Transportation and erecting all-in-one machine and transportationand erecting construction method of precast component

A prefabricated component, integrated machine technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of inaccurate positioning, difficult installation, and difficulty in accurately adjusting the posture of prefabricated components 2, and achieve precise positioning and improve positioning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

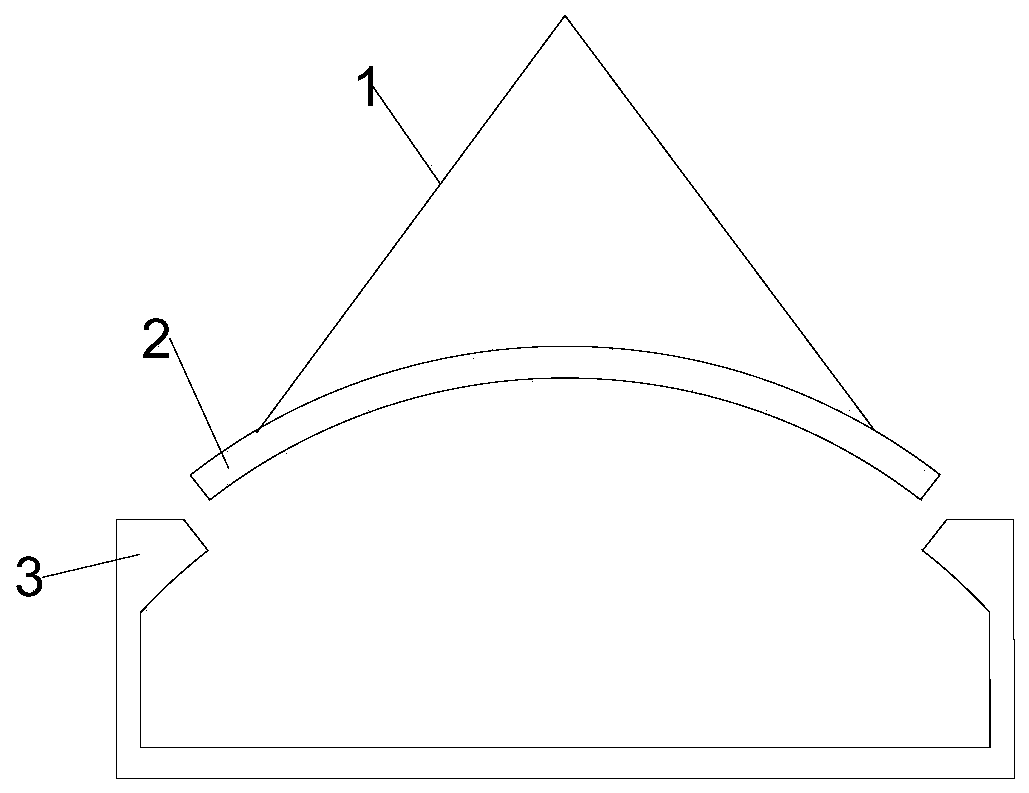

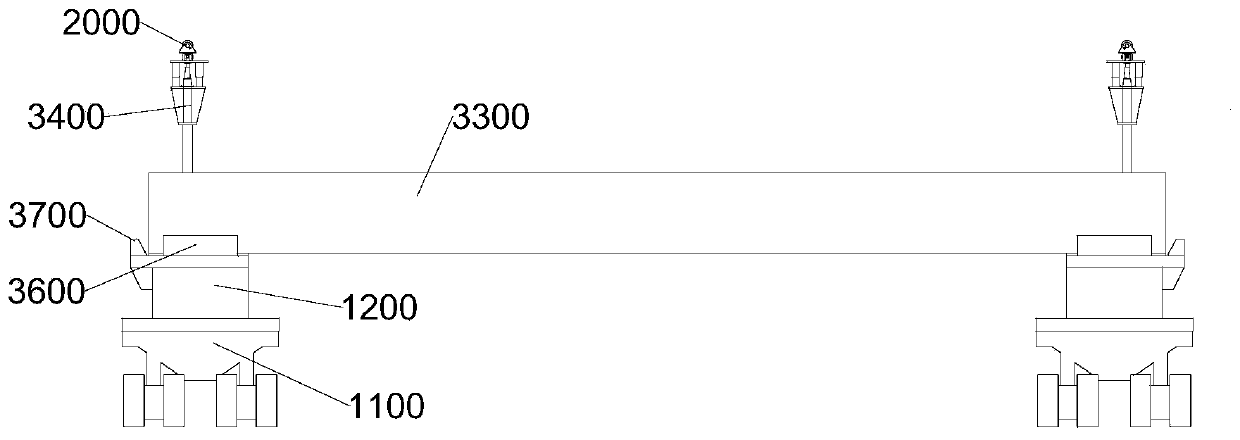

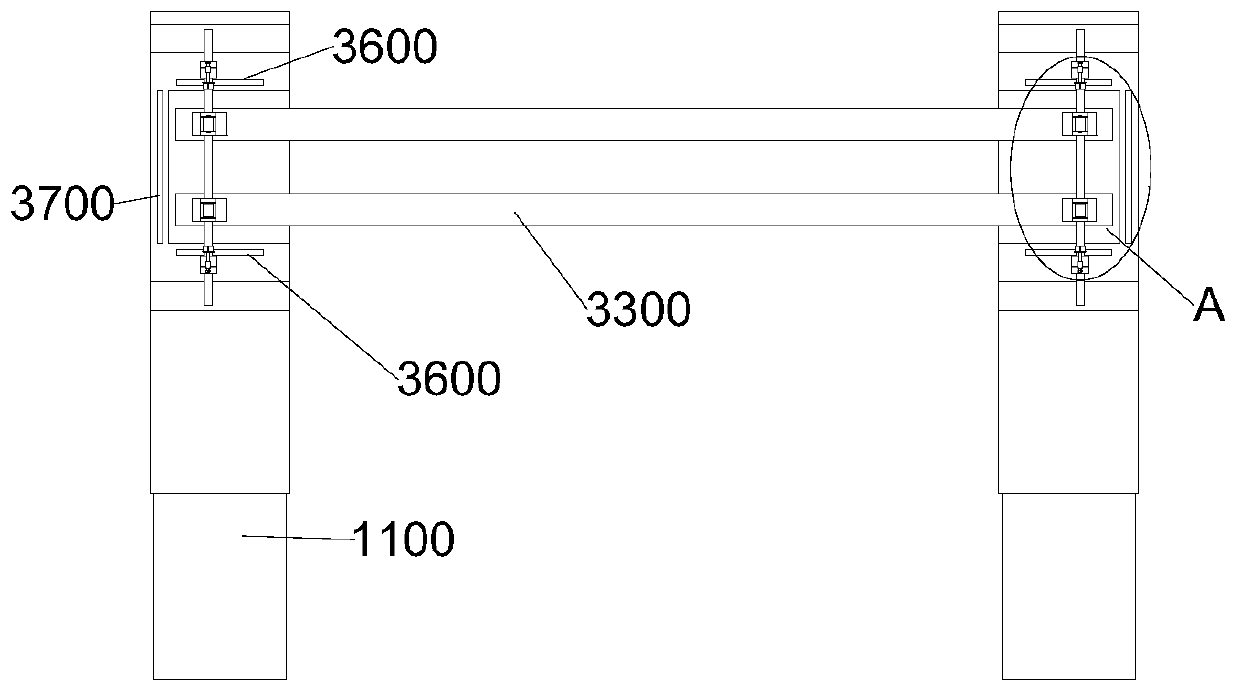

[0077] The core idea of the present invention is to provide an integrated machine for transporting and transporting and positioning and installing prefabricated building components on the plinth, including:

[0078] The coarse adjustment positioning system includes a running mechanism and a first height adjustment mechanism, and the first height adjustment mechanism is arranged on the running mechanism; and

[0079] The fine-tuning positioning system is arranged on the first height adjustment mechanism and includes a horizontal adjustment mechanism and a second height adjustment mechanism, and the second height adjustment mechanism is used to carry the prefabricated components;

[0080] Wherein: the rough adjustment positioning system is used to roughly adjust the prefabricated component to the first position, the first position includes the first horizontal position and the first vertical position, and the traveling mechanism is used for horizontal movement to roughly adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com