Auxiliary strain gauge adhering device

A patch device and strain gauge technology, which is applied in the direction of material gluing, connecting components, mechanical equipment, etc., can solve the problems of high accuracy and achieve high accuracy, high reliability, and high alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

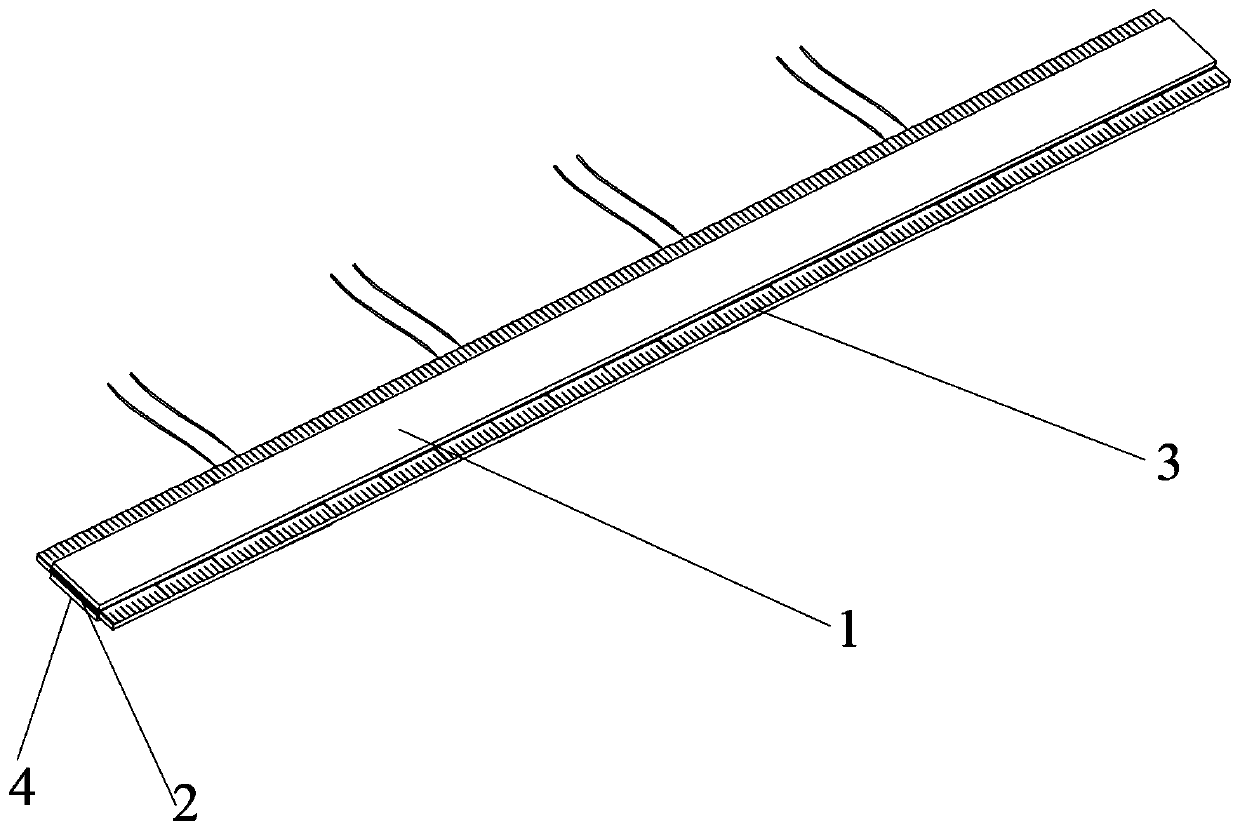

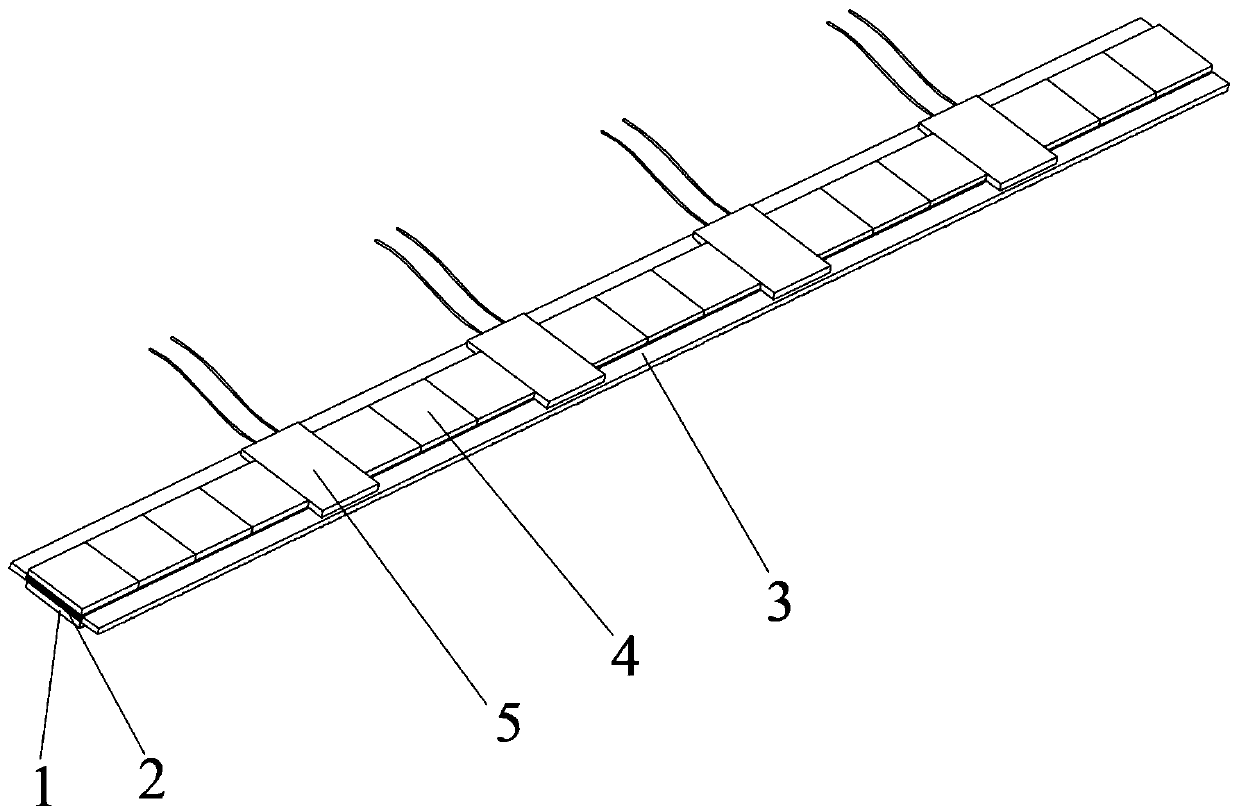

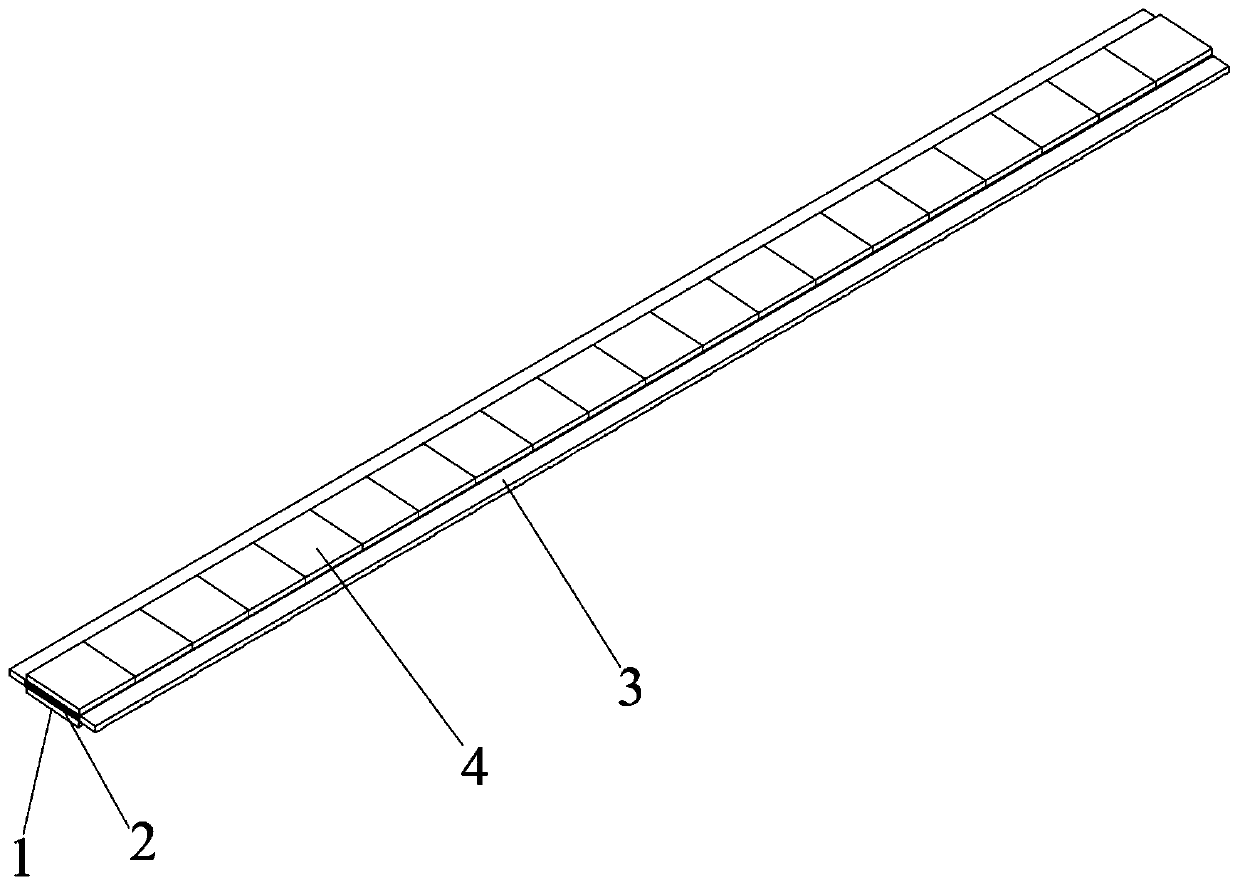

[0013] like figure 1 As shown, a strain gauge auxiliary patching device includes an upper isolation film 1, an adhesive layer 2, a film scale bar 3, a lower isolation film 4 and a strain gauge 5, and is characterized in that the upper isolation film 1 is located at the outermost layer and is connected with the The adhesive layer 2 is bonded and fixed, and the lower isolation film 4 is located at the bottom layer and is also bonded and fixed with the adhesive layer 2. The lower isolation film 4 is a small grid-shaped isolation film. Film scale bars 3 with scales are arranged on both sides of the adhesive layer 2 . The back of the strain gauge 5 is bonded and fixed to the adhesive layer 2 after peeling off the small grid isolation film of the lower layer. The upper isolation film 1 is a monolithic isolation film, and the lower isolation film 4 is a small grid-shaped isolation film. The adhesive layer 2 is sandwiched between the upper isolation film 1 and the lower isolation fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com