Oil emulsion vaccine and preparation method thereof

A technology of oil emulsion and vaccine, which is applied in antiviral agents, pharmaceutical formulations, emulsion delivery, etc., can solve problems such as difficulties, and achieve the effects of reducing retention, strong ability to induce antibody production, and strong ability to induce antibody production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

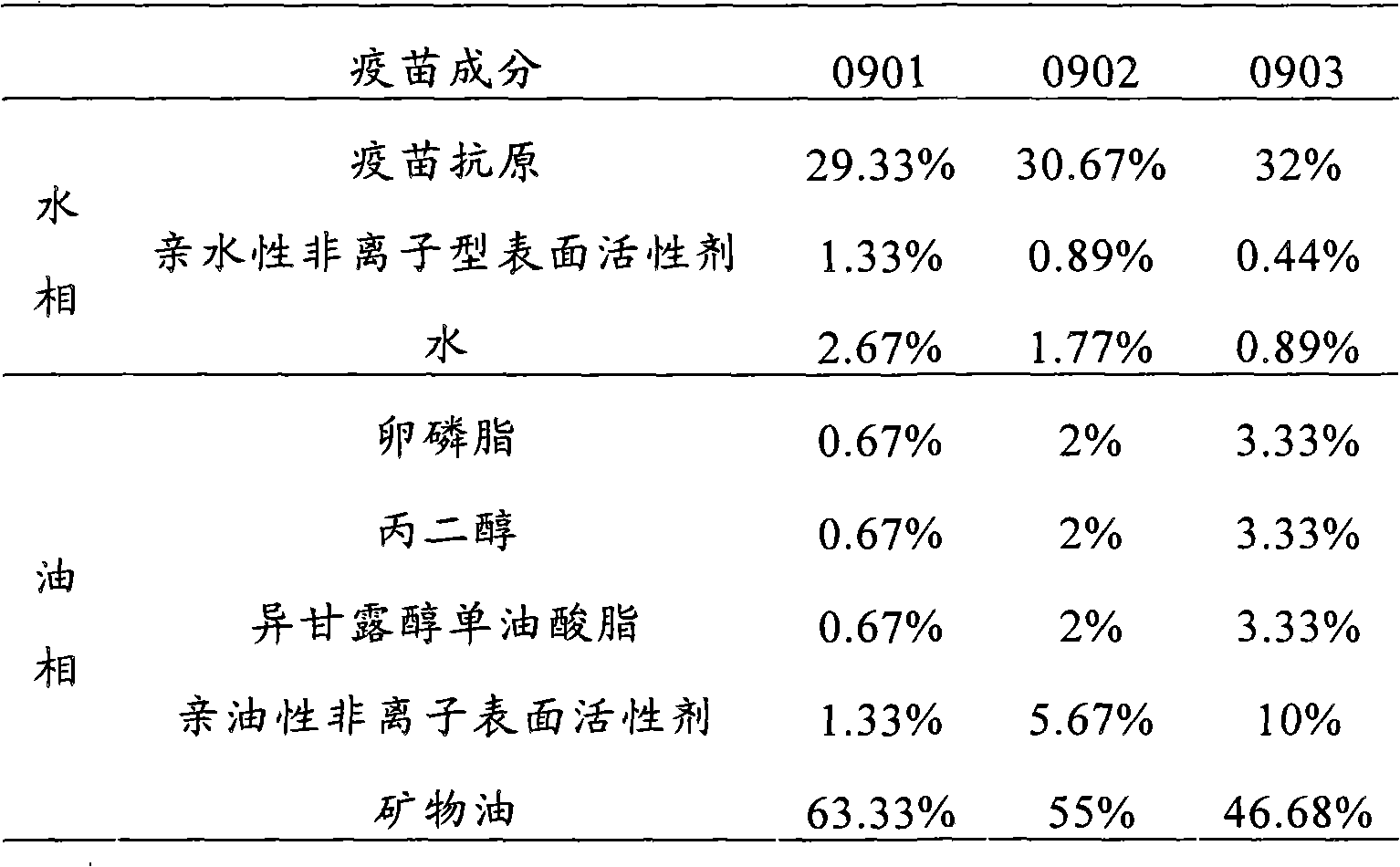

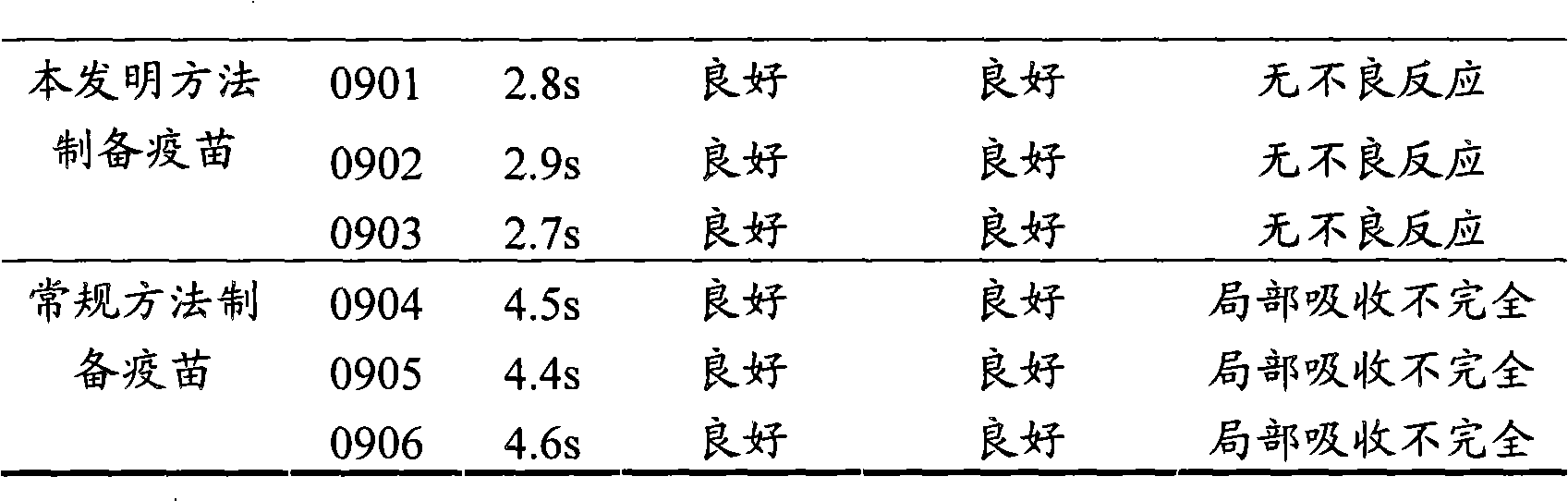

[0037] Embodiment 1 method of the present invention and conventional method prepare Newcastle disease vaccine and comparative test thereof

[0038] One. The inventive method prepares Newcastle disease antigen oil emulsion vaccine

[0039] 1. Dilute the hydrophilic non-ionic surfactant Tween-80 with water to 3 times volume, then autoclave at 121°C for 30 minutes and cool to room temperature for later use; The immune antigen was mixed evenly with Tween-80 diluted with 3 times the volume of water and sterilized at 121°C for 30 minutes to form the aqueous phase.

[0040] 2. Mix white oil, propylene glycol, lecithin and isomannide monooleate as an adjuvant, then mix with Span-80 to form an oil phase, sterilize by autoclaving at 121°C for 30 minutes, and cool to room temperature for later use.

[0041] 3. According to the volume ratio of oil phase: water phase = 2:1, first pour the oil phase into the emulsification tank, the stirring speed is 11,000rpm, and the temperature is 18°C,...

Embodiment 2

[0071] Embodiment 2 method of the present invention and conventional method prepare avian influenza vaccine and comparative test thereof

[0072] One. The inventive method prepares avian influenza antigen oil emulsion vaccine

[0073] 1. Dilute the hydrophilic non-ionic surfactant Tween-80 with water to 3 times the volume, then autoclave at 121°C for 30 minutes and cool to room temperature for later use; take poultry with a hemagglutination (HA) titer of 9log2 Influenza antigen and Tween-80 diluted with 3 times the volume of water and sterilized under high pressure at 121°C for 30 minutes were evenly mixed to form the water phase.

[0074] 2. Mix white oil, propylene glycol, lecithin and isomannide monooleate as an adjuvant, then mix with Span-80 to form an oil phase, autoclave at 121°C for 30 minutes, and cool to room temperature for later use.

[0075] 3. According to the volume ratio of oil phase: water phase = 2:1, first pour the oil phase into the emulsification tank, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com