Organic electroluminescent panel and its mfg. method

A luminescent and organic technology, applied in the field of organic electroluminescent panels and their manufacturing, can solve problems such as adverse effects on appearance, increased product costs, and reduced yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

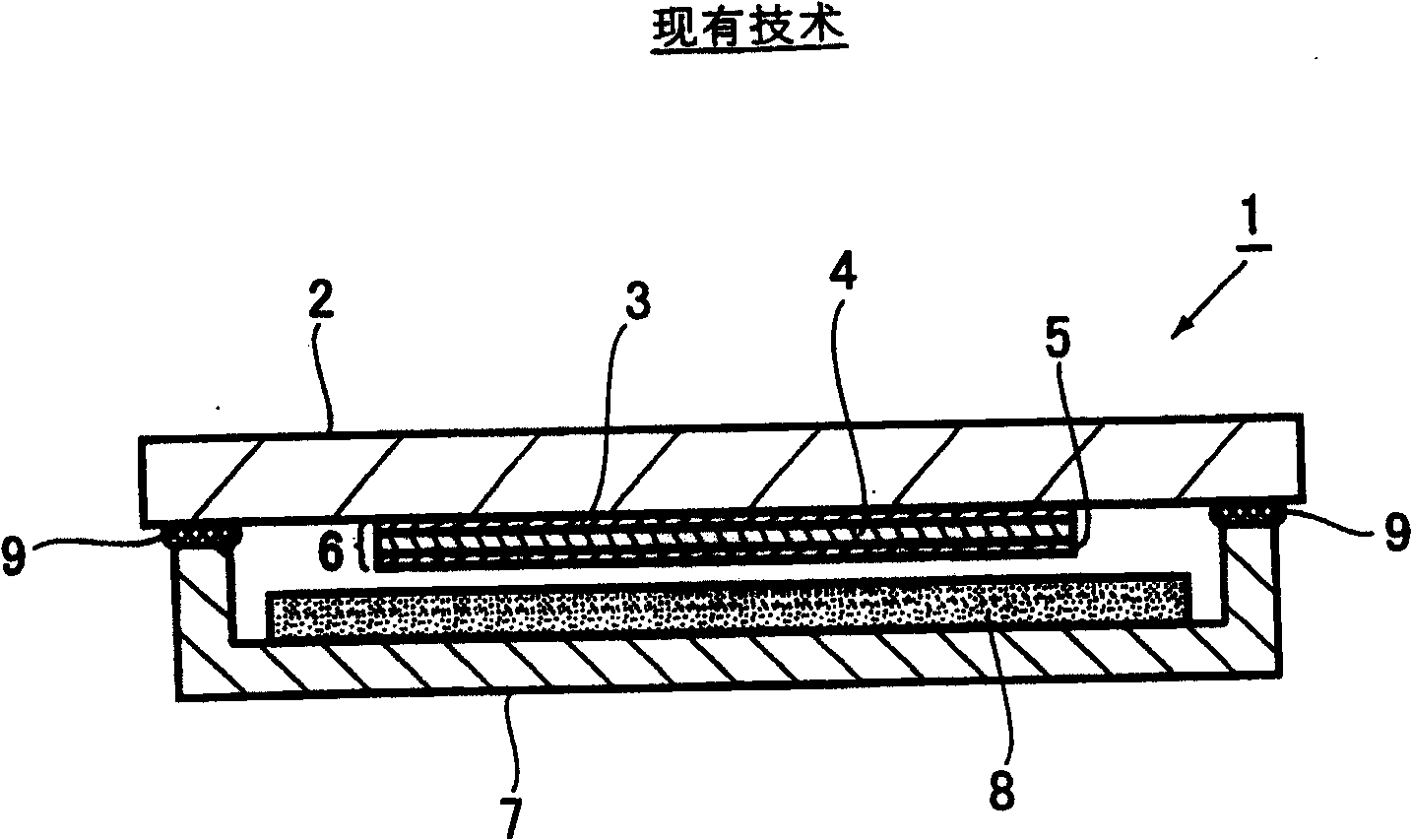

Problems solved by technology

Method used

Image

Examples

Embodiment

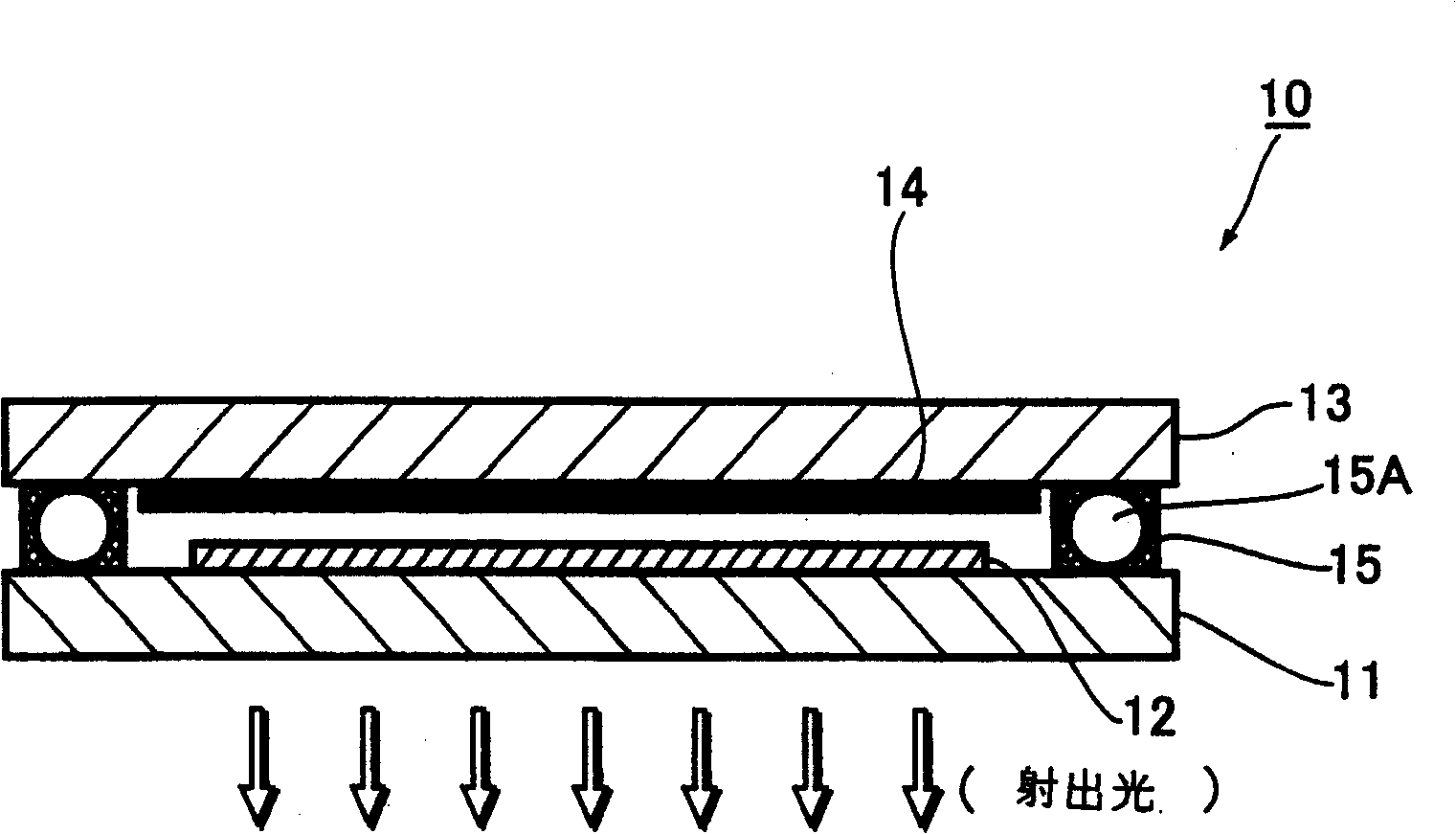

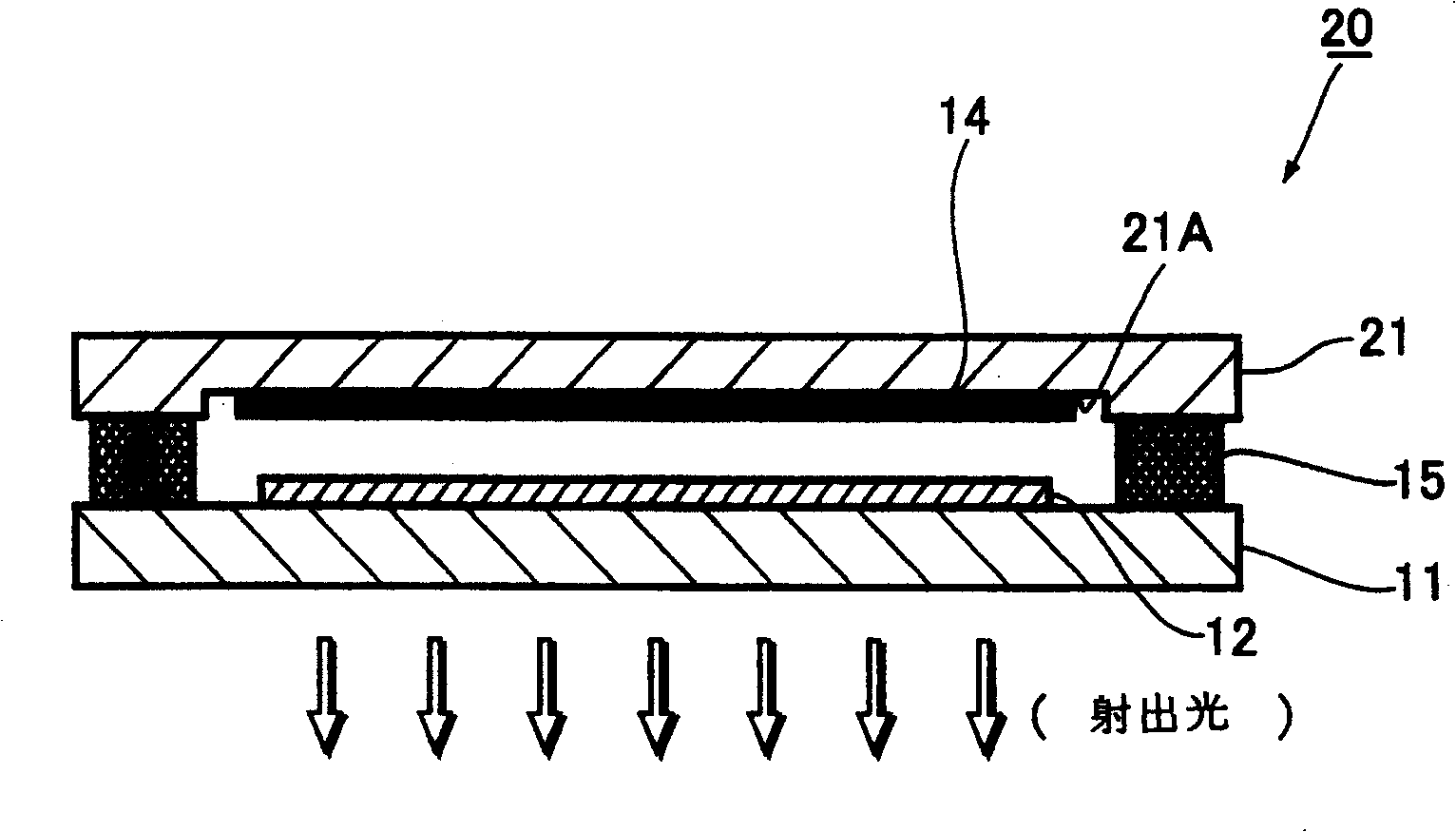

[0041] Hereinafter, as an embodiment of the present invention, specific examples related to the constituent members of the above-mentioned embodiment will be given.

[0042] [Drying unit 14] As the drying unit 14, a physical desiccant (zeolite, silica gel, carbon, carbon nanotube, etc.), a chemical moisture absorbent described later, an organic metal complex dissolved in a petroleum solvent (toluene, dihydrogen, etc.) can be used. Monomers such as desiccants such as toluene, aliphatic organic solvents, etc.) can also be used as hygroscopic molded articles shown below.

[0043] The hygroscopic molded article is a molded article in which a hygroscopic agent is dispersed in a resin component (binder). As the hygroscopic agent, any substance may be used as long as it has a function of at least absorbing moisture, but a compound that can chemically adsorb moisture and maintain a solid state even after absorbing moisture is particularly preferable. Examples of such compounds includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com