Structure for preventing soft plastic appearance from being pulled to be sunken

A technology of concave structure and soft rubber, which is applied in the direction of instruments, electronic digital data processing, digital data processing parts, etc., can solve the problems of large deformation of soft rubber, failure to achieve the effect, and sag of soft rubber, and achieve simple structure , easy to process, and avoid the effect of pulling sags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

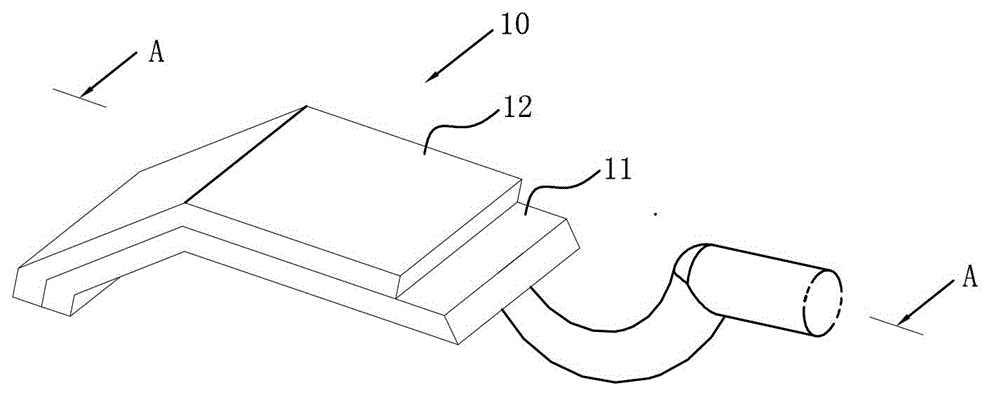

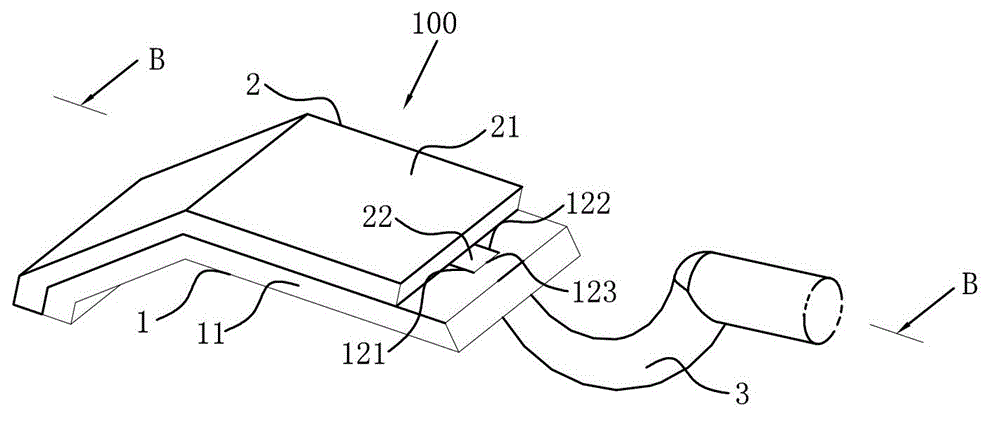

[0019] see image 3 and Figure 4 As shown, the present invention prevents the appearance of the soft rubber from pulling the concave structure, which is applied to the molding of a two-color mold product 100. The inner side of the product 100 is the non-appearance surface, and the product 100 is the outer frame of the notebook computer. :

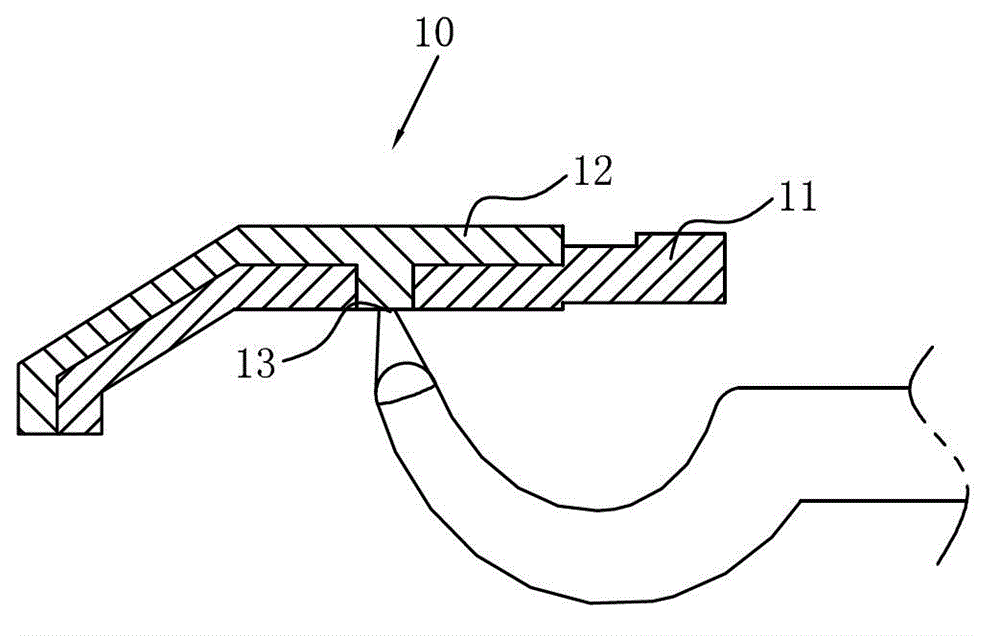

[0020] Hard rubber 1, which includes a hard rubber body 11 and a number of overflow grooves 12 are opened from the surface of the hard rubber body 11 to the hard rubber body 11, and the overflow grooves 12 are located on the non-appearance surface inside the product 100, The overflow groove is a groove surrounded by the first contact surface 121, the second contact surface 122 and the third contact surface 123, the first contact surface 121 is opposite to the second contact surface 122, and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com