A kind of manufacturing method of dimming laminated glass

A manufacturing method and laminated glass technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of debonding, light-adjusting film and PVB bubbles, etc., and achieve the elimination of bubbles and degumming, elimination of appearance defects, bonding and appearance effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The content of the present invention will be further described below in conjunction with the accompanying drawings.

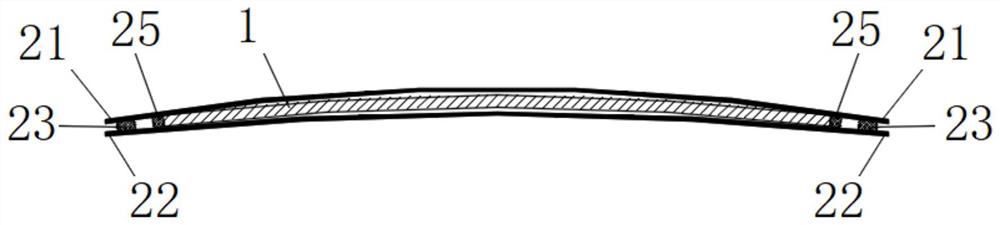

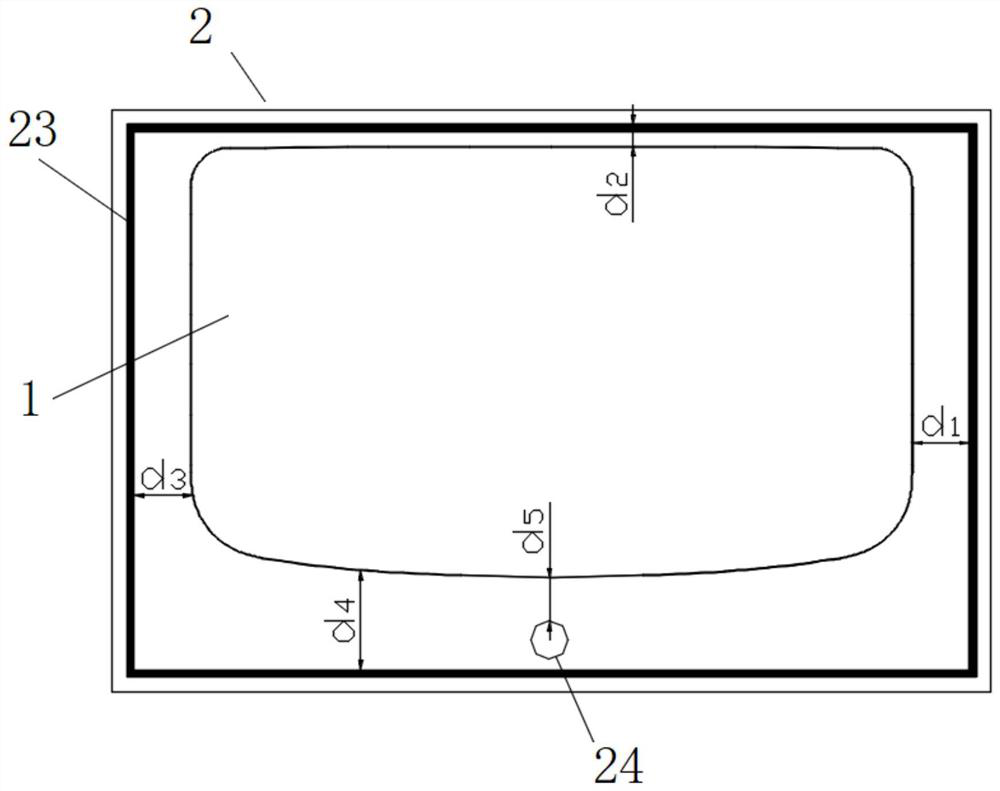

[0030] Such as Figure 1~3 As shown, a method for making a light-adjustable laminated glass according to the present invention is characterized in that it comprises the following steps:

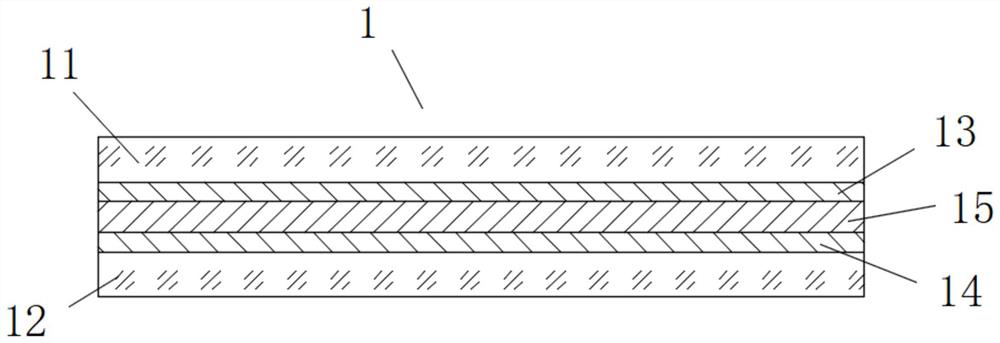

[0031] Step 10: Laminate the first glass substrate 11, the first EVA adhesive layer 13, the liquid crystal dimming film 15, the second EVA adhesive layer 14, and the second glass substrate 12 in order to form a laminated body 1;

[0032] Wherein, the outer peripheral edge of the first glass substrate 11 and the outer peripheral edge of the second glass substrate 12 are substantially flush, and the outer peripheral edge of the liquid crystal dimming film 15 is opposite to the outer peripheral edge of the first glass substrate 11 and the second glass substrate 12. The outer peripheral edge shrinks inward by 5-10mm, and the outer peripheral edge of the first EVA adhesive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com