A kind of spray-free plastic and preparation method thereof

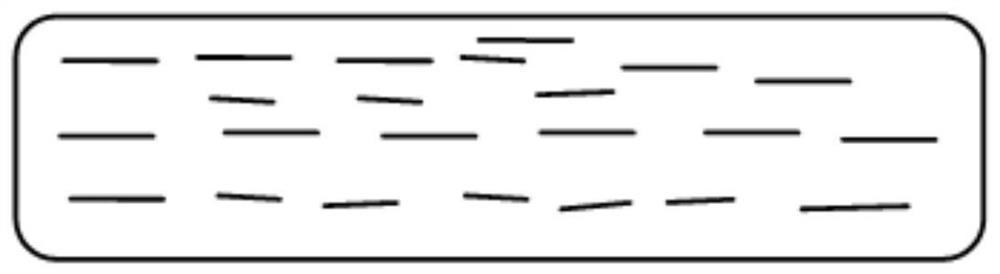

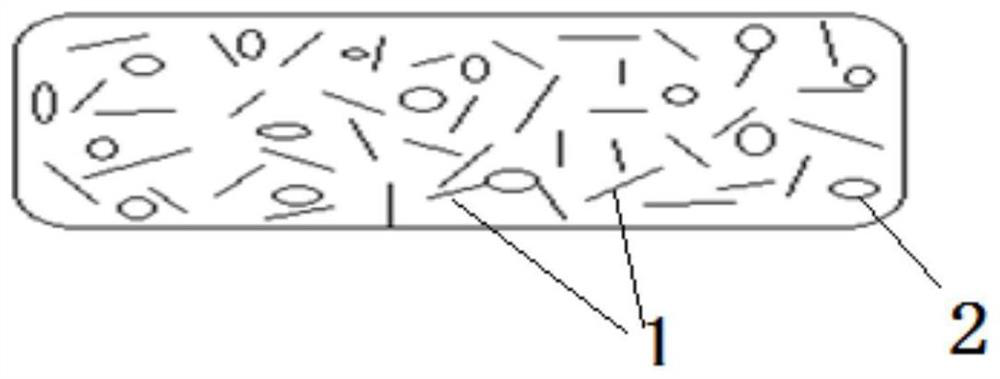

A spray-free and plastic technology, applied in the field of composite materials, can solve the problems of large gaps in visual effect spraying effects, affecting product flow lines, weld lines or bright and dark lines, etc., to eliminate appearance defects and improve tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

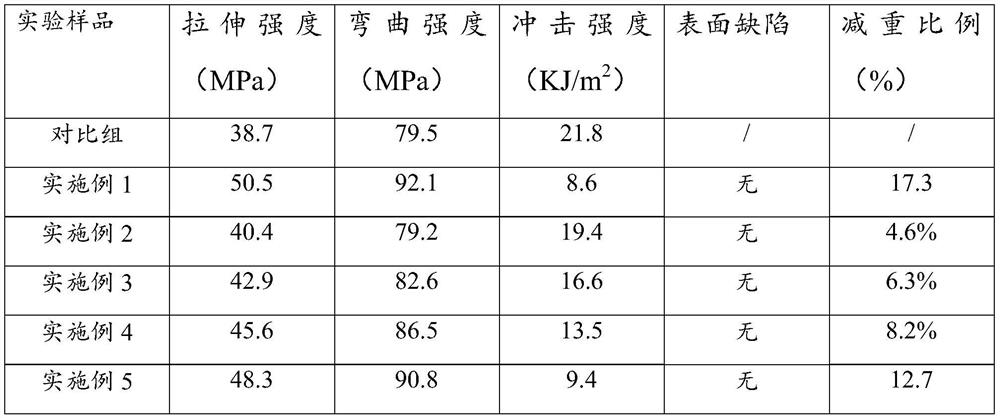

Embodiment 1

[0041] Take 10 parts of pearl powder, 10 parts of aluminum silver paste, 5 parts of dispersant and 5 parts of antioxidant and mix evenly, then add 90 parts of ABS resin, 30 parts of AS resin, 25 parts of mineral powder and 1.8 parts of coupling agent (coupling A total of 2 parts of the foaming agent) were mixed in the mixer for 5 minutes, extruded and granulated by a twin-screw extruder at a working temperature of 230°C to obtain the first granular material; again, 10 parts of the foaming agent, foamed After mixing 10 parts of auxiliary agent and 0.2 part of coupling agent evenly, the second granular material is obtained by extruding and granulating through a single-screw extruder at a working temperature of 80°C; the above-mentioned first granular material and the above-mentioned second The blended particles obtained after the granular materials are uniformly mixed are the spray-free plastics of the present invention.

Embodiment 2

[0043] Take 1 part of pearl powder, 0.5 part of aluminum silver paste, 0.5 part of dispersant and 0.3 part of antioxidant and mix evenly, then add 40 parts of ABS resin, 5 parts of AS resin, 2 parts of mineral powder and 0.12 part of coupling agent (coupling A total of 0.2 parts of the foaming agent) was mixed in the mixer for 3 minutes, and the first granular material was obtained by extruding and granulating through a twin-screw extruder at a working temperature of 180°C; again, 0.5 parts of the foaming agent, foamed After mixing 2 parts of auxiliary agent and 0.08 part of coupling agent uniformly, the second granular material is obtained by extruding and granulating through a single-screw extruder at a working temperature of 100°C; the above-mentioned first granular material and the above-mentioned second The blended particles obtained after the granular materials are uniformly mixed are the spray-free plastics of the present invention.

Embodiment 3

[0045] Take 3 parts of pearl powder, 0.5 part of aluminum silver paste, 1 part of dispersant and 0.5 part of antioxidant and mix evenly, then add 79 parts of ABS resin, 10 parts of AS resin, 5 parts of mineral powder and 0.4 part of coupling agent (coupling A total of 0.5 parts of the foaming agent) was mixed in the mixer for 4 minutes, and the first granular material was obtained by extruding and granulating through a twin-screw extruder at a working temperature of 200°C; again, 1.5 parts of the foaming agent, foamed After mixing 3 parts of auxiliary agent and 0.1 part of coupling agent evenly, the second granular material is obtained by extruding and granulating through a single-screw extruder at a working temperature of 90°C; the above-mentioned first granular material and the above-mentioned second The blended particles obtained after the granular materials are uniformly mixed are the spray-free plastics of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com