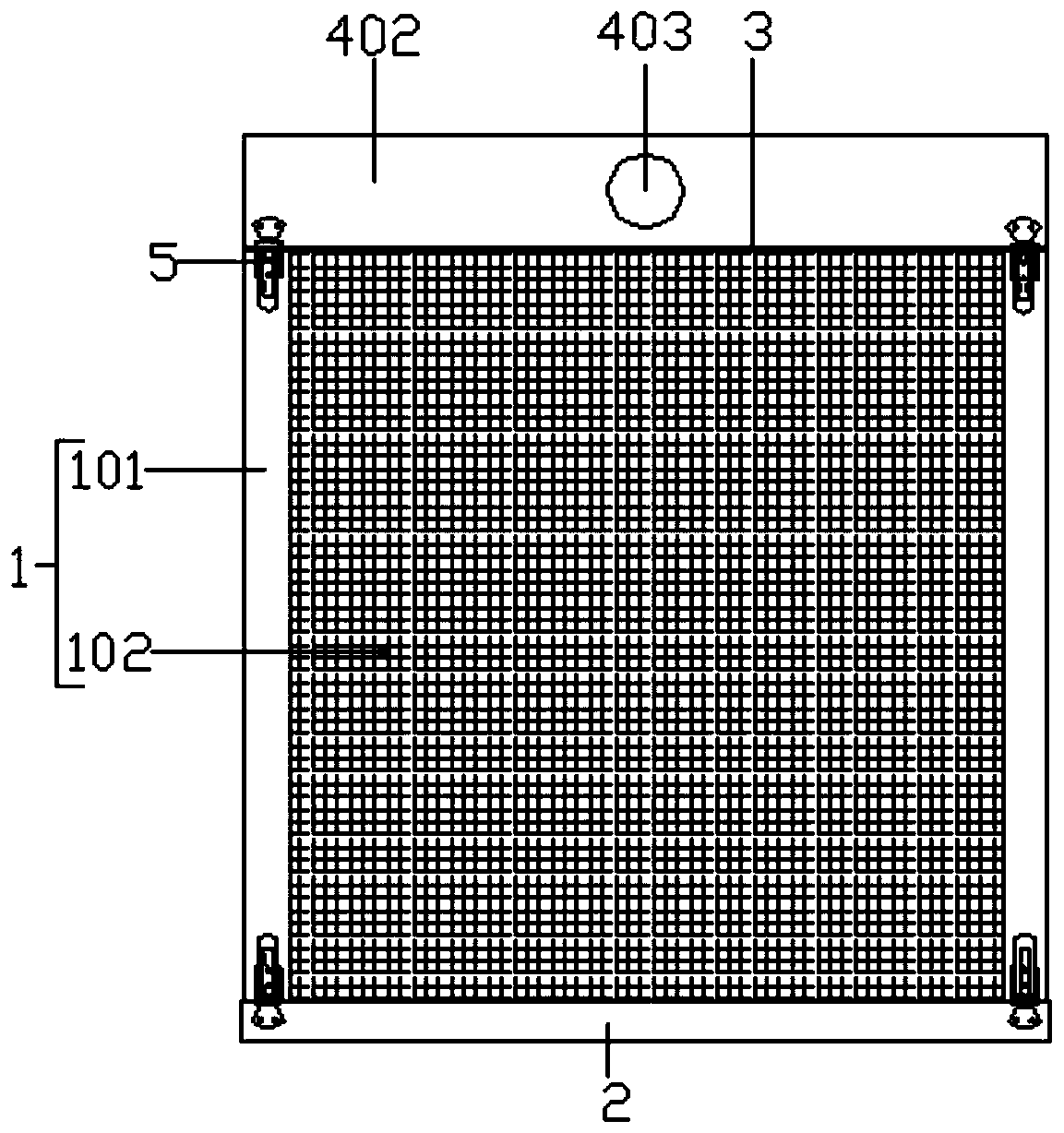

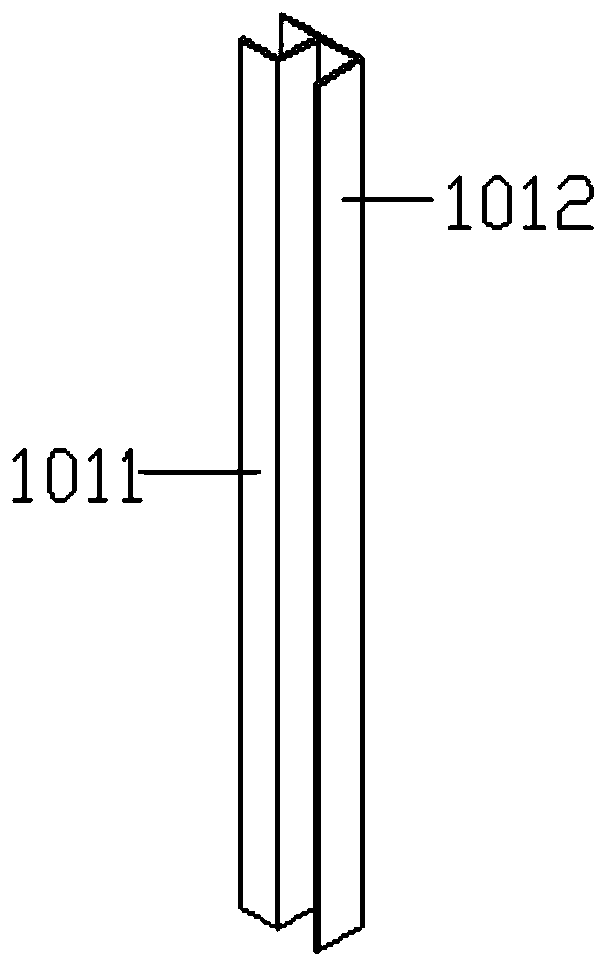

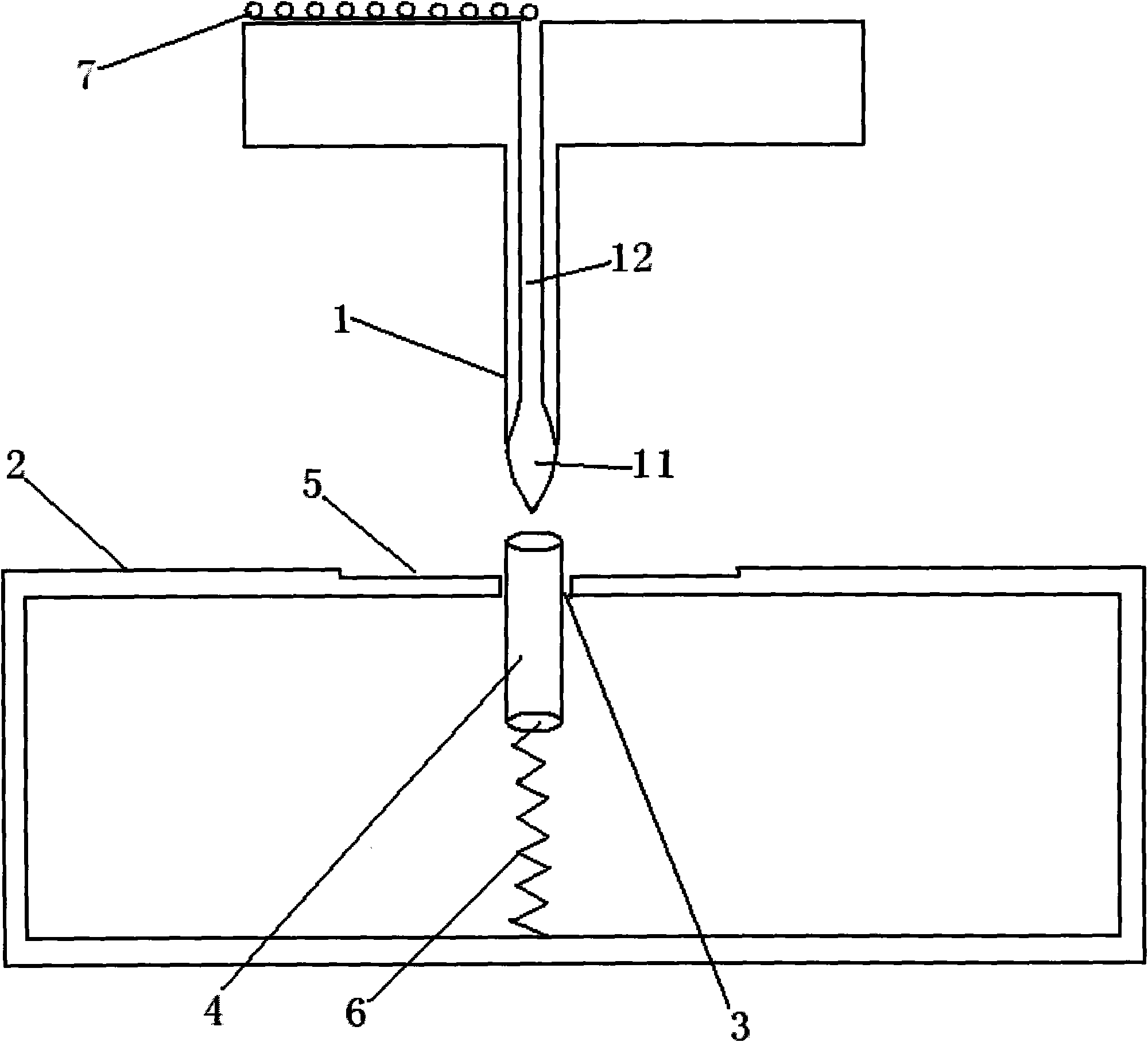

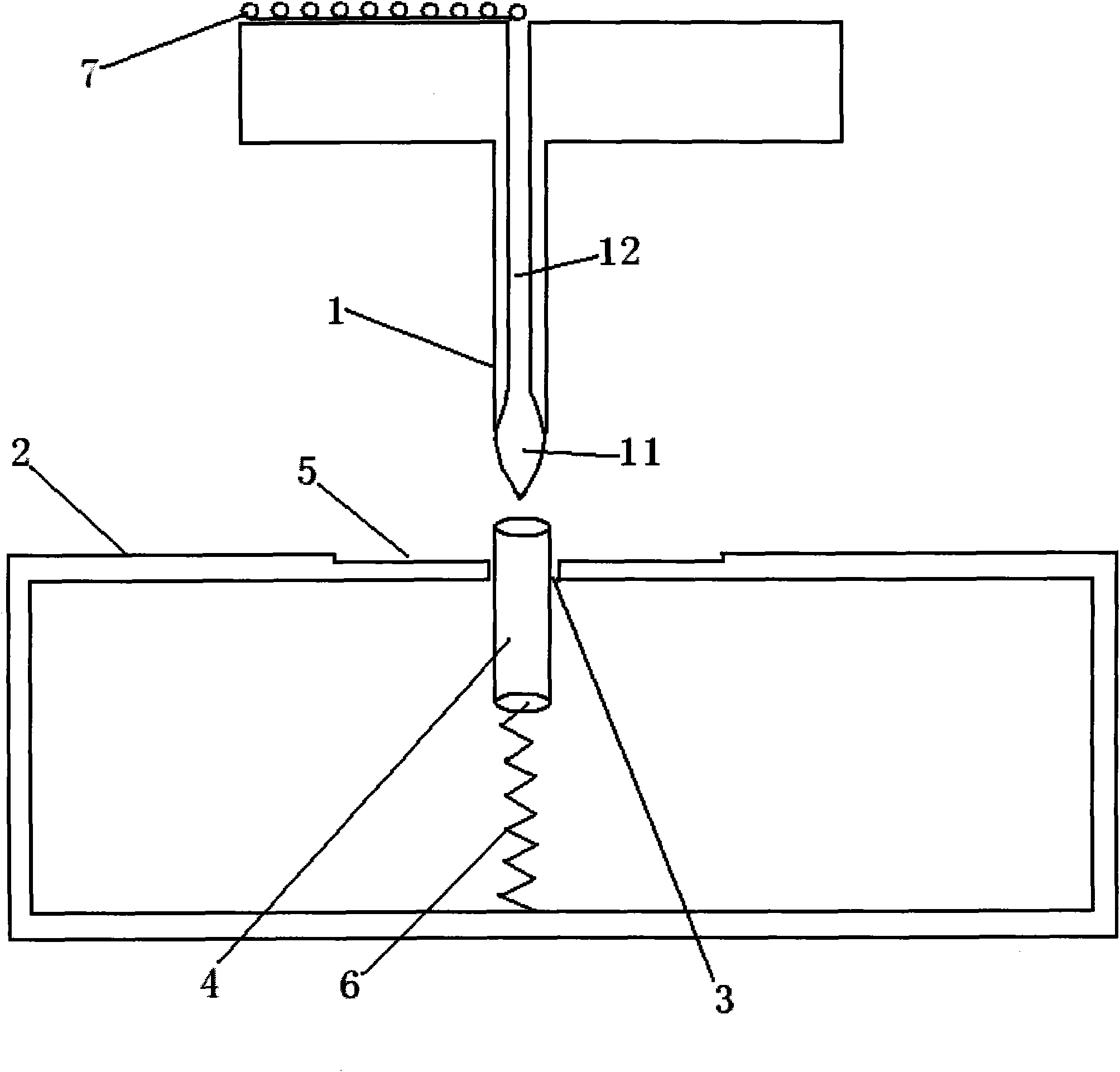

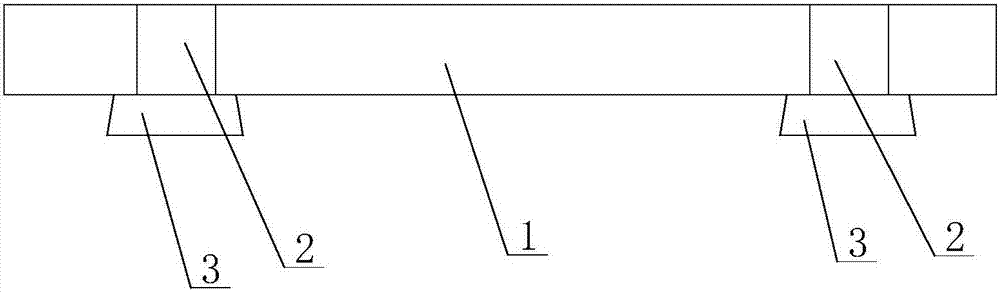

Hand tag pining machine

InactiveCN102396823AGood lookingAppearance does not affectClothes making applicancesBiomedical engineeringMetal

The invention discloses a hand tag pinning machine, which comprises a tag pin (1) and a support (2) arranged below the tag pin (1), wherein the upper part of the support (2) is provided with a pin hole (3) through which the tag pin (1) passes; a metal round tube (4) is arranged in the pin hole (3) below the tag pin (1); the head part of the metal round tube (4) extends out of the pin hole (3); the bottom of the metal round tube (4) is arranged on the support (2) through a spring (6); and the caliber of the metal round tube (4) is bigger than the pin head (11) of the tag pin (1), and is smaller than the pin groove (12) part of the tag pin (1). The hand tag pinning machine is simple in structure and convenient for use and can correctly determine the pinning position of a plastic pin on a tag and improve the appearance of a product.

Owner:江苏兴达利集团有限公司

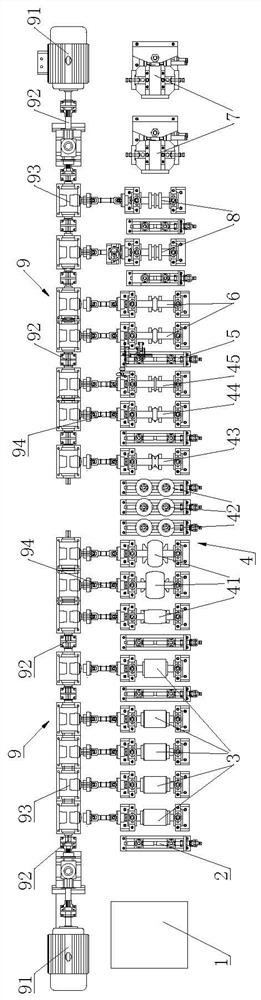

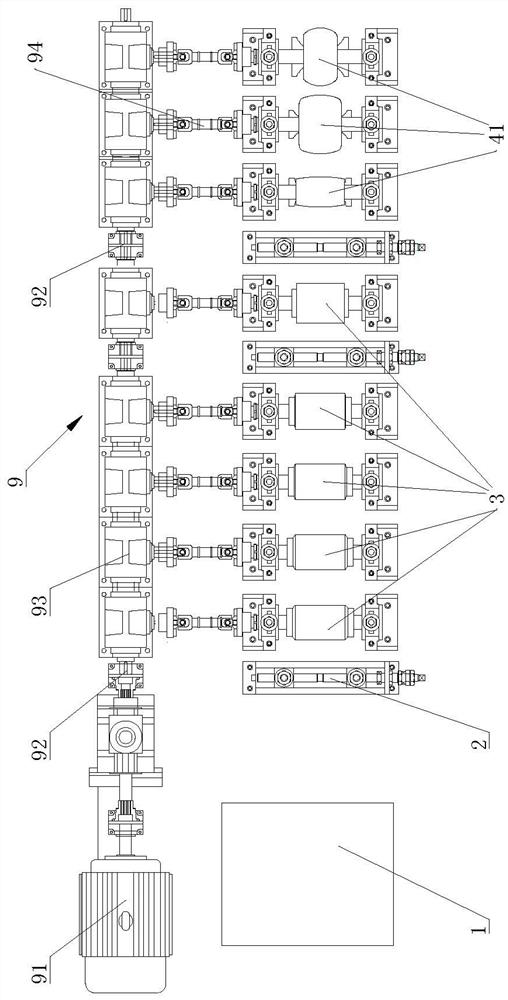

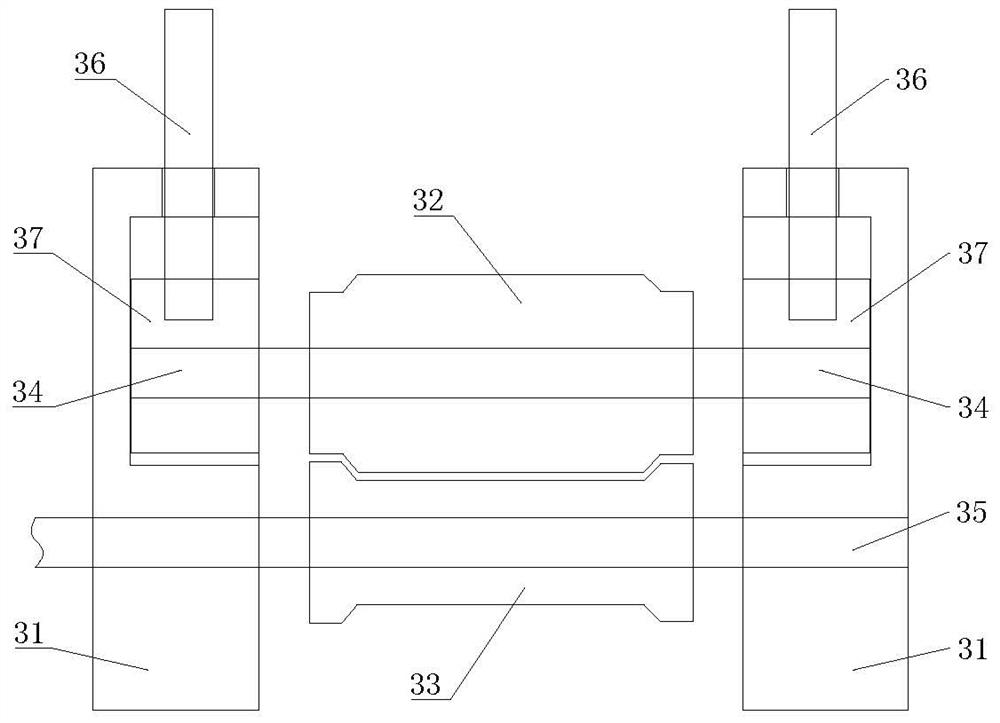

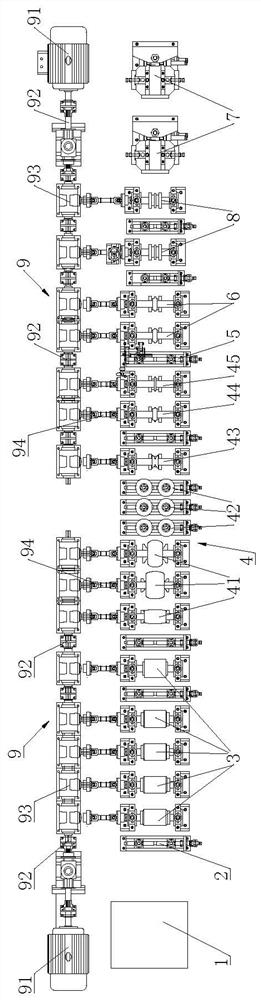

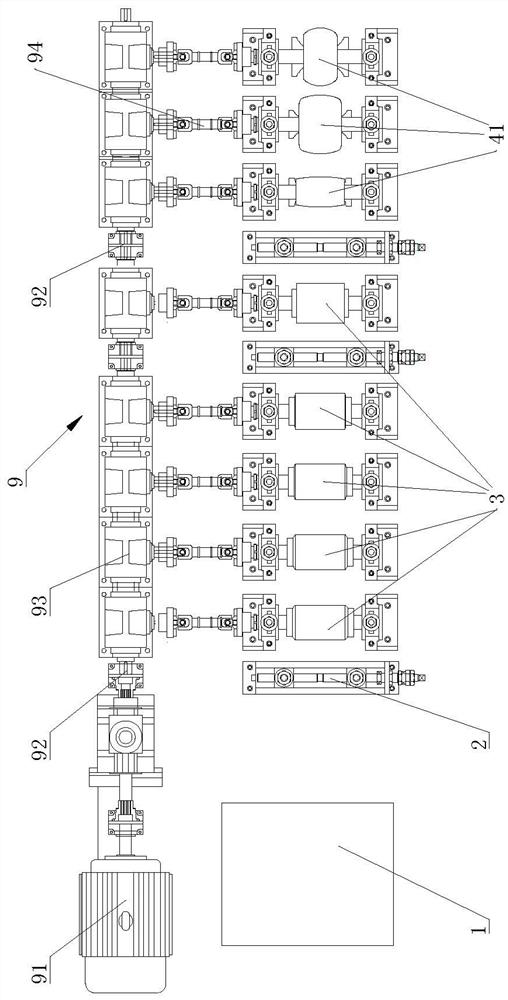

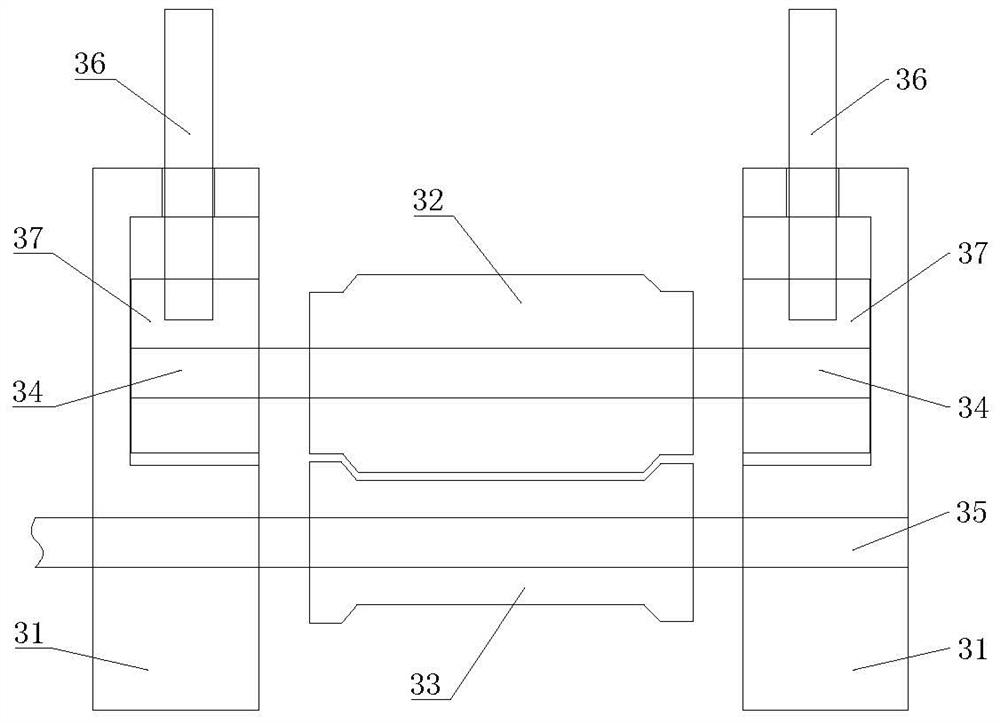

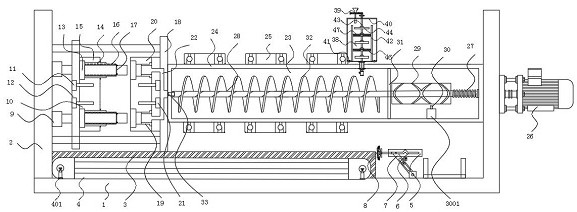

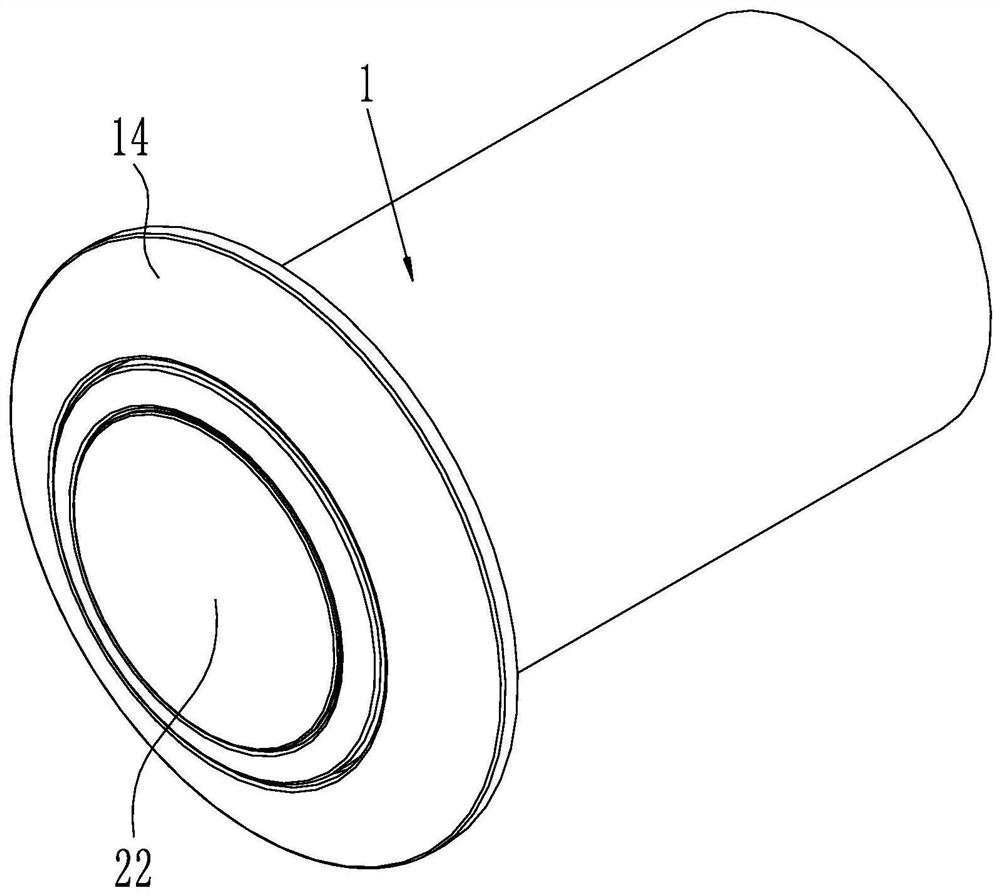

Efficient polishing-free automatic pipe making machine and pipe making method

ActiveCN112355663ADoes not affect appearanceAppearance does not affectOther manufacturing equipments/toolsPolishingSteel belt

The invention discloses an efficient polishing-free automatic pipe making machine and a pipe making method. The pipe making machine comprises a steel belt unwinding device, a steel belt flattening device, a steel belt edge folding device, a steel belt folding device, a folding and welding device, a steel pipe shaping device and a shaping sizing device which are arranged in sequence. The steel beltedge folding device presses the edges of two sides of a flattened steel belt into right-angled secondary bent edges, the steel belt folding device presses the steel belt to enable two side edges of the steel belt to be gradually bent upward and then folded, and the edges of two sides of the steel belt of the folding and welding device are welded to form a steel pipe. According to a pipe manufacturing process, the two edges of the steel belt are gradually pressed into the groove shape, then the steel belt is folded, the edges on two sides are located in the groove body after being folded, andduring use, a weld joint can be shielded in the groove, so that the using appearance is not affected. Therefore, it is not needed to polish the weld joint, and the production efficiency can be greatlyimproved and the problems caused by weld joint grinding are solved. The surface of a tubular product is free of weld joints and polishing traces, the surface state can be smooth easily, and the product quality is improved.

Owner:佛山市卓粤建澜机械科技有限公司

High-efficiency grinding-free automatic pipe making machine and pipe making method

ActiveCN112355663BDoes not affect appearanceAppearance does not affectOther manufacturing equipments/toolsWeld seamSteel belt

The invention discloses a high-efficiency grinding-free automatic pipe making machine and a pipe making method. The pipe making machine includes a steel strip unwinding device, a steel strip flattening device, a steel strip hemming device, a steel strip closing device, and a closing welding device arranged in sequence. 1. Steel pipe shaping device and shaping and sizing device. The steel strip folding device presses the two side edges of the flattened steel strip into right-angled secondary bending edges. The steel strip closing device presses the steel strip to make the steel strip The two sides are gradually bent upwards and then closed, and the two sides of the steel belt of the closing welding device are welded to form a steel pipe. The pipe-making process adopted in the present invention gradually presses the two edges of the steel strip into a groove shape, and then closes the steel strip. After closing, the edges on both sides are located inside the groove body. When in use, the weld seam will be covered in the groove without affecting Use appearance. Therefore, the welding seam does not need to be polished, which can greatly improve the production efficiency and the problems caused by the welding seam grinding. There are no weld seams or grinding marks on the surface of the pipe, and the surface state can be easily smoothed to improve product quality.

Owner:佛山市卓粤建澜机械科技有限公司

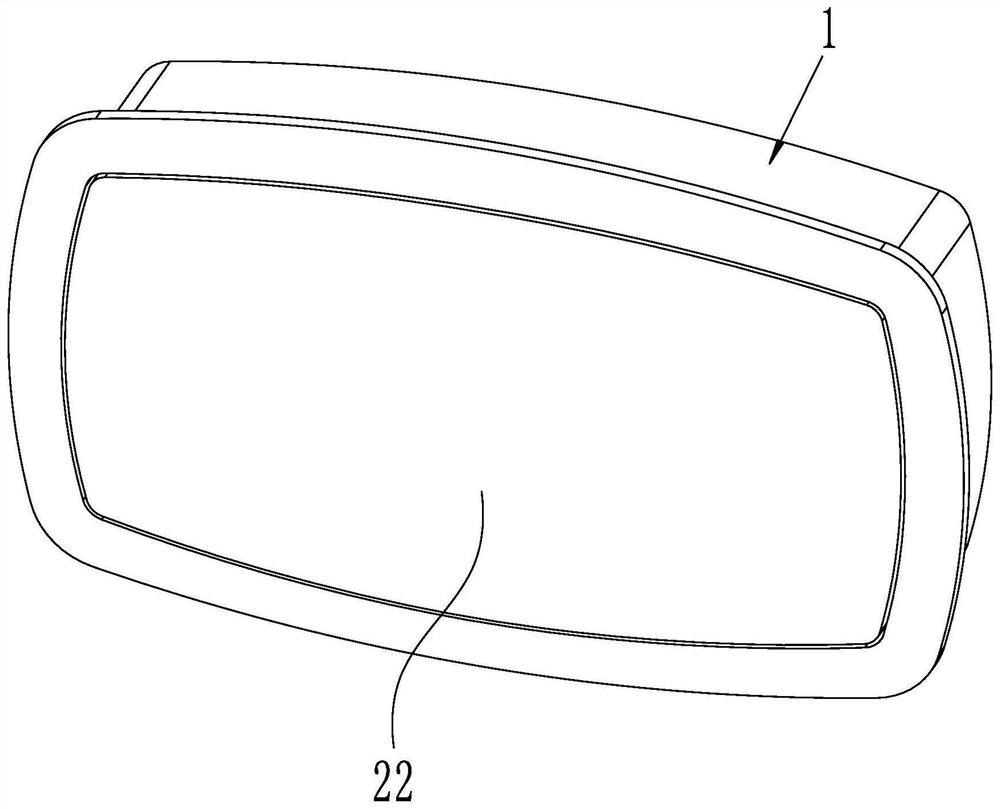

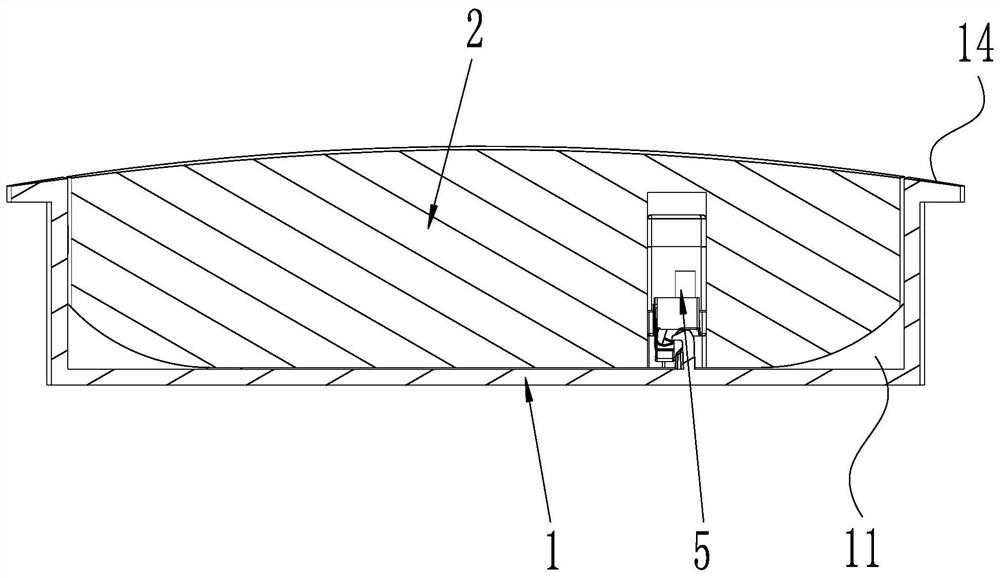

Integrated vehicle lamp with fixed lighting and movable lighting functions

ActiveCN111928153AImprove lighting effectsIncrease flexibilityElectric circuit arrangementsWith built-in powerEngineeringFlashlight

The invention discloses an integrated vehicle lamp with fixed lighting and movable lighting functions. The integrated vehicle lamp comprises a lamp mounting base and an integrated lamp body. The lampmounting base is of a box-shaped structure and can be installed on a metal plate of an automobile. The integrated lamp body is detachably installed on the lamp mounting base and comprises a lamp shell, a fixed illumination light-emitting face and a movable illumination light-emitting face, the fixed illumination light-emitting face and the movable illumination light-emitting face are both arrangedon the lamp shell, and the fixed illumination light-emitting face and the movable illumination light-emitting face are independently controlled. By the adoption of the technical scheme, waste is turned into wealth, when the integrated lamp body is mounted on the lamp mounting base, the fixed illumination light-emitting surface can provide conventional illumination, when the integrated lamp body is detached from the lamp mounting base, the movable lighting light-emitting surface can provide movable lighting, so that the integrated lamp body can be used as a flashlight to light any place needing to be lighted, and the integrated vehicle lamp is good in lighting effect, extremely high in flexibility, attractive, elegant, compact in structure, convenient to store and use and extremely high inpracticability.

Owner:CHONGQING REBO LIGHTING & ELECTRONICS

An enamel liner for cooking utensils

ActiveCN108158387BGuaranteed non-stickImprove corrosion resistanceCooking-vessel materialsCooking vessel constructionsCast ironCoating

The invention provides an enamel inner pot for cooking utensils, comprising a cast iron pot body, an enamel glaze layer is sintered on the outer surface of the cast iron pot body, and a non-stick coating is sprayed on the inner surface of the cast iron pot body. There is a radially outward flange at the gall opening of the flange, the enamel glaze layer and the non-stick coating both extend to the flange, and the outer end surfaces of the flange are respectively provided with the top surface and the bottom surface of the flange. A corner, where the junction of the enamel layer and the non-stick coating is located. The inner liner disclosed by the invention has a non-stick coating layer and an enamel glaze layer on the inner and outer surfaces respectively, and has the characteristics of less defects, beautiful appearance and good hand feeling.

Owner:JOYOUNG CO LTD

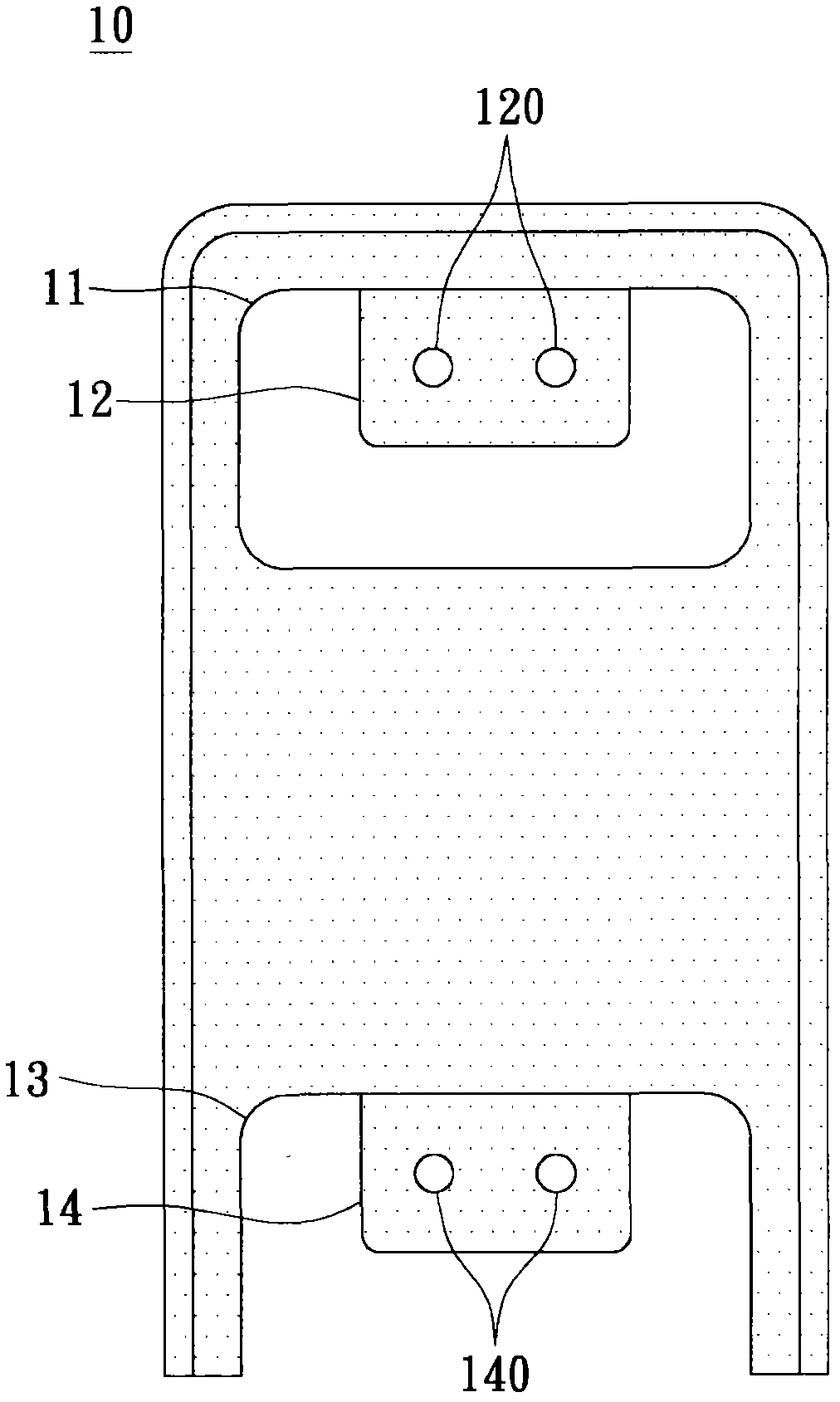

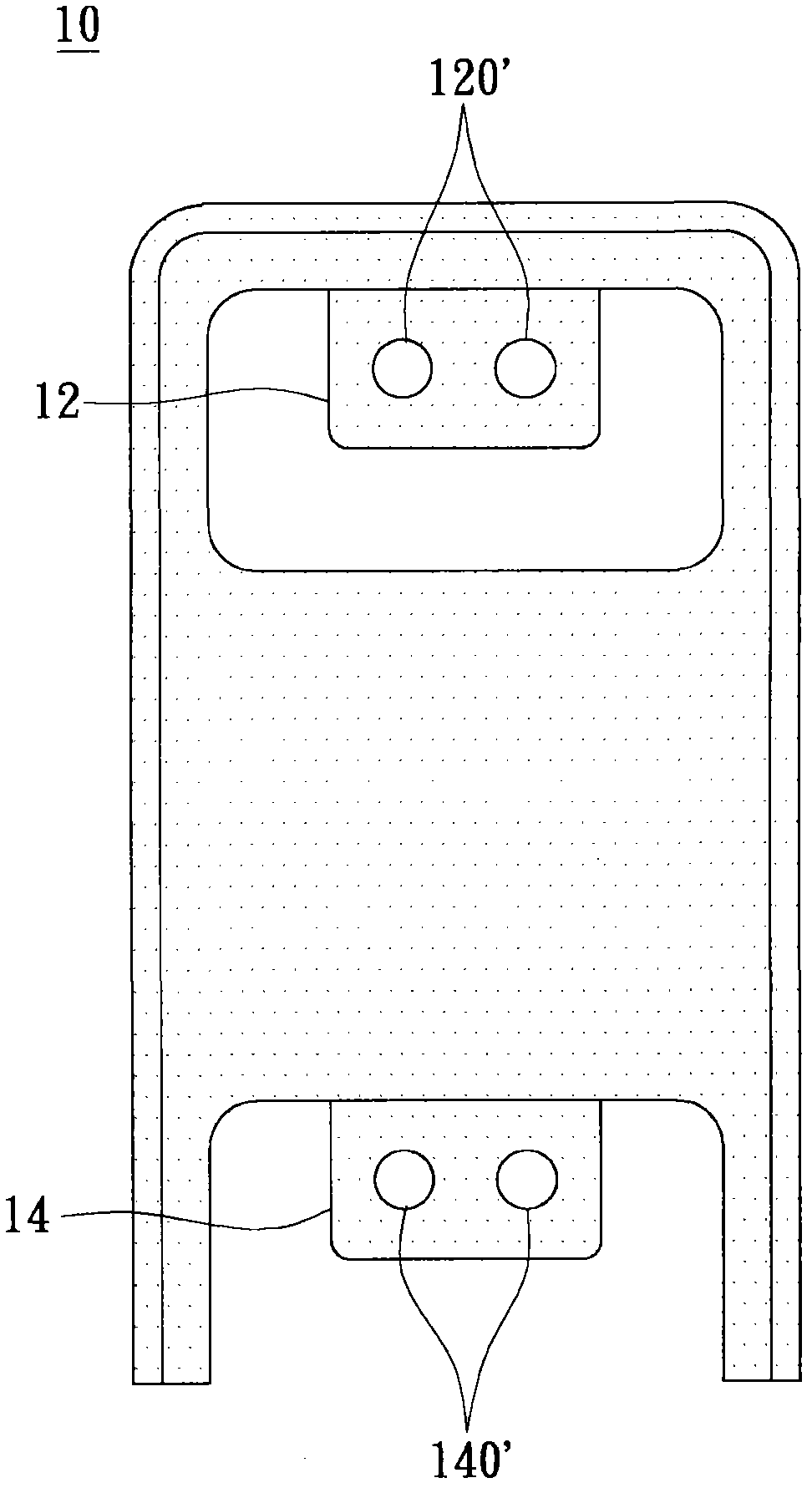

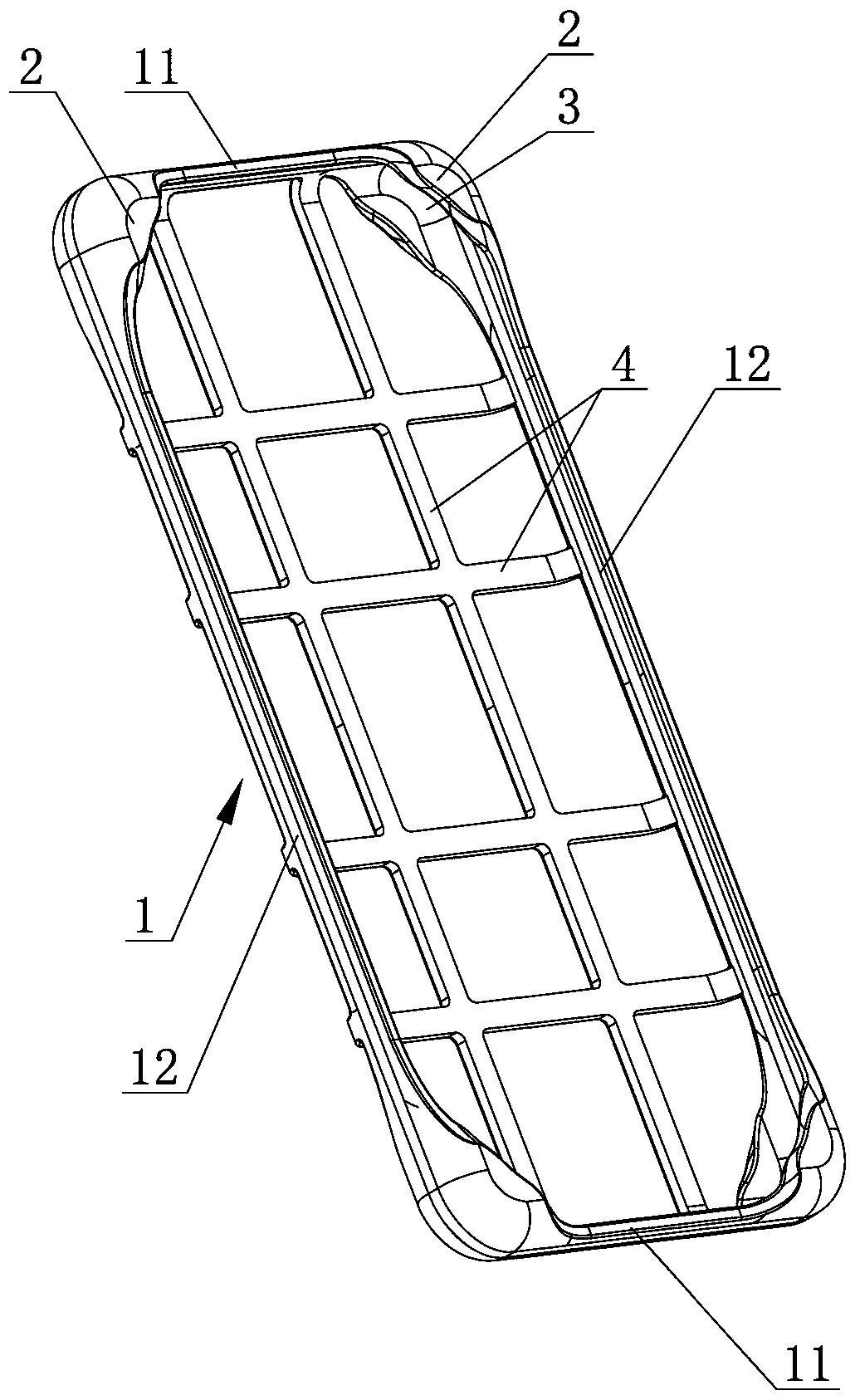

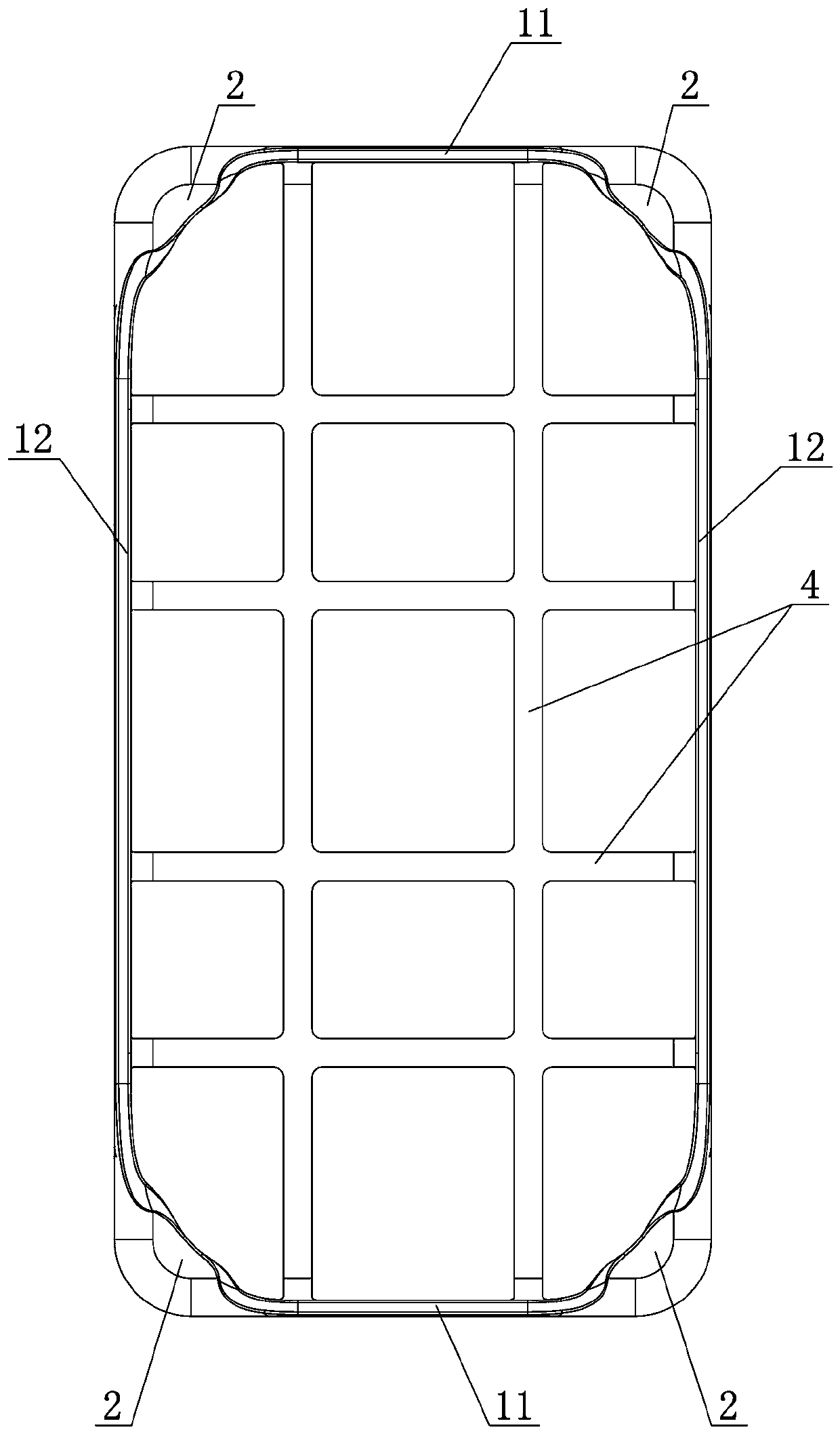

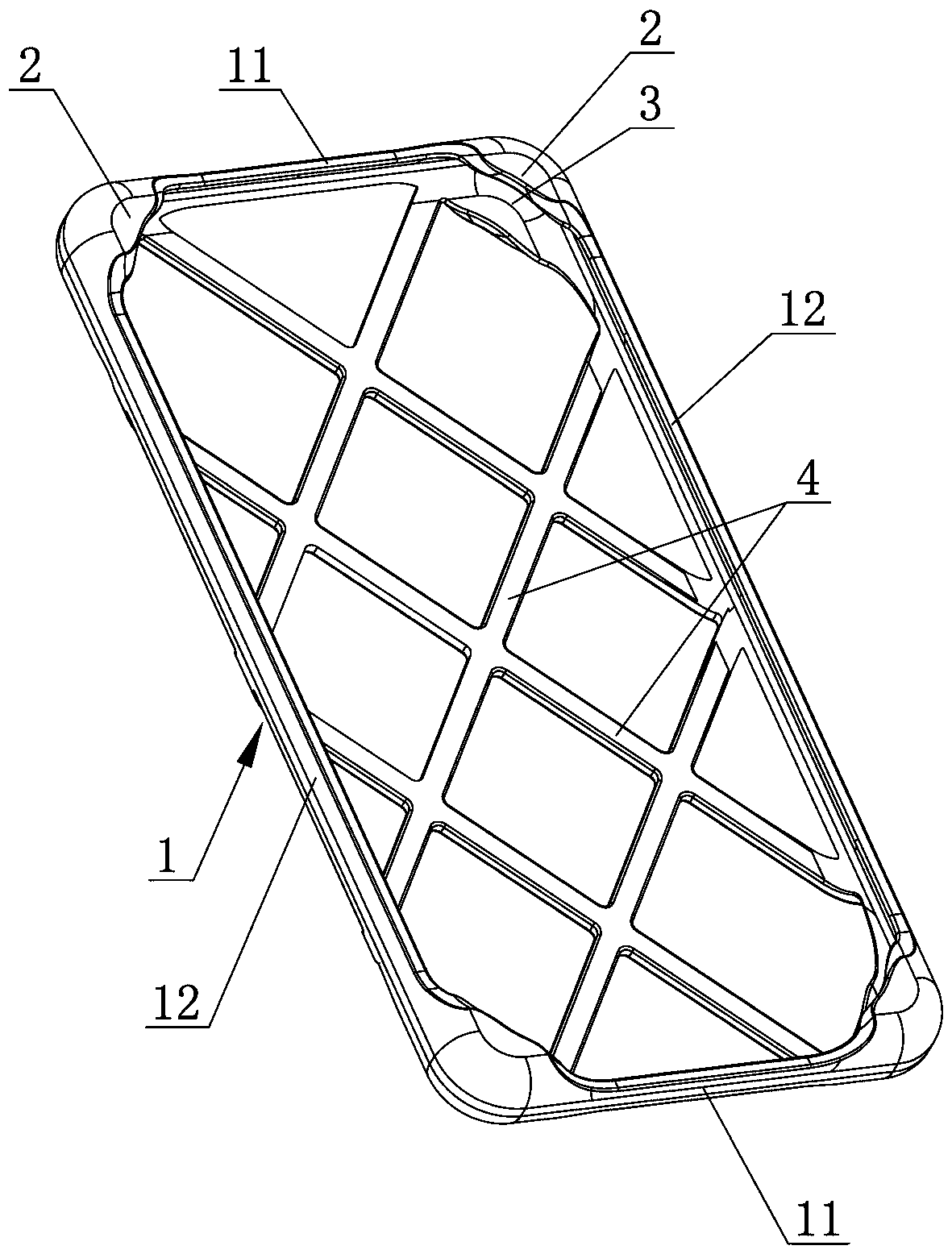

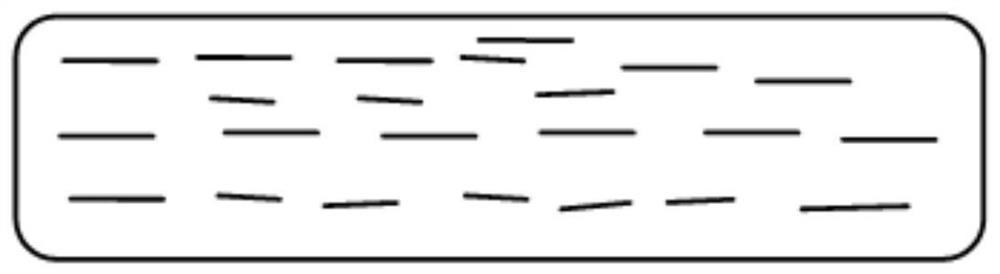

Universal flexible glue mobile phone shell

PendingCN111343320AAppearance does not affectImprove cooling effectTelephone set constructionsMechanical engineeringMobile phone

The invention relates to the technical field of portable electronic equipment peripheral products, in particular to a universal flexible glue mobile phone shell. The universal flexible glue mobile phone shell comprises a shell body and wrap angle structures located at four corners of the shell body. The front side of each wrap angle structure is provided with a baffle plate used for hanging corners of a mobile phone and a concave wrap angle integrally formed with the baffle plate. The shell comprises two transverse surrounding edges and two vertical surrounding edges, the two transverse surrounding edges and the two vertical surrounding edges are connected end to end to form a rectangular surrounding edge, the rectangular surrounding edge is connected with a plurality of elastic ribs whichare arranged in a staggered mode, and the wrap angle structures, the rectangular surrounding edge and the elastic ribs are integrally formed by soft elastic materials in an injection molding mode. The flexible glue mobile phone shell can be suitable for mobile phones with different sizes from 4 inches to 7 inches, is also suitable for folding mobile phones, and is high in universality. Compared with a mobile phone shell completely wrapped in the market, the mobile phone shell can effectively accelerate heat dissipation, heat is prevented from being gathered in the mobile phone shell, and thepracticability is higher.

Owner:马泽楠

Fire cover for burner of gas stove, gas stove and burner of gas stove

The invention discloses a fire cover of a combustor for a gas stove, the gas stove and the combustor of the gas stove. The fire cover (5) of the combustor (1) for the gas stove comprises a cover bodypart (51) and a surrounding wall body part (52); the wall body part (52) defines a recess part (50) for accommodating gas; the fire cover (5) is provided with multiple fire outlet holes (501) communicating with the recess part (50); and an air channel (500) is formed in the wall body part (52). Areas near the fire outlet holes can be supplemented for sufficient secondary air without disturbing combusting flame; and full and stable combustion of gas of the combustor can be guaranteed.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

A kind of unmanned aerial vehicle automatic charging control device and charging method

ActiveCN106058985BAppearance does not affectImprove labor efficiencyCircuit monitoring/indicationSafety/protection battery circuitsAutomatic controlElectrical polarity

Owner:青岛海盾雷达声纳工程技术有限公司

A locking mechanism for a drum washing machine dispenser

ActiveCN104775279BGood lookingAppearance does not affectOther washing machinesTextiles and paperLocking mechanismDistributor

The invention discloses a locking mechanism for a roller washing machine distributor, and belongs to the field of washing machines. The locking mechanism comprises a distributor handle and a main control board, wherein the main control board is provided with an assembling hole for mounting the distributor handle; the distributor handle is in splicing fit with the main control board through the assembling hole; a clamping hook is arranged inside the main control board; the distributor handle is provided with an inverted buckle; the clamping hook is clamped with the inverted buckle; the clamping hook comprises an elastic cantilever and a clamping table; the clamping table is fixed at the free end of the cantilever; the fixed end of the elastic cantilever is fixed on the inner edge of the side wall of the assembling hole. The locking mechanism provided by the invention can be clamped stably, the distributor handle is simple and attractive in appearance, and the visual feel of a user is good.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

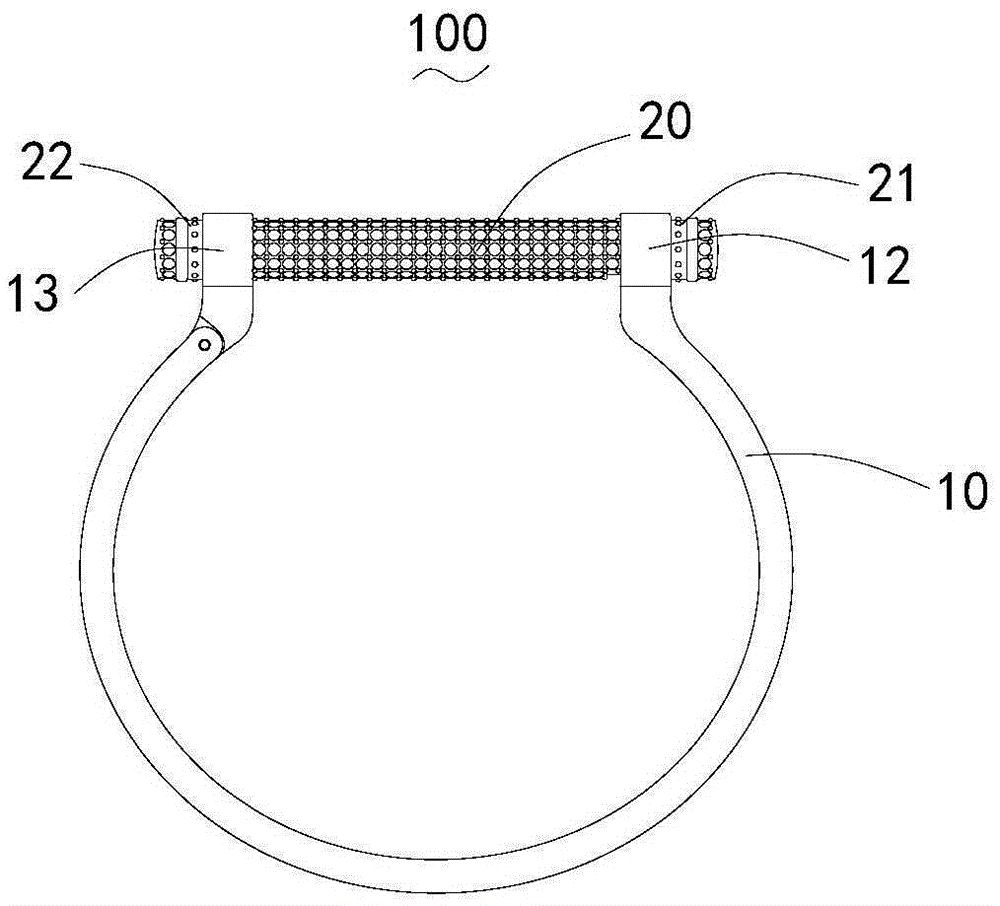

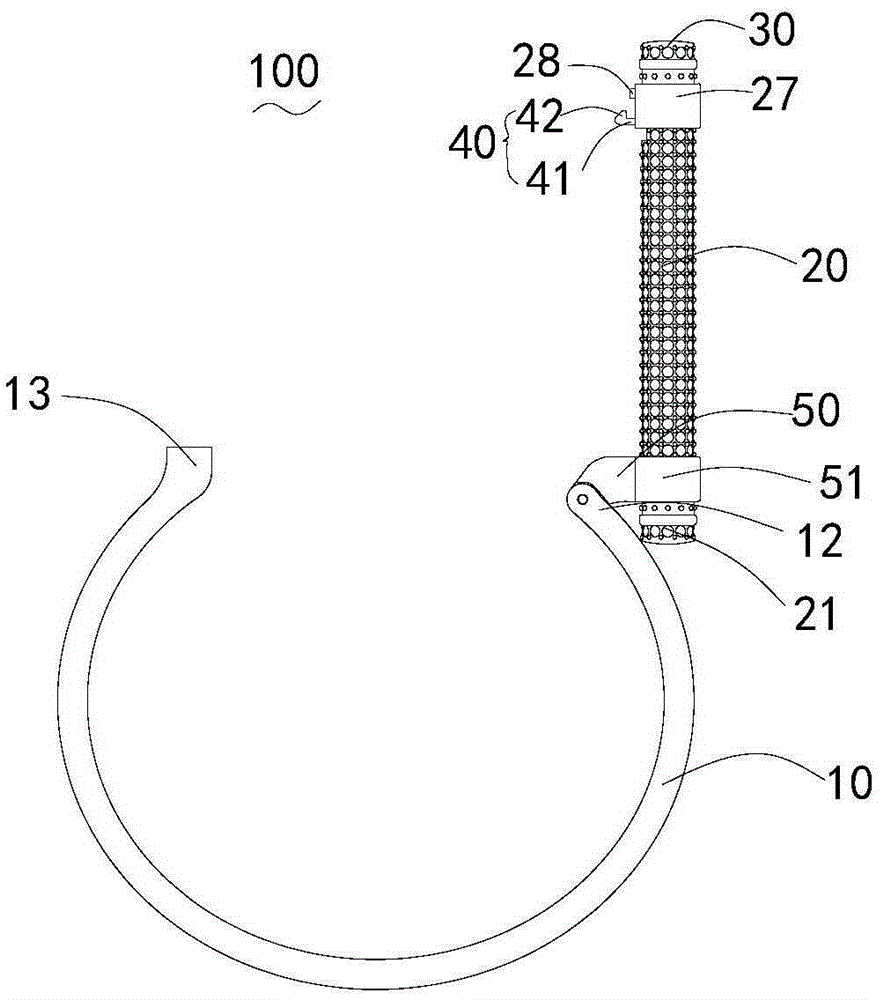

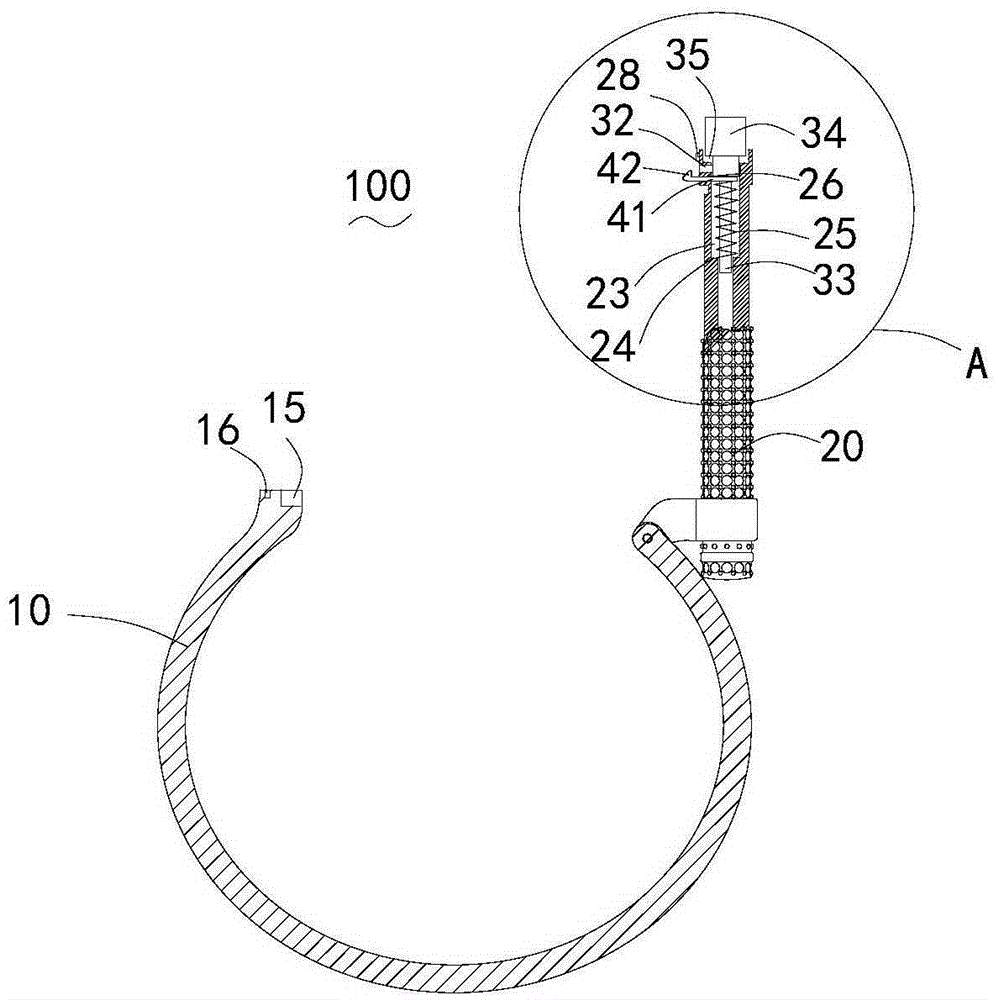

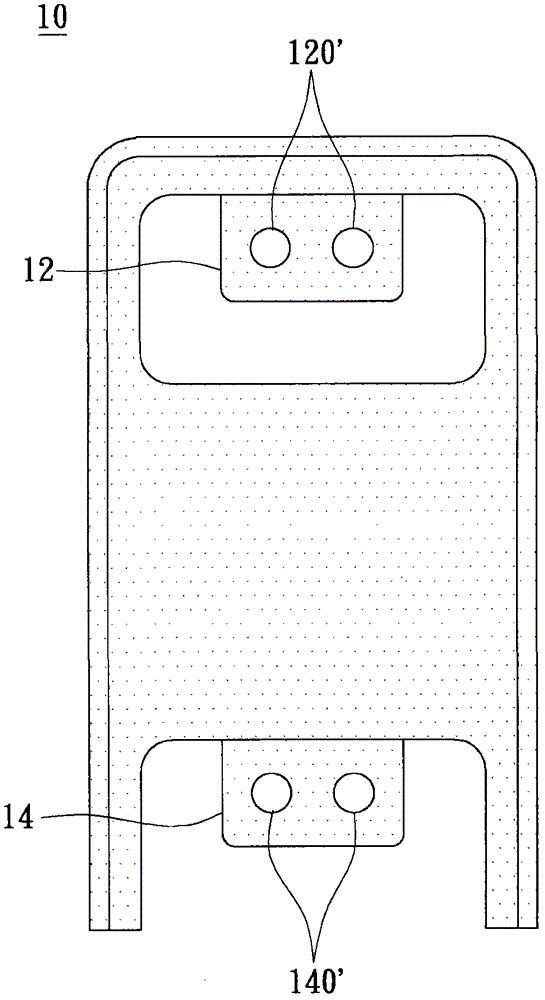

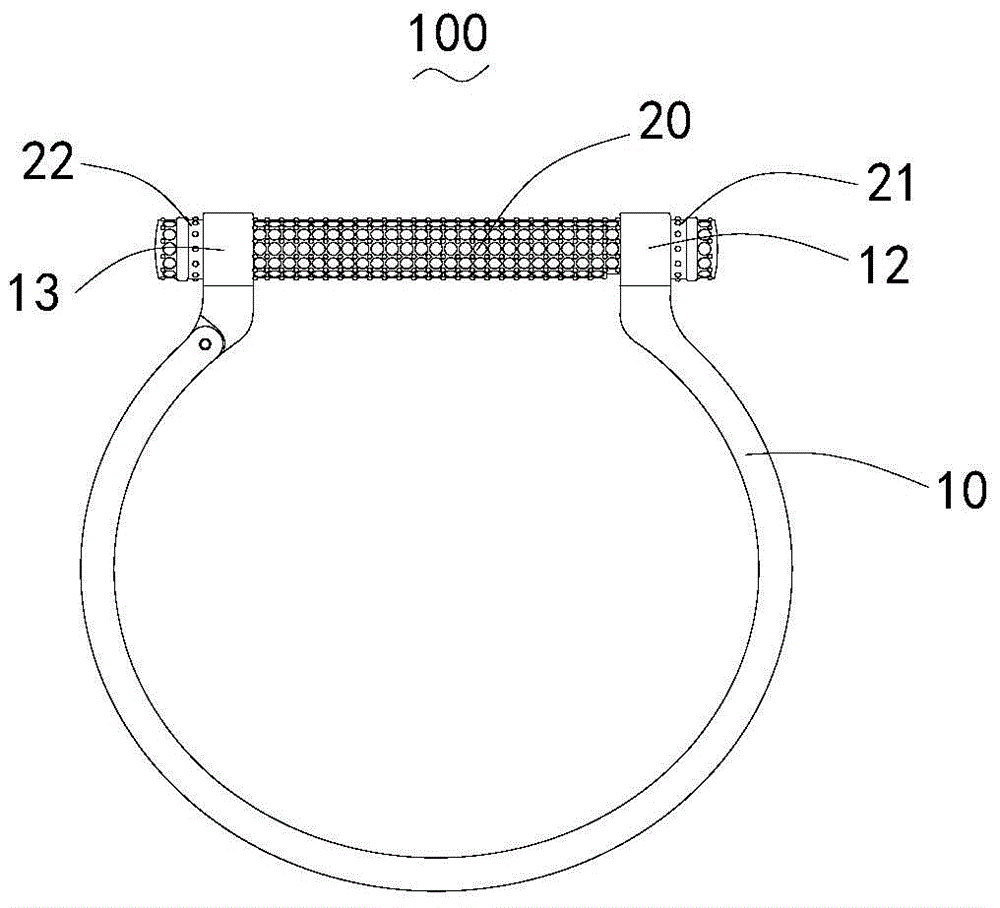

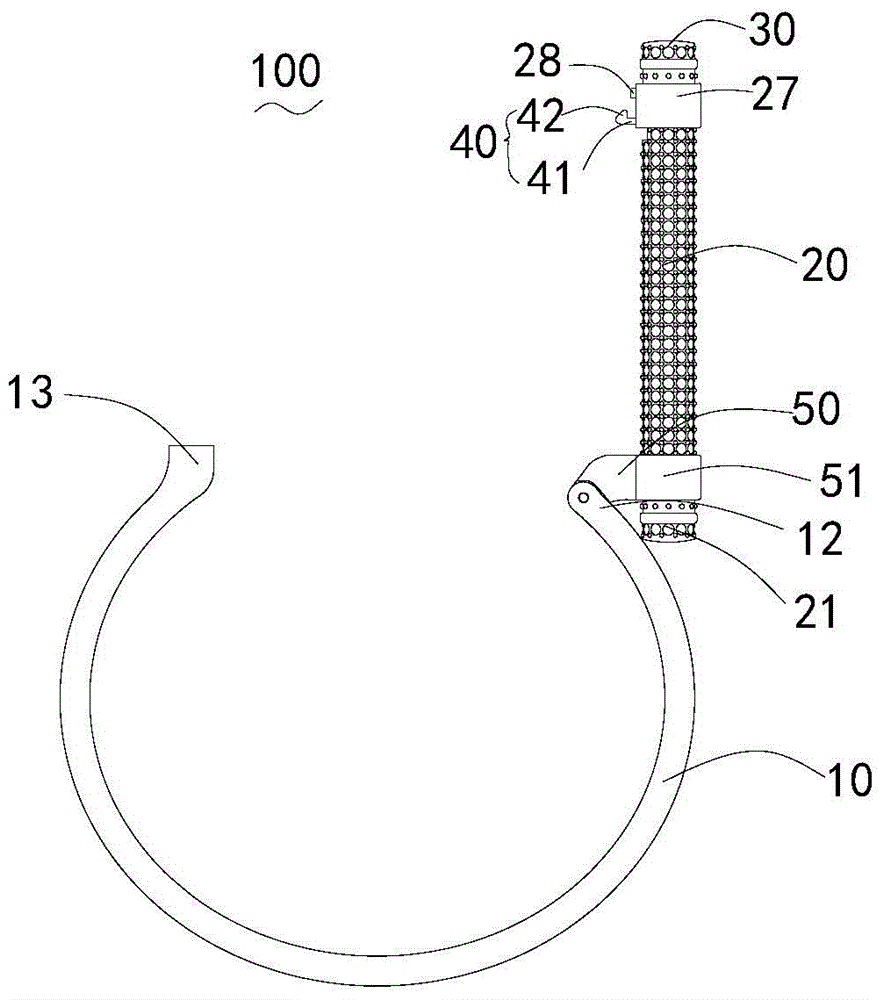

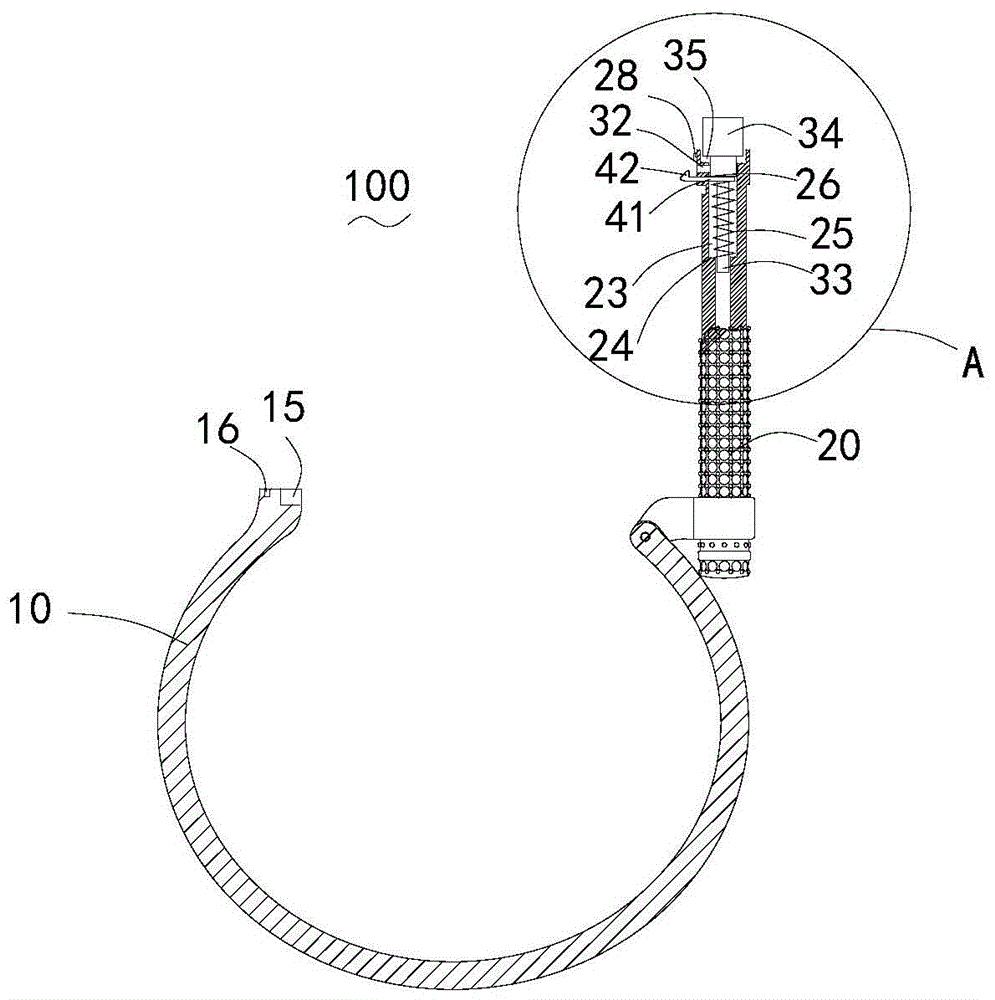

Bracelet

ActiveCN105380359AExquisite appearanceAppearance does not affectBraceletsWrist-watch strapsEngineering

Owner:DONGGUAN YOUSHI IND

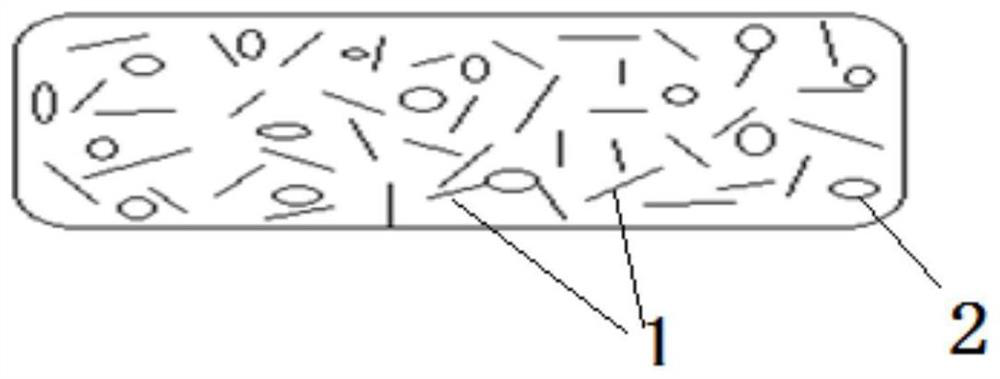

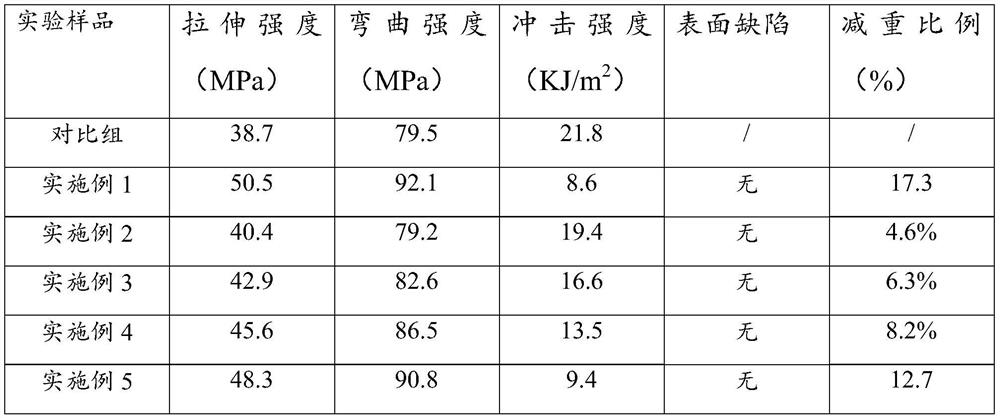

A kind of spray-free plastic and preparation method thereof

The invention discloses a spray-free plastic and a preparation method thereof. Wherein, the spray-free plastic includes the following components by mass: spray-free plastic, which comprises the following components by mass: 40-90 parts of ABS resin, 5-30 parts of AS resin, 1-10 parts of pearl powder, aluminum silver 0.5-10 parts of slurry, 2-25 parts of mineral powder, 0.5-5 parts of dispersant, 0.5-10 parts of foaming agent, 2-10 parts of foaming agent, 0.3-5 parts of antioxidant, 0.2-0 parts of coupling agent 2 servings. The present invention allows the foaming agent to generate a number of tiny bubbles to arrange the pearl flakes and aluminum-silver paste flakes in disorder, so that the outer surface of the plastic product prepared by injection molding using the spray-free plastic of the present invention completely eliminates or greatly reduces flow lines Surface defects such as welding lines or bright and dark lines have excellent physical properties, and can make the surface of plastic products produce a metal texture effect that is closer to the spraying effect.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD

Treatments to Form Composite Surfaces

ActiveCN103255461BNo risk of damageAppearance does not affectSurface reaction electrolytic coatingAnodizingMetal

The invention relates to a treatment method for forming a composite surface. The method comprises the following steps: providing a workpiece, wherein the workpiece is an aluminum-containing metal shell, and comprises an outer surface and an inner surface; carrying out a machine processing treatment on the workpiece; forming a fixation part on the inner surface of the workpiece, forming at least an electrode conduction hole on the fixation part, carrying out a primary anode treatment on the workpiece, forming an oxidation film with a first color on the surface of the workpiece, adopting the machine processing manner to remove part of the oxidation film on the fixation part, and removing part of the oxidation film on the outer surface of the workpiece; carrying out a secondary anode treatment on the workpiece, and forming an oxidation film with a second color on a position on the outer surface of the workpiece, wherein the oxidation film is removed from the position on the outer surface of the workpiece; and removing the fixation part. With the treatment method, a surface of a metal workpiece can obtain oxidation films with different colors.

Owner:CATCHER TECH

bracelet

ActiveCN105380359BExquisite appearanceAppearance does not affectBraceletsWrist-watch strapsEngineering

Owner:DONGGUAN YOUSHI IND

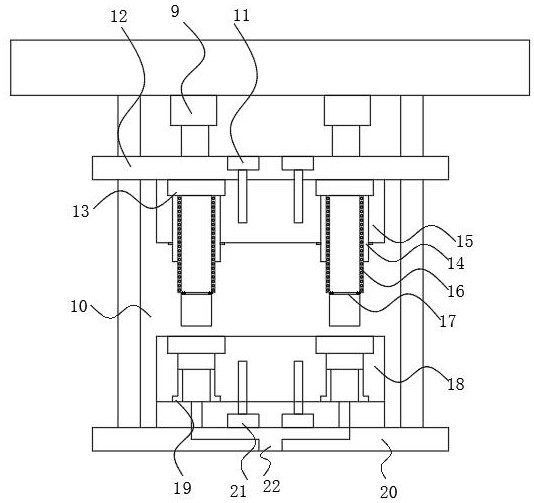

Processing equipment adapting to thickness change and used for automobile special-shaped plastic covering part processing

InactiveCN112123682AAppearance does not affectPrevent shrinkageHeat transmissionMechanical engineering

The invention discloses processing equipment adapting to thickness change and used for automobile special-shaped plastic covering part processing, and relates to the technical field of automobile plastic covering part injection molding processing. The equipment particularly comprises a cooling pool, an injection mold mechanism, a heat transmission extrusion mechanism and a disc type continuous drying mechanism, a conveying belt is arranged at the middle end of the cooling pool, a through groove is formed in the surface of a piston injection molding mechanism, a piston is arranged in a piston cavity, the disc type continuous drying mechanism is arranged on one side of the surface of a shell, a bin body is arranged on the surface of the disc type continuous drying mechanism, material bafflesare fixed to the periphery of a second drying disc, and a discharging port is formed in the bottom of the bin body. According to the equipment, by arranging the cooling pool, workpieces, the appearance of which is required to have no sink marks but the interiors of which are allowed to have shrinkage holes, can be quickly soaked in frozen water after mold stripping, so that the workpieces are cured and cooled in a short time, and the sink marks are prevented from being generated; and this method is relatively effective for products with relatively large wall thicknesses.

Owner:CHONGQING TECH & BUSINESS UNIV

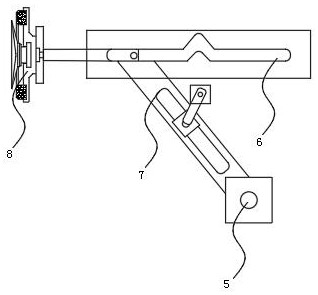

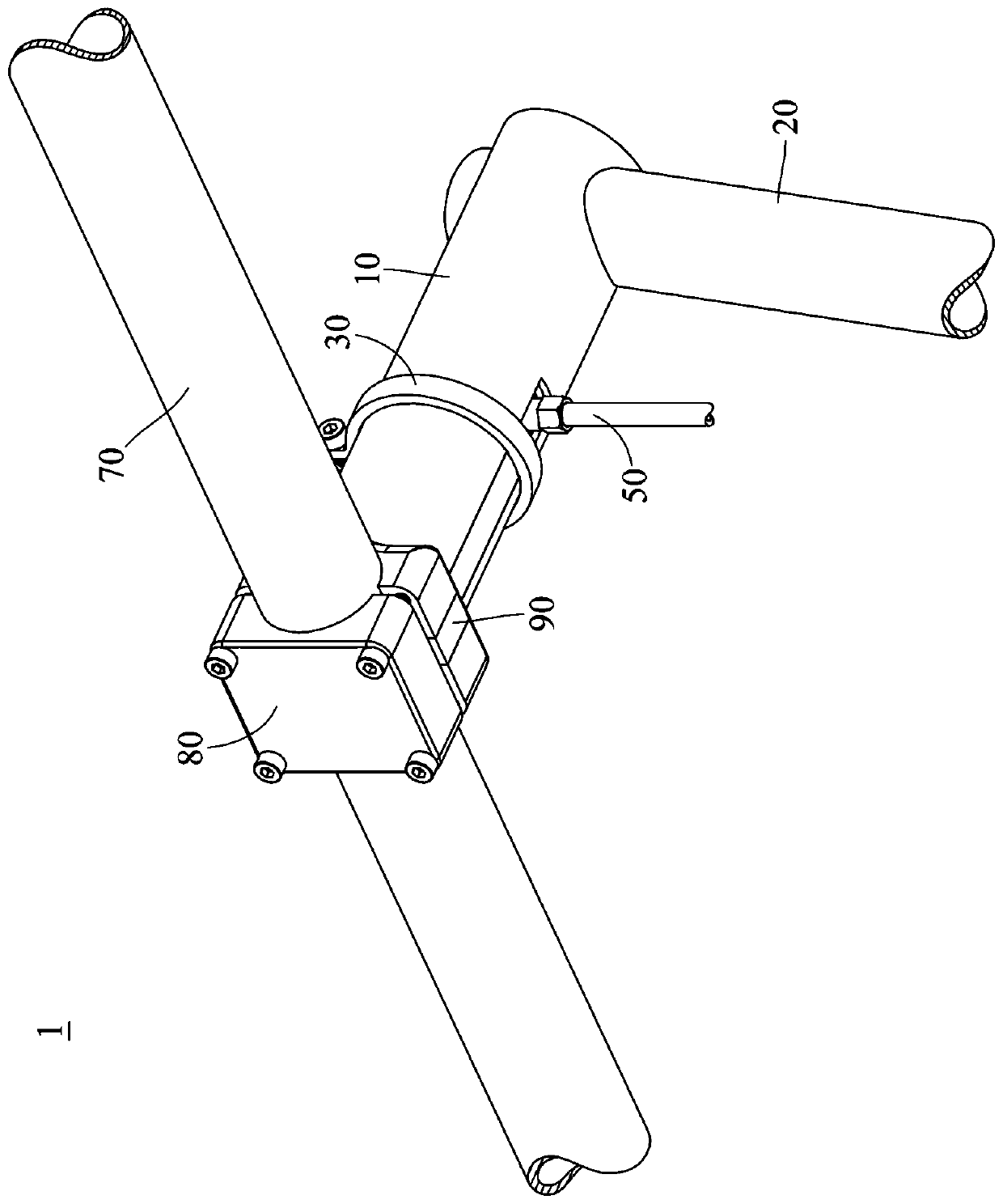

A vehicle head assembly with an anti-brake locking device

InactiveCN110857133ADifficult to observeAppearance does not affectBraking action transmissionSteering deviceEngineeringControl theory

A vehicle head assembly with an anti-brake locking device includes a driver's grip, a faucet column, a faucet vertical rod and an anti-brake locking device, wherein opposite ends of the faucet vertical rod are fixed to the driver's grip and the faucet column, the faucet vertical rod has an accommodating space; and the anti-brake locking device is arranged in the accommodating space of the faucet vertical rod. Since the anti-braking locking device is arranged in the accommodating space of the faucet vertical rod, the anti-braking locking device cannot be easily observed from the appearance of abicycle, so the anti-braking locking device does not affect the appearance of the bicycle, so the bicycle's aesthetic sense is maintained.

Owner:TEKTRO TECH

Protective device used for casting

InactiveCN107486540AAppearance does not affectGuarantee the appearance qualityFoundry mouldsFoundry coresMaterials scienceCasting

The invention discloses a protection device for castings, which comprises a casting body, on which a process gas pipe and a process riser are arranged, wherein, the casting body is provided with a process gas pipe and a process riser correspondingly A conical boss, the said conical boss is arranged below the process gas pipe and the process riser. The above protection device for castings can effectively solve the problem of the appearance of castings with meat. When the castings with conical bosses are cleaned after the process air pipe and process riser, due to the protective effect of the conical bosses, the process air pipe and process The meat of the riser band does not affect the appearance of the casting. After the process air hole and the process riser are cleaned, the remaining conical boss can be ground with a grinder. Not only is the structure simple and easy to implement; it can also guarantee the appearance quality of casting products.

Owner:许斌

Multifunctional illuminating lamp for vehicle

ActiveCN111928155AImprove lighting effectsIncrease flexibilityVehicle interior lightingElectric circuit arrangementsPickup truckEngineering

The invention discloses a multifunctional illuminating lamp for a vehicle. The lamp comprises a lamp mounting base and an illuminating lamp body, the lamp mounting base is of a box-shaped structure and can be mounted on a metal plate of an automobile, the illuminating lamp body comprises a lamp shell and an illuminating light-emitting face arranged on the lamp shell, the lamp shell is detachably mounted on the lamp mounting base, and a light source is arranged in the lamp shell and located on the inner side of the illuminating light-emitting face. By the adoption of the technical scheme, wasteis turned into wealth, when the illuminating lamp is mounted on the lamp mounting base, the illumination light-emitting surface can provide conventional illumination, when the illuminating lamp is detached from the lamp mounting base, the illuminating lamp can be used as a flashlight, any place needing to be illuminated is illuminated, the LED lamp is good in lighting effect, extremely high in flexibility, attractive, elegant, compact in structure, convenient to store and use, extremely high in practicability, particularly suitable for being installed in a trunk of a car, a trunk of an SUV and an MPV, a pickup truck, a container of a truck and the like, wide in application range, and does not influence the appearance.

Owner:CHONGQING REBO LIGHTING & ELECTRONICS

Lens assembly and electronic equipment

ActiveCN112887562AImprove camera functionImprove user experienceTelevision system detailsColor television detailsPhysicsEngineering

The invention discloses a lens assembly and electronic equipment, and relates to the technical field of electronic products. A lens assembly comprises a fixing module and a lens module. The fixing module is detachably connected to the electronic equipment; the lens module comprises a lens body, the lens body is connected to the fixing module, the lens body and a camera of the electronic equipment are arranged in an overlapped mode under the condition that the fixing module is connected to the electronic equipment, and the lens body is electrically connected with the electronic equipment. The electronic equipment comprises an equipment body, a camera is arranged on the equipment body, a lens assembly is detachably installed on the equipment body, and a lens body of the lens assembly and the camera are arranged in an overlapped mode. The problem that in the prior art, the camera shooting function and the appearance of the electronic equipment cannot be coordinated is solved.

Owner:VIVO MOBILE COMM CO LTD

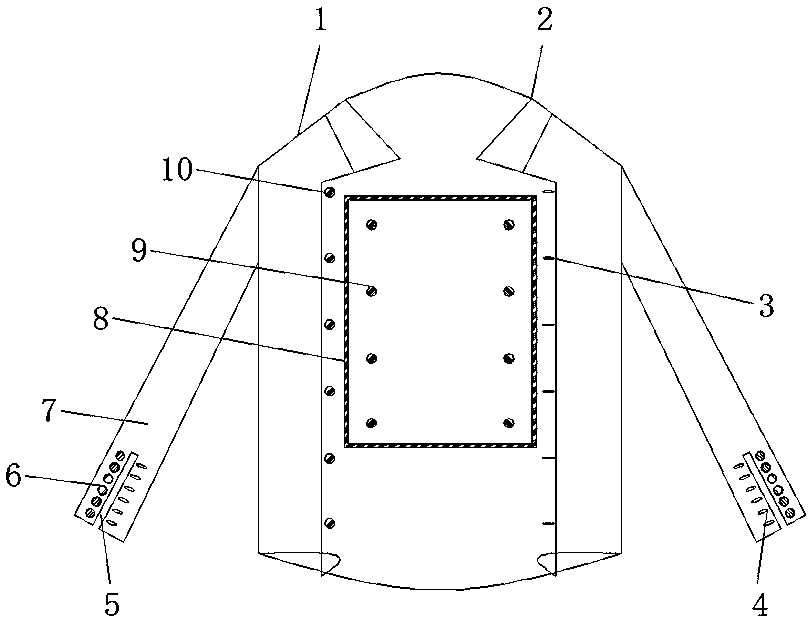

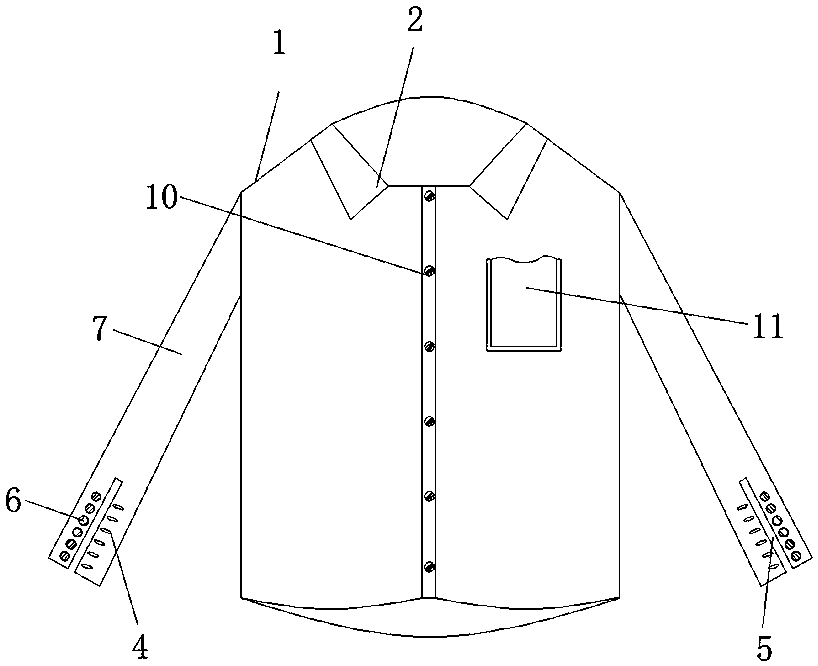

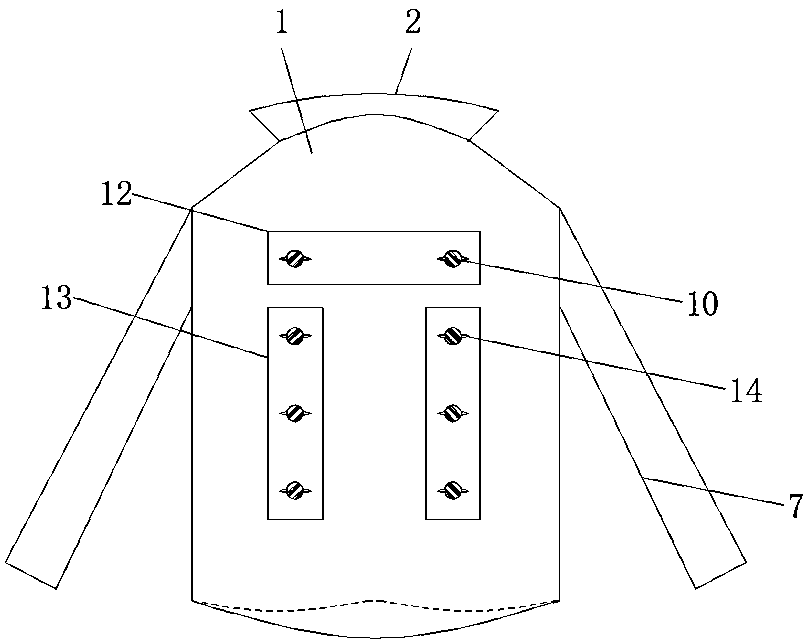

Garment with double-layer sweat absorbing function

The invention discloses a garment with a double-layer sweat absorbing function. The garment comprises a garment body, a sweat absorbing layer, first shielding cloth and second shielding cloth. A collar is installed on the upper end face of the garment body, a pocket is sewn to one side of the outer surface of the garment body, sleeves are installed on the two side faces of the garment body, forksare formed in the tail ends of the sleeves, sleeve buttons are installed on one sides of the forks, sleeve button holes are formed in the other sides of the forks, first buttons are installed on the garment body, first button holes are formed in the side, deviating from the first buttons, of the garment body, second button holes are formed in the back face of the garment body, the first shieldingcloth and the second shielding cloth are sewn to the second button holes, the sweat absorbing layer is installed on the inner surface of the garment body through the second buttons, and the second buttons are installed on the surface of the sweat absorbing layer. The garment has the advantages that sweat flowing from the back of the human body is absorbed, and the sweat absorbing layer is convenient to detach and clean.

Owner:HAINING JINCHUAN LEATHER CLOTHING CO LTD

Support frame and stopping structure

InactiveCN102588717BAppearance does not affectEasy to operateRod connectionsStands/trestlesEngineeringSupport plane

A support frame comprises a base, a support column and a movable part, wherein the support column is arranged on the base, and the movable part is movably arranged on the support column. A stopping structure is arranged inside the support column and comprises a lower part, an upper part and a rotary part, wherein the lower part is provided with an insertion hole and two projections convexly arranged on the inner surface of the insertion hole, the upper part is positioned above the lower part in a spaced manner and provided with a circular hole, two first staggered grooves and two stoppers are arranged on the periphery of the circular hole, and the two first grooves are communicated with the circular hole. The rotary part rotates and moves vertically and comprises a body and a plurality of guide teeth, the guide teeth are formed at the lower end of the body in a surrounding manner and arranged in a uniformly spaced manner, an inclined surface is formed at the lower end of each guide tooth, and two abutting portions are convexly arranged on the periphery of the body. Therefore, the movable part can be stopped by the stopping structure.

Owner:SYNCMOLD ENTERPRISE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com