Crawler belt moving type automatic feeding machine facilitating concentrated material stacking in harbor district

An automatic feeding and mobile technology, which is applied in the direction of conveyors, conveyor objects, loading/unloading, etc., can solve the needs of large-scale storage yards, excessive wear of feeder spiral blades, and stacking area Large and other problems, to achieve the effect of free movement, large stacking radius and fast feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

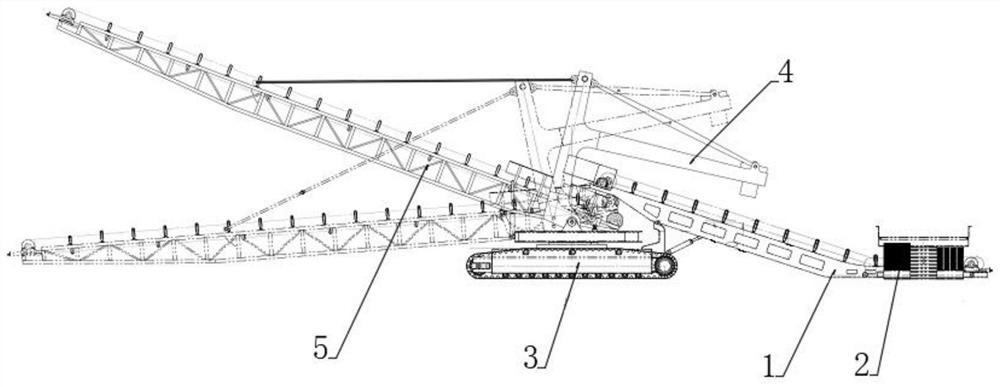

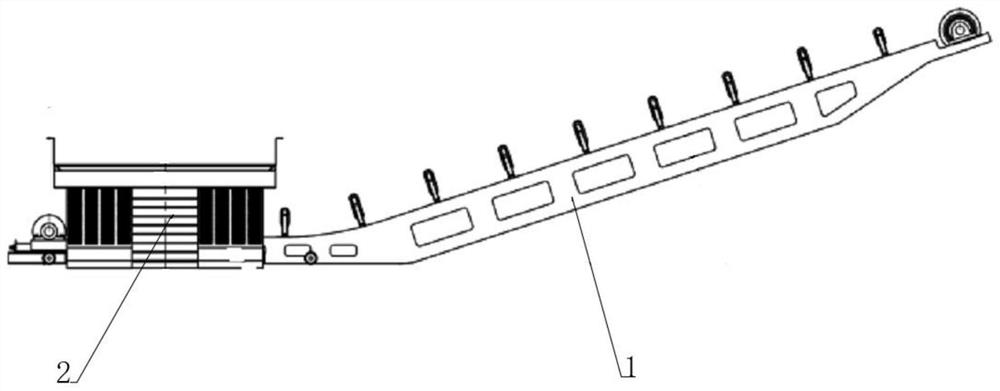

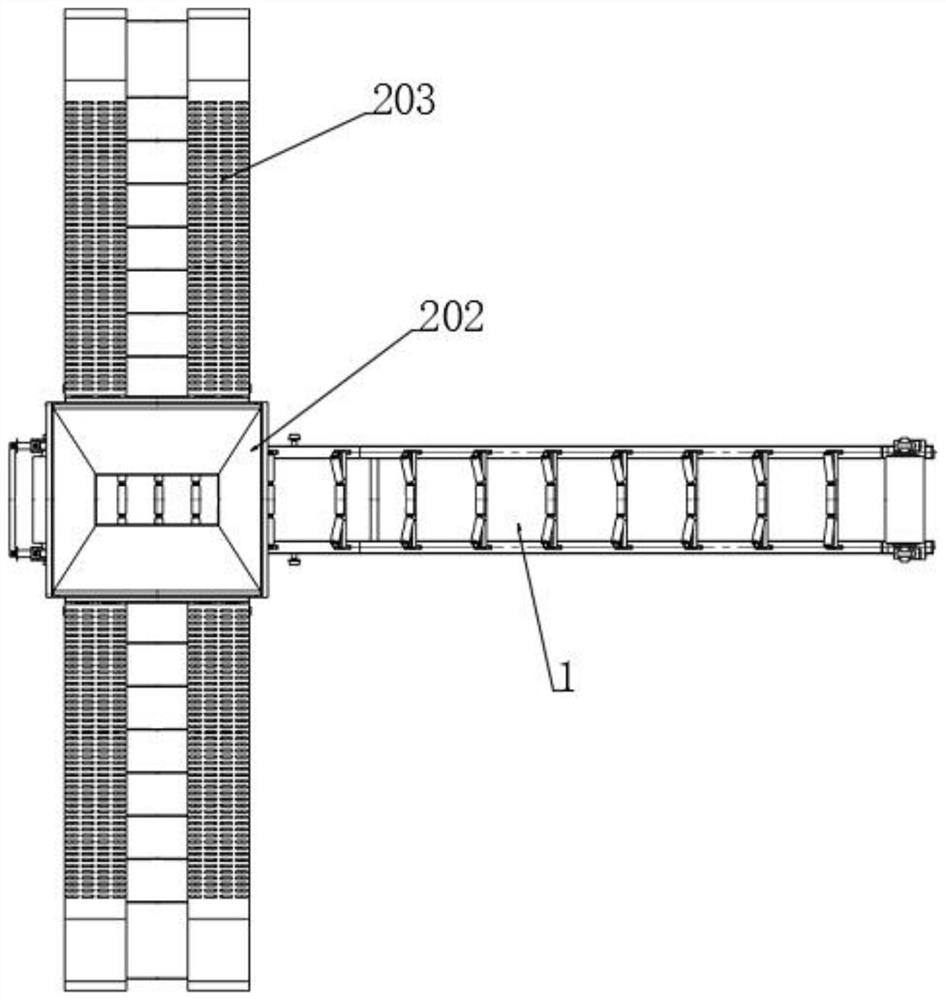

[0041] see Figure 1-4 , a crawler mobile automatic feeding machine that is convenient for centralized stockpiling in the port area, including a feeding mechanism 2, a cantilever feeding belt conveyor 1, a walking mechanism 3, a cantilever discharging belt conveyor 5 and a power control system, and the feeding mechanism 2 It is connected with the cantilever feeding belt conveyor 1 through a mechanical buckle. The feeding mechanism 2 includes a feeding platform 201 that is buckled and connected to the cantilever feeding belt conveyor 1. The feeding platform 201 is provided with a feeding hopper 202. The both sides of material platform 201 are all provided with platform slope plate 203, the inside of loading hopper 202 is provided with chute, and the bottom end of chute is provided with funnel, and the inside of feeding hopper 202 is provided with slide plate, and the inside of chute plate is provided with Wear-resistant liner, the wear-resistant liner is set to protect the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com