Cushion rubber coiling device for tire production

A pad rubber and tire technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of large space occupation, two pads sticking together, easy to pack, etc., and achieve large bearing capacity of the guide rail , Improve production efficiency and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

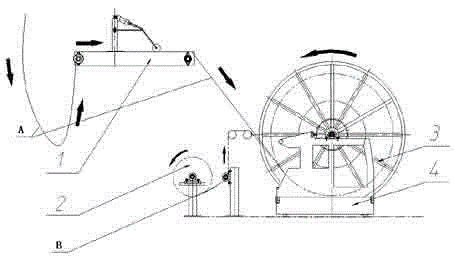

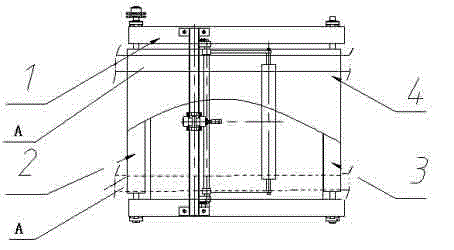

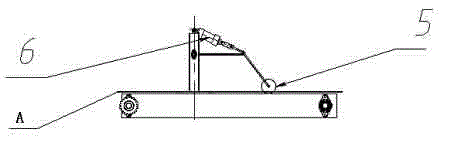

[0033] The specific embodiment of the present invention is described according to accompanying drawing now, as Figure 1~5 as shown,

[0034] A pad rubber rolling device for tire production, comprising: a pad rubber transition device 1, a pad cloth guiding device 2, an I-shaped wheel 3 and a pad rubber rolling trolley 4, the pad rubber transition 1 and the pad cloth guiding device The equipment 2 outputs the pad rubber A and the pad cloth B to the I-shaped wheel respectively, and when the I-shaped wheel rotates, the pad rubber A and the pad cloth B are curled into the I-shaped wheel 3 at the same linear speed , wherein, the cushion rubber B is closer to the axle of the I-shaped wheel 3 than the pad A, that is, the pad B surrounds the pad A from the outside to prevent the gap between the two layers of pad A. sticky. At the same time, the crimping of the I-shaped wheel makes the transportation and storage mode of the pad rubber change from being cut into a single strip to bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com