A locking mechanism for a drum washing machine dispenser

A technology of a drum washing machine and a locking mechanism, applied in the field of washing machines, can solve the problems of uneven appearance of the handle of the dispenser, affecting the user's visual experience, large size of the hook, etc., and achieves a simple and beautiful appearance, good elasticity, and good visual experience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

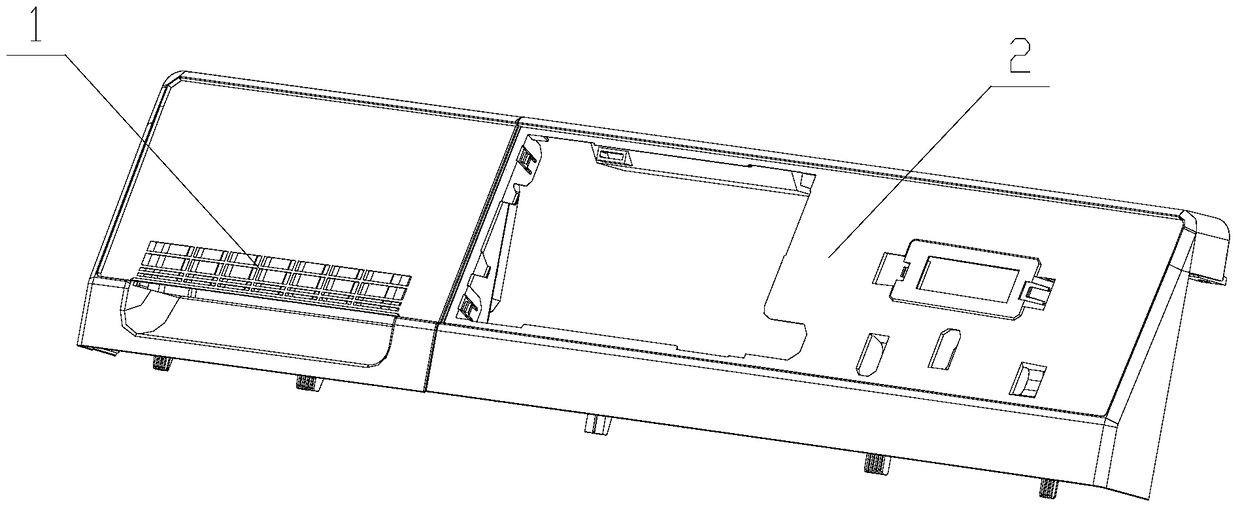

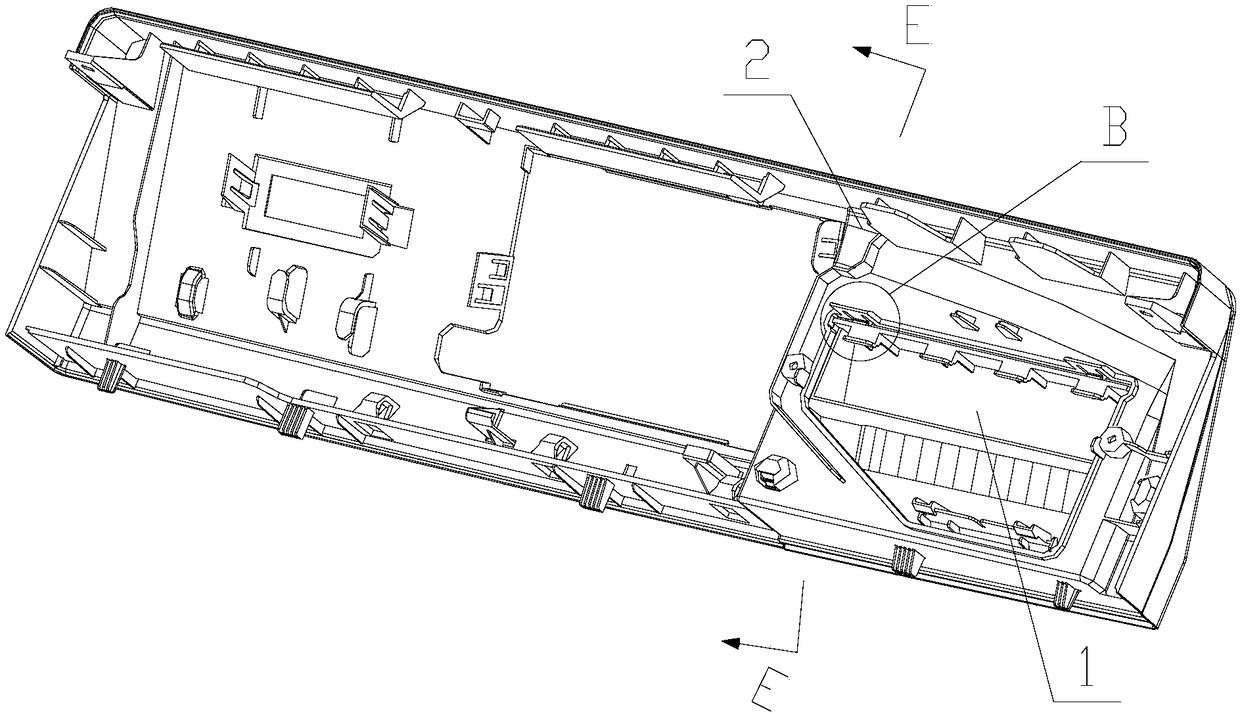

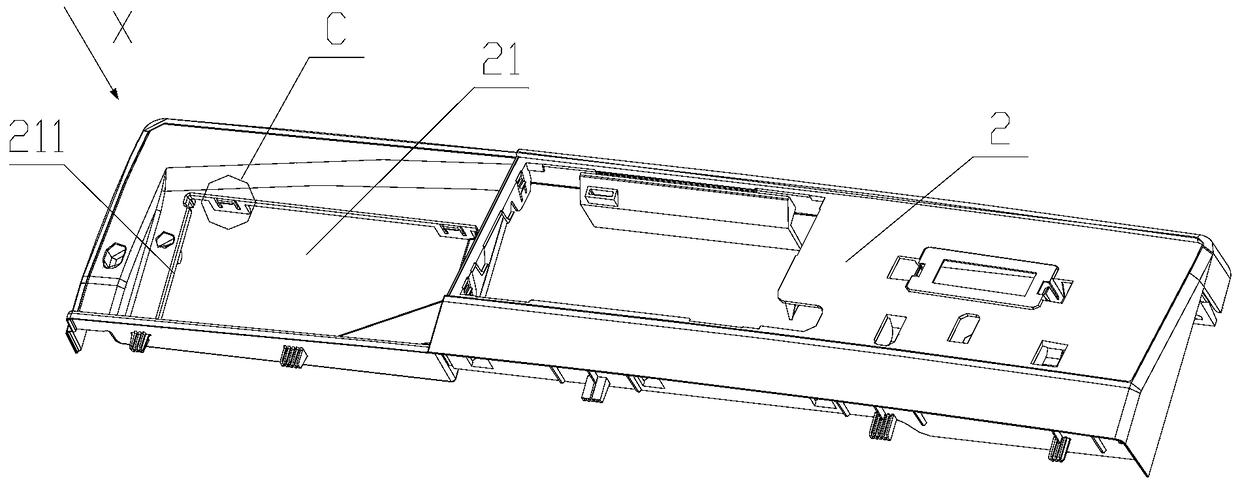

[0027] like figure 1 , figure 2 , Figure 5 and Image 6 As shown, a locking mechanism for a drum washing machine dispenser provided in Embodiment 1 includes a dispenser handle 1 and a main control board 2. The main control board 2 is provided with an assembly port 21, and the shape of the assembly port 21 is It matches the shape of the dispenser handle 1 and is used to install the dispenser handle 1. The dispenser handle 1 is plug-fitted with the main control board 2 through the assembly port 21 . The board surface of the main control board 2 is usually in the vertical direction, and the dispenser handle 1 enters and exits the main control board 2 from the direction perpendicular to the board surface of the main control board 2, which is similar to the drawer and drawer cabinet. In addition, you can also refer to the free coordinate X axis, the dispenser handle 1 is plugged and matched with the main control board 2 along the direction of the X axis.

[0028] A hook 3 is...

Embodiment 2

[0035] like Figure 9 As shown, a locking mechanism for a drum washing machine dispenser provided in Embodiment 2 includes a dispenser handle 1 and a main control board 2 . The difference between embodiment two and embodiment one is:

[0036] The fixed end of the elastic cantilever 31 is connected to the first end of the inverted U-shaped elastic piece 6, and the second end of the inverted U-shaped elastic piece 6 is fixed at the inner edge of the side wall of the assembly port 21 where the end of the guide wall 211 is located. This structure The elastic cantilever 31 and the inverted U-shaped shrapnel 6 improve the elasticity of the hook 3 and the buffering force during the locking process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com