Protective device used for casting

A protection device and casting technology, applied in the direction of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of lack of meat in appearance, improper operation, uneven casting surface, etc., to ensure the appearance quality, simple structure, and easy to realize Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

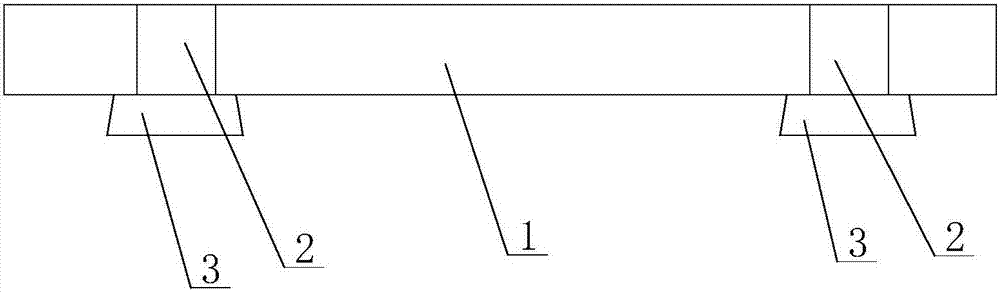

[0011] see figure 1 as shown, figure 1 It is a structural schematic diagram of the protective device for castings provided in Embodiment 1 of the present invention.

[0012] In this embodiment, a protection device for castings includes a casting body 1, on which several process risers 2 are arranged, and on the casting body 1 corresponding to the process risers 2, conical protrusions are arranged. Platform 3, the conical boss 3 is fixed below the process riser 2. The conical boss 3 is small at the top and large at the bottom, the diameter of its top surface is 45mm, the diameter of the bottom surface is 50mm, and the height is 15mm. The diameter of the top surface of the conical boss 3 is larger than the inner diameter of the process riser 2 .

[0013] Before the casting body 1 is manufactured, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com