Treatment method for forming composite surface

A treatment method and composite surface technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of uncontrollable thickness, damage to the shell, and affect the effect of the second anodic oxidation, etc., and achieve fast processing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

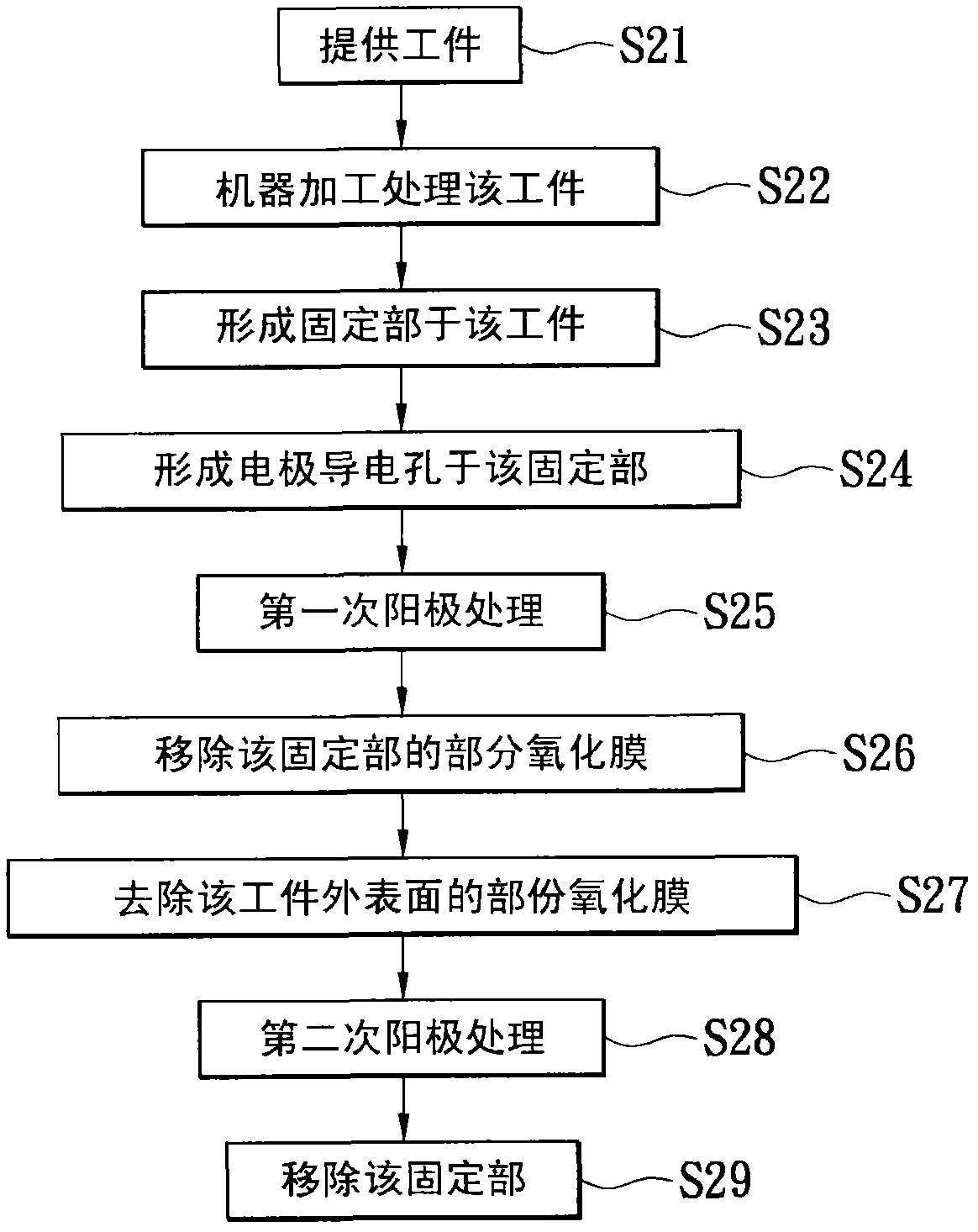

[0029] Please refer to figure 1 , is a flowchart of the processing method for forming a composite surface of the present invention. First, as in step S21, a workpiece is provided, which may be a metal shell containing aluminum, such as aluminum or aluminum alloy, so as to be suitable for anodizing process.

[0030] In order to make the workpiece have a desired shape, such as a casing of an electronic product, as shown in step S22, the workpiece is machined. The machine processing here may include various processing procedures, and the more common precision processing is computer numerical control (Computer Numerical Control, CNC) processing. After the numerical control program instructions are input into the memory of the numerical control system, the computer compiles and calculates, and through the displacement control system, the information is transmitted to the driver to drive the stroke of the motor to cut and process the designed parts. The aforementioned machining tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com