Lipstick and preparation method thereof

A technology of lipstick and isostearate, applied in the field of lipstick and preparation, can solve the problem that the glossiness of the lipstick cannot meet the requirements of consumers, etc., and achieve the effects of good upper lip melting feeling and good smearing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The embodiment of the second aspect of the present invention provides a kind of preparation method of lipstick, comprises the following steps:

[0031] Take each component according to the mass percentage;

[0032] Heat phase A and phase B to 85°C-90°C, completely melt to a transparent state, and mix well to obtain the first mixture. The phase A includes polyethylene wax, candelilla wax, beeswax and ceresin wax; The B phase includes pentaerythritol tetraisostearate, polyisobutene, polyglyceryl-2 triisostearate, hydrogenated polyisobutene, jojoba seed oil, shea butter, phenyl silicone oil raw materials and alcohols, The alcohols are bis-behenyl alcohol or isostearyl alcohol or phytosterol dimer linoleyl alcohol dimer linoleate alcohol;

[0033] Gradually add phase C to the first mixture, after grinding evenly, heat to 85°C-90°C, mix uniformly to obtain the second mixture; the phase C includes: CI77891, CI45410 and CI15985;

[0034] Cool the second mixture to 80°C, add ...

Embodiment 1

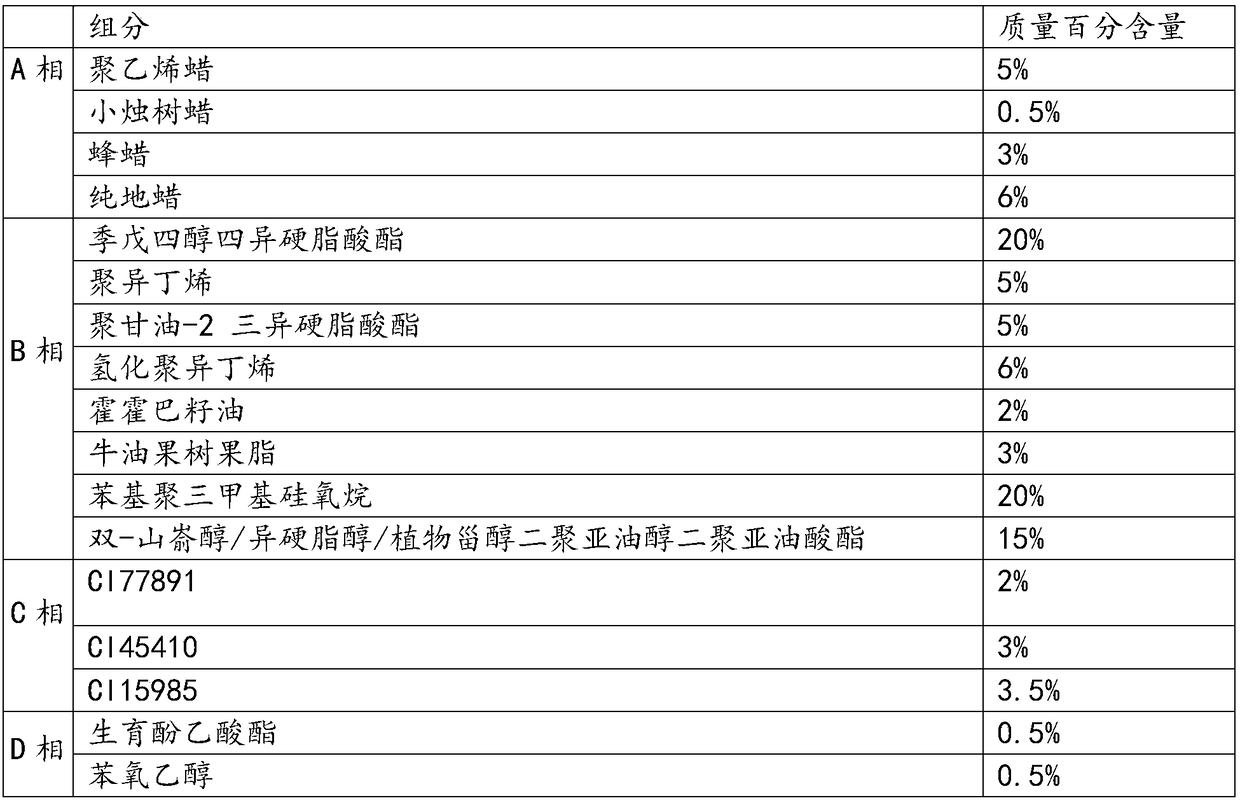

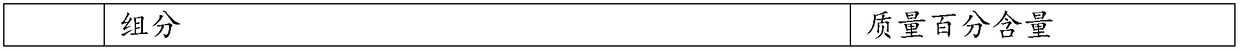

[0038] A preparation method of high-gloss lipstick, characterized in that: by weight percentage, comprising the following components,

[0039] See Table 1 for details

[0040] Table 1

[0041]

[0042] Prepare the raw materials according to the formula ratio:

[0043]Heat phase A and phase B to 85°C-90°C, completely melt to a transparent state, and stir evenly to obtain the first mixture;

[0044] Take part of the first mixture and add it to the three-roll mill, gradually add phase C, grind it evenly, heat it to 85°C-90°C while stirring, and mix it evenly to obtain the second mixture;

[0045] Cool the second mixture to 80°C, add phase D to the second mixture, and stir evenly to obtain the third mixture;

[0046] The third mixture is heated to 85°C-90°C, poured into a mold, cooled to -5°C, frozen for 10 minutes, molded and demolded to obtain a product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com